Excerpted from an article on the Microsoft Blog by Rohit Bhargava, CTO, WW Manufacturing & Resources, Microsoft Corporation :

While IoT standards and interoperability are likely to be subjects of ongoing debate and discussion over the next few years, there are already well-established standards in industrial and manufacturing environments that can accelerate the shift to outcome-based models. Leveraging these standards in place, together with new IoT capabilities, enables companies to deliver new value-added services without waiting for long term retrofits of the industrial base. And there are very real risks for those organizations who move too slowly to embrace this change.

In fact, OPC Unified Architecture (OPC UA) is a platform independent service oriented architecture that provides standard models for secure and reliable information exchange in industrial automation across a range of manufacturing and resource industries. Developed by the OPC Foundation, OPC UA has long been an established standard for data exchange and interoperability between factory-level devices, supervisory and control systems, manufacturing execution systems, and enterprise applications such as ERP and SCM. As a vendor independent international standard it is also published as the IEC 62541 specification.

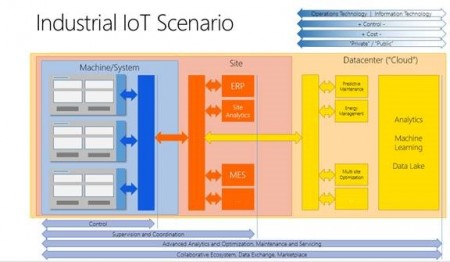

Industrie 4.0 and IIoT require contiguous communications of data through all layers and levels in the digital factory, extending to enterprise systems, as well as externally to cloud-based services and other Internet services. With more than 10,000 OPC products available in the marketplace today, and deployments estimated to be in the tens of millions of instances, OPC UA enables companies to get started on business transformation today.

With the breadth of this legacy installed base across the global industrial landscape, together with the familiarity of OPC technologies in the manufacturing ecosystem, it stands to reason that the OPC standard can accelerate transformation in these environments through next generation IIoT applications based on data aggregation at scale, advanced analytics, machine learning, and new forms of human-machine interaction.

Furthermore, Rohit had this to say about OPC UA:

OPC-UA plays a critical role in opening up new op- portunities across manufacturing as data from con- nected products, devices, and sensors increasingly becomes the fuel for insights, productivity , and new business models in an IoT world. In keeping with our commitment to openness and collaboration, Mi- crosoft is fully committed to supporting OPC-UA and its evolution in a rapidly transforming OT/IT land- scape.

More of which can be found in the IoT / Industrie 4.0 OPC UA brochure.