SPONOSORED BY: TAKEBISHI Corporation

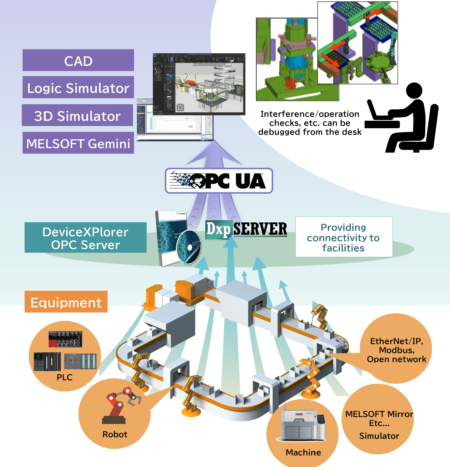

DeviceXPlorer OPC Server, the OPC server from Takebishi, has announced support for MELSOFT Mirror, the logic simulator from Mitsubishi Electric. This allows the entire behavioral system of production lines to be tested from the desk without the actual control devices. Simulator software like MELSOFT Mirror, as well as MELSOFT Gemini, a 3D Simulator which enables verification without the need for actual devices, are becoming increasingly popular. The time saved in testing and deployment allows manufacturers to focus on digital transformation, honing their competitive edge. This case study focuses on the use of OPC UA to achieve Digital Twin realization, a core technology of Industry 4.0.

The Merits of Utilizing Simulation Software

With the goal of reducing development working hours, there is an increasing need for the utilization of simulation software. Its uses include simulating the movement paths and operating rates of humans, robots, and AGVs, pre-checking the robot interference, and verifying the control logic of the connected control device. By using simulation software, it is possible to perform offline programming verification and debugging with a virtual environment. Developers do not need to worry about hardware-related lead times or building physical wiring, and they can conduct pre-checks of machine operations within the production line, debug and optimize the workflow by task.

A New Approach to Virtual Commissioning Using OPC

While simulation software continues to spread, current factories contain machinery and equipment from many different vendors, and many of these devices cannot be covered by simulators alone. This is where DeviceXPlorer OPC Server, which can communicate with a wide range of devices and convert data into OPC, expands the functionality of simulation software. Traditionally, OPC has facilitated the mutual sharing of data between different vendors’ equipment or systems. Simulation software with OPC through DeviceXPlorer OPC Server can flexibly access any system, and configure a solution to meet the specific needs of the user.

Guaranteeing Compatibility Between Various Vendors’ Equipment and Simulation Software

MELSOFT Mirror, a logic simulator from Mitsubishi Electric, is a software that that can simulate the entire control system of a manufacturing site. Building in the simulation environment makes hardware unnecessary, allowing for extensive debugging and reducing the development work-hours for debugging on the production line. Actual machines and physical connections are not required, which reduces the need for reworking during implementation. Since DeviceXPlorer OPC Server can connect with both MELSOFT Mirror and the actual machine from not only Mitsubishi PLCs but also many different PLCs, the configuration time required for testing and deployment can be greatly reduced. Maintaining the same software environment from simulation to the production line is critical for a smooth rollout.

With MELSOFT Gemini, a 3D simulator from Mitsubishi Electric, viewing animation allows checking points such as fixture interference and robot arm motion. These are difficult to detect using logic simulators, and 3D simulators reduce the onsite work-hours during startup. Connecting the simulation capability of MELSOFT Gemini with the expansive connectivity of DeviceXPlorer OPC Server enables the seamless virtual simulation of a wide range of vendor devices coexisting on the production line, all in one simple installation.

In addition to MELSOFT Gemini, DeviceXPlorer OPC Server can communicate with other simulation software—including iCAD and Vmech—which support OPC interface. This versatile connectivity enables vendor-agnostic verification of control logic on both the simulator and machine sides.

Conclusion

By utilizing DeviceXPlorer OPC Server along with simulation software, system construction of factories and equipment lines can be simulated virtually without vendor lock-in.

By acting as a hub for different simulation software and virtual commissioning tools, the OPC industry standard for factory automation plays an important role in the acceleration of Digital Twins. As OPC UA Information Model (Companion Specification) continues to gain widespread adoption, the possibilities of Digital Twins will continue to expand.

Learn more about DeviceXPlorer OPC Server:

https://www.faweb.net/en/product/opc/

For a free trial via ICONICS:

https://iconics.com/en-us/Products/DeviceXPlorer-OPC-Server