By David Hill, Opto 22

Heavy-industries conglomerate reduces energy and maintenance costs by integrating energy data with ERP system via OPC.

Challenges

A large heavy-industries corporation in Asia supports economic development worldwide by providing basic industrial materials and by building the facilities needed for industrial growth. The company’s portfolio of products includes castings and forgings, nuclear and thermal power plants, water desalination plants, material handling systems, and more. Products and components are manufactured in multiple sub-factories, and a large quantity of electricity, gas, and water is consumed by each facility in the process. The amount of energy used varies in each sub-factory based on the manufacturing requirements of the products produced.

In order to monitor the total energy used company wide and by each sub-factory, the company started to track energy consumption data. However, the energy data was collected manually from electrical, gas, and water meters at each sub-factory, thus creating some problems. First, the energy data was not continuously recorded and was not available in real time. Second, the collected data had to be logged manually into the company’s enterprise resource planning (ERP) system used for analysis. This was a time-consuming step that made it difficult to determine quickly how much energy each sub-factory consumed. Lacking recent energy data, the energy costs assigned to each sub-factory were calculated by dividing total energy cost by the number of sub- factories.

Solutions

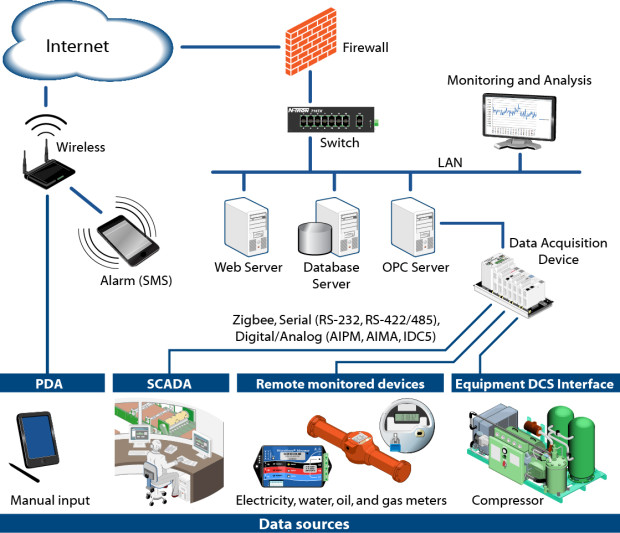

It was clear that real-time electricity, gas, and water consumption data for each sub-factory had to be captured in an electronic form that was available to the ERP system for analysis. To implement this, the company worked with Opto International, Korean national distributor for industrial controls manufacturer Opto 22. Opto International collaborated with system integrator Enforce/ Daewoo Information and Technology to design and install a data acquisition system for each sub-factory.

Due to the Opto 22 equipment’s built-in OPC support plus its support for additional protocols including Modbus, EtherNet/IP, HART, Profibus, and BACnet, Opto 22’s SNAP PAC System was selected as the control platform. Opto 22 SNAP I/O modules were chosen to collect signal data in real time from gas, water, and electrical meters, as well as generators and other devices located throughout each sub-factory. Once acquired by the SNAP PAC System, the energy data was made available via an OPC server—in this case Opto 22’s OptoOPCServer—to the company-wide ERP system for logging and analysis.

Results

Two types of cost savings have resulted from these efforts. First, using precise, real-time energy data to identify potential areas of savings, the company reduced its overall facility energy cost by 5%. The cost of maintaining standby energy also dropped by 3%. Another cost savings was found in reducing the labor required to collect the energy consumption data. Time needed to acquire the data decreased 3 man-months per year, while the time needed to log the data manually dropped 8 man-months per year. In the future, the corporation plans to add control of field equipment to the energy monitoring system, and also to expand its use into projects such as wastewater control systems.

Learn more about Opto 22.