The Internet of Things (IoT) is promising major operational benefits by closing the gap between production and IT. It presents an opportunity for the data we generate for manufacturing control to be shared with Internet-based applications to bring enterprise-wide advantage.

In automation, the benefits could include higher efficiencies, greater up times, faster repairs, and higher quality. More significant benefits could arise however if Industrial IoT can deliver fresh insights into how our plants work and enable us to operate them in better ways.

Hilscher has long been associated with connectivity solutions for the popular protocols found on the factory floor. Our own netX chip was designed with that in mind. It turns out that netX is an ideal interface for IoT too.

The netX chip family provides easy interfacing to the many different networking protocols we see on our plants today. It supports 17 network protocols with 33 different master and slave stacks, all utilizing a common software and hardware interface, making it simple to integrate Fieldbus and Ethernet networks.

Leverage communication standards

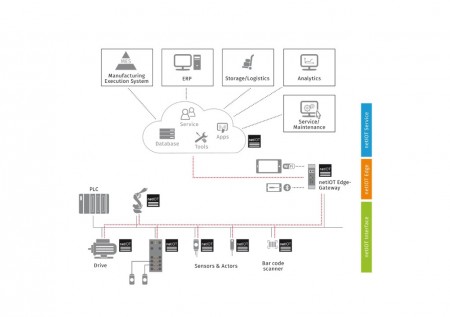

Whether you call it IoT, Industrial Internet or Industry 4.0, all require end-to-end data communication from the sensor into the cloud. And where’s the data? On the wire! What’s needed is a way to move field-level data from existing manufacturing networks to the cloud-based applications. The Hilscher approach is for “Industrial Cloud Communication” and netIOT™ is the family name for our IoT products and services.

In summary they are:

- netIOT™ Interface: A chip-based module allowing IoT data to be gathered directly from the lowest level devices such as field sensors.

- netIOT™ Edge: Gateways for securely transmitting data from existing networks into the cloud.

- netIOT™ Service: Applications based on partnerships with IT-centric cloud-based suppliers supplying remote processing capabilities.

At the device interface level, the netIOT™ is a DIL-32 embedded module for field sensors and instrumentation, and it places IoT functionality right at the point of measurement. It is equipped with an OPC UA server and an MQTT client in addition to its communications components. This makes it possible to access a field device via the TCP/IP channel of an Industrial Ethernet network using the same physical cables but without PLC involvement.

The netIOT™ Edge-Gateways securely couple existing automation networks to a cloud. They are also the main configuration element for netIOT™ field devices – e.g. for the parameterization of sensors  and actuators—and they offer easy access for diagnostics. Web-based monitoring is supported and wireless connectivity opens up remote access to mobile devices, so it becomes possible to read and load configurations using mobile devices such as tablets and smart phones.

and actuators—and they offer easy access for diagnostics. Web-based monitoring is supported and wireless connectivity opens up remote access to mobile devices, so it becomes possible to read and load configurations using mobile devices such as tablets and smart phones.

An important part of the netIOT™ solution are the integrated tools offered to popular cloud platforms. For Hilscher’s netIOT™ Edge-Gateways, there is already a connection to IBM’s Bluemix cloud platform, with its range of powerful applications options. More connections will be formalized soon.

Hilscher’s solutions make IoT transparently available to all users today. They are the most sophisticated third-party approach to Industrial Internet yet seen in automation and they make the benefits of IoT readily accessible to anyone.

Click here to read the complete whitepaper.

Armin Pühringer, Business Development Manager, Hilscher Gesellschaft für System Automation mbH