Weber Integrates OPC UA into Slicing Machines

Weber Maschinenbau GmbH produces groundbreaking systems to process, refine, and slice sausages, meat, cheese, and other food. Weber is world market leader in the field of Slicer technology. Its customers are amongst others large meat companies, dairy factories, and system catering businesses.

Special innovations from the current portfolio are the Weber Slicer equipped with circular or curved blades and the Weber Pick Robot for assembling sliced sausage or cheese in packages. The new Weber Variety Pack provides fully automatic combination of several varieties of sausage, cheese, or snacks in a single package. The modular system combines several Slicers with a conveyor belt system and additionally provides different infeeding variants. The central machine, the so-called Slicer is always surrounded by various different models of Weber machines. Hereby, the Slicer is always combined with one or more machine modules, like scanner, peeling machine, (optical) scale, interleaver, underleaver, multi-layer buffer, infeeder, robot etc. In multi variety lines, i.e. facilities in which e.g. different varieties of cheese are put in a single package, three or more slicers may be combined in a single facility and thus form most complex combinations.

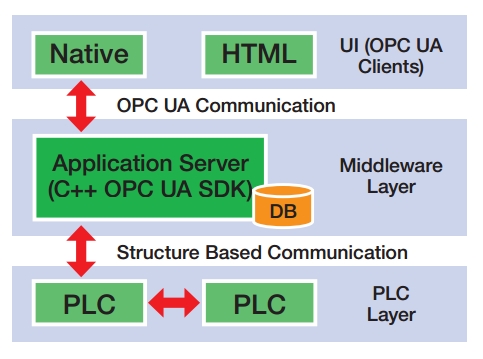

Weber’s aim was to equip the machines with a new SCADA system, whereby existing machinery should use the new functionality of updated modules right away. The new architecture should be based on a backbone, providing a middleware on an industrial PC which is able to map all business processes of the machine(s). Existing “classic” applications should be encapsulated where necessary and linked up with new features. In parallel, new functionality should be provided. In short, Weber wanted to develop a modern SCADA system, forming a reliable basis for process control systems and, fist of all, provides a standardized interface for clients.

In search for a standard which is able to connect machine building and IT, Weber discovered OPC UA. It contains all components which are required for software engineering within machine and plant engineering at the moment. The implemented OPC UA interface forms the link to all clients communicating with the machines. This can be e.g. local or remote clients to operate machines, business software (MES/ ERP), or (own) process control systems. By strictly separating communication from mapping of business processes in the middleware, it has been possible to develop the particular software layers of the application almost independently. Thanks to OPC UA it has been possible to fulfill all requirements and create a future-proof backbone for the machine software of Weber Maschinenbau GmbH.

The decision for a solution based on OPC UA using a central middleware was driven by different requirements. On the one hand, an application server should be created, preferably completely implemented in C++, for being able to concentrate on the complex business processes. Services like authentication/authorization (i.e. user management plus access via certificate and user/password) should be already available, as well as a yellow pages service (browsing), historical management, (encrypted, synchronous, asynchronous) communication, and object orientation (methods, properties, events). On the other hand, a standardized interface for clients should be used, which is closely related to machine and plant building. OPC UA is well-established in the field of industrial automation and widely spread in many HMI/SCADA systems as well as in programmable logic controllers. Weber have used the C++ based OPC UA SDK/Toolkit from Unified Automation to develop the OPC UA middleware. It contains a base library which hides the OPC UA Stack of the OPC Foundation with a convenient interface. Thus, it is possible to highly simplify development effort and to enable an efficient integration into existing applications. Besides simplifying the UA Stack APIs, the SDK implements common UA functionality which is needed by most or all UA applications. It provides generic functions and helper classes, implements security handling, and illustrates common use cases with the help of examples. The SDK is complemented by UaModeler, a tool for graphically modeling the address space, which is also able to directly generate source code matching the SDK.

The decision for a solution based on OPC UA using a central middleware was driven by different requirements. On the one hand, an application server should be created, preferably completely implemented in C++, for being able to concentrate on the complex business processes. Services like authentication/authorization (i.e. user management plus access via certificate and user/password) should be already available, as well as a yellow pages service (browsing), historical management, (encrypted, synchronous, asynchronous) communication, and object orientation (methods, properties, events). On the other hand, a standardized interface for clients should be used, which is closely related to machine and plant building. OPC UA is well-established in the field of industrial automation and widely spread in many HMI/SCADA systems as well as in programmable logic controllers. Weber have used the C++ based OPC UA SDK/Toolkit from Unified Automation to develop the OPC UA middleware. It contains a base library which hides the OPC UA Stack of the OPC Foundation with a convenient interface. Thus, it is possible to highly simplify development effort and to enable an efficient integration into existing applications. Besides simplifying the UA Stack APIs, the SDK implements common UA functionality which is needed by most or all UA applications. It provides generic functions and helper classes, implements security handling, and illustrates common use cases with the help of examples. The SDK is complemented by UaModeler, a tool for graphically modeling the address space, which is also able to directly generate source code matching the SDK.