CIAT Application Story

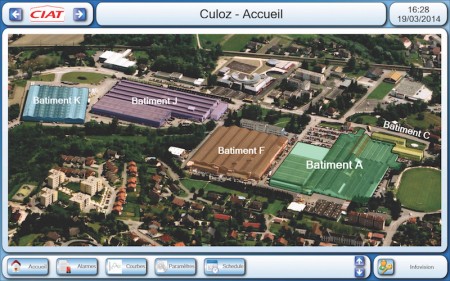

CIAT, situated in the Rhone-Alpes region of France in Culoz, has been an expert producer of air conditioning, refrigeration and heating units for 80 years. CIAT is a market leader in sustainable solutions for heat exchange and air handling and continues to be a trusted resource for comfort, air quality and energy optimization. The company is dedicated to the environment and in using energy wisely, with all its products and facilities in accordance with local environmental agency provisions.

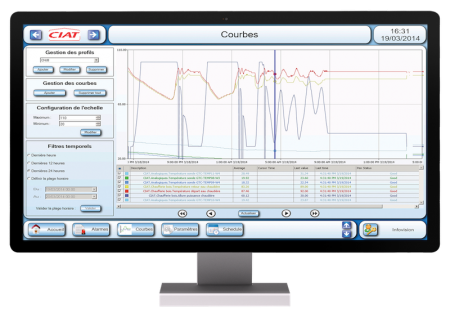

CIAT decided it was time to investigate 64-bit monitoring systems that aligned with their values for innovation and sustainability. This search ultimately led them to ICONICS due to its best-in-class 64-bit solutions, Microsoft Gold certification, and Web-client connectivity, as well as the scalability of its solution. CIAT implemented ICONICS’ GENESIS64™, ScheduleWorX™, BridgeWorX™, WebHMI™ and OPC UA Server Suite, along with Microsoft SQL Server, across their entire building following a three-month pilot program.

CIAT decided it was time to investigate 64-bit monitoring systems that aligned with their values for innovation and sustainability. This search ultimately led them to ICONICS due to its best-in-class 64-bit solutions, Microsoft Gold certification, and Web-client connectivity, as well as the scalability of its solution. CIAT implemented ICONICS’ GENESIS64™, ScheduleWorX™, BridgeWorX™, WebHMI™ and OPC UA Server Suite, along with Microsoft SQL Server, across their entire building following a three-month pilot program.

CIAT was also impressed with the unification and standardization of communications with all their equipment (e.g. meters, compressors, etc.) through OPC technology. ICONICS software provided the ability to integrate information from a broad range of equipment and systems used without breaking existing connections.

ICONICS’ GENESIS64 HMI/SCADA was one of the first solutions in its industry to achieve OPC UA Client Lab Certification from the OPC Foundation. GENESIS64’s integration with OPC UA makes it easy to visualize virtually any equipment, process, operation or business data.

With seven buildings of 92,000 square meters of office and production space, CIAT used ICONICS to centralize the Culoz servers, access data remotely via Ethernet, view monitoring and consulting reports via the Web, and control devices on a set schedule. They were also able to reach their sustainability goals through ICONICS’ 64-bit technology. Using OPC technology, CIAT can now interface with MobiCall, Europe’s leading unified event communication service, as well. CIAT has been very pleased with the tremendous success of the ICONICS system.

With seven buildings of 92,000 square meters of office and production space, CIAT used ICONICS to centralize the Culoz servers, access data remotely via Ethernet, view monitoring and consulting reports via the Web, and control devices on a set schedule. They were also able to reach their sustainability goals through ICONICS’ 64-bit technology. Using OPC technology, CIAT can now interface with MobiCall, Europe’s leading unified event communication service, as well. CIAT has been very pleased with the tremendous success of the ICONICS system.

ICONICS Embraces OPC UA for IoT Gateway Connectivity

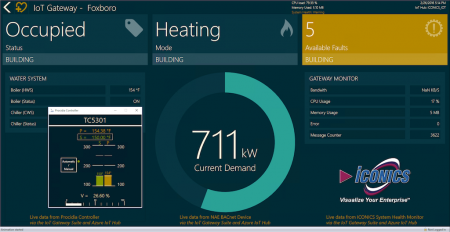

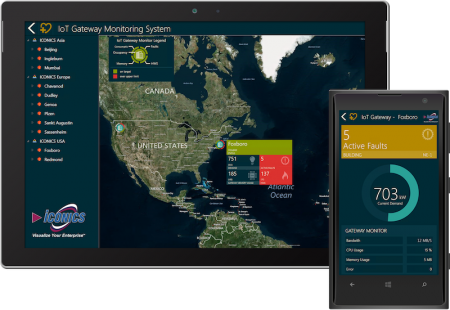

ICONICS recently introduced its new IoT Gateway Suite, and enhanced integration with the next generation of Microsoft Azure cloud platform and services, at Hannover Fair 2016. ICONICS’ IoT Gateway Suite communicates with Azure applications using the most popular transport protocols. Once the IoT Gateway is online, it connects to Microsoft Azure IoT Hub so that it can authenticate, transmit, and receive data. Acting as a secure message broker, the Microsoft Azure IoT Hub allows for remote device management, provisioning, and configuration.

Such cloud-enabling technologies greatly simplify the deployment of IoT applications that will scale and be future-proof.

Russ Agrusa, President and CEO, ICONICS.

