by Martin Cavanaugh

The Society of Petroleum Engineers has formed a technical section to accelerate the development and implementation of automated drilling systems. Automated drilling systems are intended to increase the productivity of drillers, while at the same time increasing safety for both humans and the environment.

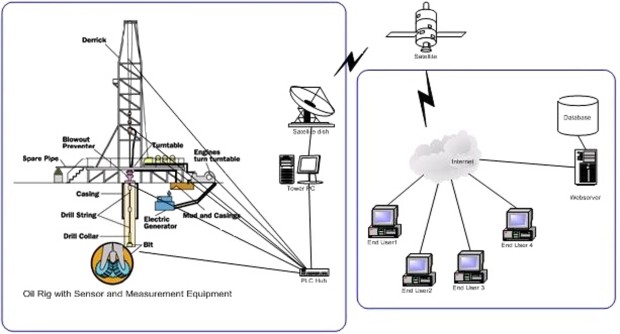

The Drilling Systems Automation Technical Section (DSA-TS) committee supports initiatives which identify the technologies, recommend best practices, standardize nomenclature, and help define the value of drilling systems automation. One of the key technologies identified by this committee is the use of OPC UA for device communications and control. The current device communications on a drilling rig are seen below in Figure 1.

Figure 1 – Current rig device communications (after RigManager webpage)

Each individual rig device communicates to a rig PLC. An automation PLC communicates with the rig PLC to control the devices through exposed setpoints. As the flavor of rig PLC varies from rig to rig, portable automation control programs are not possible. Data access from the rig PLC is generally provided as a passive, one-way data stream.

The use of OPC UA provides the following functionality to the automation engineer:

- A standard and secure bi-directional network protocol for device communications

- The ability to model each rig device as a structured object

- A standard , portable interface for data query and controlling devices

- Historization capabilities

- Device discovery, allowing for plug-and-play rig components

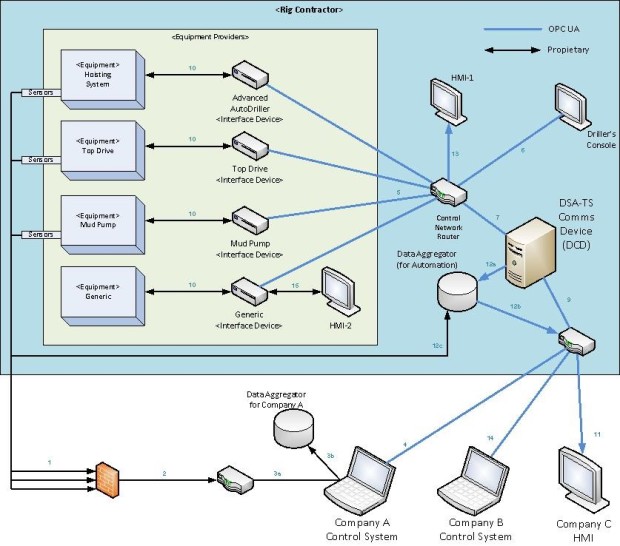

Using OPC UA allows each rig device to maintain all the information about itself and expose it through a UA server. The device communications architecture now becomes standardized as seen below (Figure 2), where the Machine Interface Device can be PLC controller with an embedded OPC UA server.

Figure 2 – Rig device communications

The architecture for an automated rig can be seen in Figure 3. Such a system allows for portable, machine independent, OPC UA Clients to function as both data-to-information converters and automation algorithms. Besides the benefits for drilling automation, there are improvements in rig construction as a result of the simplified device control architecture.

Figure 3 – Automated rig architecture

In summary, OPC UA provides an off-the-shelf, standard communications framework which can reduce the cost and complexity of implementing automation to the drilling industry.