SPONSORED BY: OMRON

The number of OPC UA products that can be easily and securely connected is spreading.

Multi-vendor installations of secure production systems corresponding to the international standard OPC UA are spreading. This article introduces an example of the OPC UA products that are used in these systems.

OPC UA Server

PLC and Controller

Omron and major PLC and controller manufacturers worldwide offer products with the OPC UA server interface. The NX102/NX701/NJ501 Series Machine Automation Controllers support the PLCopen information model and are built-in OPC UA Server certified by the OPC Foundation as standard. This allows the controller to be directly connected to a high-level IT system, such as SCADA, by simply selecting the controller variables.

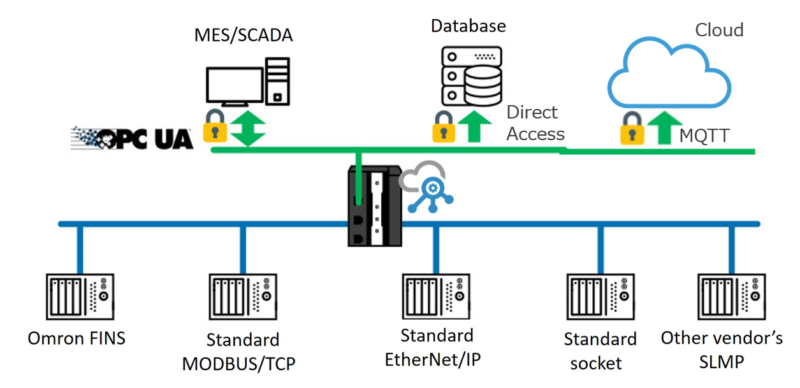

The NX102/NX701 Series comes equipped with database connection functionality as well as OPC UA server functionality. One controller can be connected to both the higher-level system and database: MES or SCADA via OPC UA, and SQL Server or Oracle Database used for traceability via database connection.

The NX102/NX701 Series comes equipped with database connection functionality as well as OPC UA server functionality. One controller can be connected to both the higher-level system and database: MES or SCADA via OPC UA, and SQL Server or Oracle Database used for traceability via database connection.

The NX102 Controller supports not only OPC UA and database connection but various networks including EtherNet/IP, EtherCAT, MODBUS/TCP, and SLMP. It also offers IO-Link connectivity that makes communication down to the sensor level visible. Combining versatile connectivity with OPC UA brings IT and IoT to manufacturing sites.

OPC UA Client

This section shows some examples of software with an embedded OPC UA client that is used together with an OPC UA server such as PLC.

(Note: Connection to the software packages mentioned below has been confirmed in the interoperability workshops (IOP) held by the OPC Foundation. However, this does not mean that Omron recommends these products or guarantees the connection.)

AVEVA Edge (Formerly InduSoft Web Studio)

This is a SCADA provided by AVEVA. There are many cases where it is connected and installed with OMRON PLCs.

https://www.aveva.com/en/products/edge/

FANUC MT-LINKi

PC software provided by FANUC Corporation for collecting and visualizing the machine information in the factory.

https://www.fanuc.co.jp/en/product/cnc/f_mt-linki.html

Information can be collected from equipment such as machine tools with FANUC CNC, FANUC robot controllers, and PLCs supporting OPC UA.

OSIsoft PI System

This product offered by OSIsoft is an IoT platform that can collect, accumulate, and manage huge amounts of data in real time. PI Connector for OPC UA enables real-time data collection from the OPC UA server such as PLC. See the demonstration video of Omron’s NX102 Controller connected with PI System.

Puerto UA Monitor

Puerto Co., Ltd. in Japan provides Excel add-on OPC UA client.

Data can be read from or written to the OPC UA server like a PLC in the familiar Excel environment.

See the demonstration video of Omron’s NX102 Controller connected with Puerto UA Monitor.

Node-RED

Node-RED is an open-source software (OSS) visual programming tool developed by the OpenJS Foundation project, which allows you to program on a web browser, create IoT applications, and display data. See the demonstration video of Omron’s NX102 Controller connected with Node-RED.

TeslaSCADA / TeslaSCADA2

This is a SCADA for Android and iOS devices provided by LLC Tesla. It can collect and display data in real time from OPC UA servers such as PLCs from mobile devices running Android and iOS. A demonstration of the connection between OMRON NX102 controller and TeslaSCADA2 is available as a video.

Factory I/O

This is a PLC training software with 3D simulation provided by Real Games. A demonstration of Omron NX102 controller connected to Factory I/O is available in the video.

Practical Benefits to using OPC UA

Once again, let’s look back at the benefits of using OPC UA in an industrial automation system. There are three major benefits:

- Multi-vendor – Since it is a manufacturer-independent interoperability standard, it is possible to connect to each other without considering the manufacturer. You can adopt the product with more confidence if the products are certified by OPC Foundation. List of certified OPC products: https://opcfoundation.org/certified-products.

- Easy to connect – OPC UA provides a unified modeling function called “information model” that represents information and functions to realize the information linkage between multiple vendors. The information model is the model that properly classifies the information to be exchanged, gives it meaning, and expresses it as a block or module like a template. For example, a controller that complies with the international PLC standard IEC 61131-3 (PLCopen) can be expressed as a structure variable. Then, the actual data is exchanged by specifying the structure variable name or member name. This simplifies allocation and also makes it easier to utilize the information since the structure and meaning of the information can be easily communicated. The following is a video showing the setting of the controller NX102 of OMRON as an example of the setting of OPC UA.

The system integrator who actually used OPC UA in the SCADA system said, “Because I just assigned the variables of the PLC as the tags of SCADA as it is, the amount of time and errors of the setting work could be reduced greatly.”

- Security support – OPC UA adopts the security technology that is used as a standard in the Internet, and meets the three major requirements of security: integrity, confidentiality, and availability. OPC UA achieves data verification using digital signatures, strong encryption of messages, and connects FA and IT securely. One of the reasons why OPC UA is recommended as a standard communication for Industrie 4.0 is that it supports secure connection and data transmission.

Minoru OKA

Minoru OKA

Global product manager, Controller

Omron

Company names and product names in this document are the trademarks or registered trademarks of their respective companies.