The IoT Gateway Software Suite is ICONICS’ launch pad for a new software architecture for its visualization, analytics and mobile solutions based on Microsoft Azure Service Fabric and microservices. With Service Fabric, ICONICS is utilizing Azure as a true platform as a service (PaaS) to deploy and scale applications for the new era of Industrie 4.0 and IoT deployments. The real power of IoT gateways is in the implementation of low-cost hardware devices that can be placed in remote locations or just about anywhere there is information to be sent to Azure.

Configuration of the ICONICS IoT Gateway Software Suite includes onboard industrial, energy management, and building protocols. In addition to integration with BACnet, Modbus, SNMP and Web Services protocols, ICONICS made sure to include the OPC Unified Architecture (OPC UA), allowing for a standard model of plant floor integration with the enterprise. [Note: ICONICS is a charter member of the OPC Foundation and has assisted the foundation over the years by providing source code and hosting interop studies, as well as serving on the board of directors for the foundation.]

The emergence of OPC UA was a technological breakthrough in that the architecture / specification provided a means for disparate industrial equipment and systems to communicate. A factory with multiple pieces of manufacturing hardware and IT devices now had a bridge for site-wide connection, making data visualization, monitoring, control and analysis easier than it had ever been. Today, the wide acceptance and use of the Industrial Internet of Things (IIoT) is a corresponding technological breakthrough. Adopters of OPC UA can utilize cloud integration to scale operations when necessary, ensure against IT hardware obsolescence, and provide global access to connected systems. Integrating OPC UA with the IIoT helps companies to visualize, analyze and mobilize their data without incurring additional IT infrastructure that may require more money, maintenance, repair and upgrades.

The emergence of OPC UA was a technological breakthrough in that the architecture / specification provided a means for disparate industrial equipment and systems to communicate. A factory with multiple pieces of manufacturing hardware and IT devices now had a bridge for site-wide connection, making data visualization, monitoring, control and analysis easier than it had ever been. Today, the wide acceptance and use of the Industrial Internet of Things (IIoT) is a corresponding technological breakthrough. Adopters of OPC UA can utilize cloud integration to scale operations when necessary, ensure against IT hardware obsolescence, and provide global access to connected systems. Integrating OPC UA with the IIoT helps companies to visualize, analyze and mobilize their data without incurring additional IT infrastructure that may require more money, maintenance, repair and upgrades.

IoT Gateways provide the bridge between an on premise communications network and a cloud-based communications network. Sometimes referred to as an “Edge device”, an IoT gateway provides “Southbound” data connectivity to end devices, completely on premise. It also has a “Northbound” communication path that provides data connectivity between itself and the cloud. In the case of the process and factory automation industries, the Southbound communications protocol is typically an industry standard protocol, such as OPC UA, although it can also be a proprietary communications protocol as well. The Northbound communication path needs to be highly secure and is often based on a publish/subscribe (“pub/sub”) mechanism. Emerging communication protocols being used for this include Message Queuing Telemetry Transport (MQTT) and Advanced Message Queuing Protocol (AMQP).

IoT Gateways provide the bridge between an on premise communications network and a cloud-based communications network. Sometimes referred to as an “Edge device”, an IoT gateway provides “Southbound” data connectivity to end devices, completely on premise. It also has a “Northbound” communication path that provides data connectivity between itself and the cloud. In the case of the process and factory automation industries, the Southbound communications protocol is typically an industry standard protocol, such as OPC UA, although it can also be a proprietary communications protocol as well. The Northbound communication path needs to be highly secure and is often based on a publish/subscribe (“pub/sub”) mechanism. Emerging communication protocols being used for this include Message Queuing Telemetry Transport (MQTT) and Advanced Message Queuing Protocol (AMQP).

In fact, the OPC Foundation has identified AMQP as one of its protocols of choice upon which to build a reference implementation of Enterprise Service Bus (ESB) connectors, which serves as the basis for its IoT platform. As a charter member of the OPC Foundation, ICONICS plans to support AMQP because of its efficient design, which is optimized for messaging between devices.

ICONICS offers two options to deploy the IoT Gateway Suite, based on the complexity and cost considerations of a particular application. Both options support read and write capabilities via AMQP.

- The IoT Gateway Suite Enterprise is based on Windows 10 IoT Enterprise and supports OPC UA and OPC Classic (as well as BACnet, Modbus, SNMP, and Web Services). The application load can be higher due to more performant processors (e.g. Intel Atom or even I5 or I7 used by automation OEMs).

- The IoT Gateway Suite Core is based on Windows 10 IoT Core and supports OPC UA (as well as simple I/O operations, Modbus, and Web Services). The application load is lower, as the IoT gateways rely on less performant processors (e.g. Intel Quark or ARM). The target applications are typically cost-sensitive with higher quantities.

ICONICS IoT Gateway Suite delivers multiple features for industrial automation customers including equipment monitoring, predictive maintenance and operational efficiency solutions for manufacturing, water & wastewater, oil & gas, automotive, food & beverage, pharmaceutical and many other industries. It enables rapid access to operational dashboards with real-time key performance indicators (KPIs) for OEE, downtime, quality and production.

ICONICS offers a number of additional materials and resources to help in decision-making for IoT-related software solutions. Visit www.iconics.com/IoT for a collection of case studies, videos and whitepapers, as well as additional product information.