SPONSORED BY: Software Toolbox

Introduction

The concept of logging data is nothing new, and digital transformation initiatives that are part of the world of Industry 4.0 are demanding more data than ever before, and OPC UA is a key enabling technology for accessing that data. Cloud machine learning and AI models demand more data, regulatory requirements in multiple industries require industry to prove compliance, and the reasons go on and on.

There is plenty of discussion around cleansing, aggregating, calculations and more advanced logging, but it’s often forgotten that many users just want to collect data from their OPC UA data sources and log it to SQL, or maybe to a cloud SQL database such as Azure. User applications have become more sophisticated and demand more, but their budgets may not match their ambitions.

Four Important Considerations

The users Software Toolbox works with have told us there are four key things they need in a solution that doesn’t break the bank to implement:

- Store & Forward

- Conditional / Trigger Based Logging

- Confirmed Logging

- Logging data from OPC UA Complex Data Structures

Let’s explore each of those and ways to address them.

1 – Store and Forward

Store & Forward is a term for technology that recognizes when non-local storage locations are not available, and locally stores data in a persistent data store, and forwards that data on to the remote location when it is available again. Store and forward is also very helpful when there are significant differences between the rate data is retrieved and the rate at which the storage destination can receive it, providing a buffer to ensure the data eventually gets there. There are many important details to consider when implementing store and forward. The most important thing is that the solution you choose supports it, but also:

- How much to store,

- How often do you write to the persistent data store,

- Performance impact of local logging,

- What criteria to use to determine whether the remote data store is inaccessible and when it is online again

We’ve discussed store and forward in more detail in a prior OPC Connect article, but the key is that your solution offers this without writing scripts and at prices that meet their budgets. In the resources section at the end of this article are links to learn more about a variety of solutions that support store & forward.

2 – Conditional / Trigger Based Logging

Users have told us they want to have logging be conditioned on more than just cyclical time based or data change conditions. Examples include but are not limited to logging based on conditions such as:

- Machine or batch start/stop signals available in controllers

- Schedule aligned to a work shift pattern

- Abnormal operating conditions indicated by points in a controller, or a complex logical combination of status bits or values in a controller

Users who still require logging to CSV text files have told us they want to not only start/stop logging based on conditions like above but also use them to trigger a new file being created.

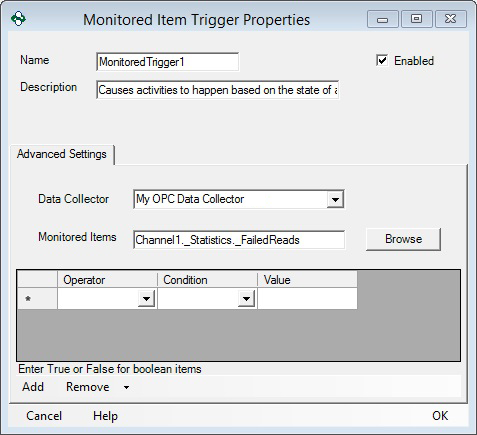

When considering solutions, users should seek applications that can accomplish these needs without writing scripts, or code, but rather can be enabled through a visual user interface like the one shown below:

3 – Confirmed Logging

Anyone can receive data, throw it over the wall and hope it is stored. Users have been clear, they have data that cannot be lost, especially if regulatory requirements are involved. Store and forward as we discussed is a key factor, but they also want further confirmation of storage before moving to the next block of data.

They often have logic in their PLCs/controllers that requires writing something back to confirm that the data has been received, only then will the controller logic fill up the data buffer again. They told us they need to, without writing code or scripting:

- Write confirmation to a point, based on their conditions, to any tag of any data type in their PLC/controller they can access using OPC

- Be able to combine confirmed logging with triggered/conditional logging and store and forward

- Monitor database connection state and write values to PLC/controller if it goes down/returns

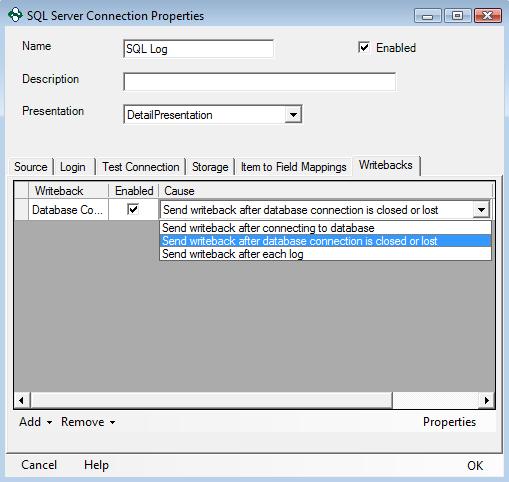

Like conditional logging, this needs to be done without scripting through a visual configuration user interface like the one shown below:

4 – Support for OPC UA in Devices & Complex Data Structures

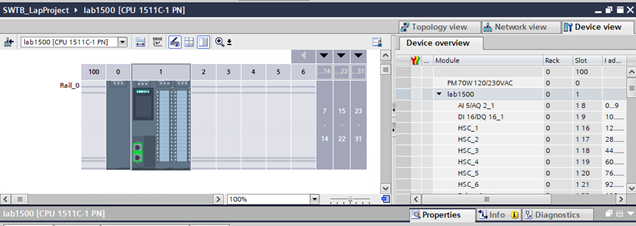

As users have adopted OPC UA, they are learning the power of OPC UA’s ability to present information in data structures, instead of just individual points like they did with OPC DA. Some PLCs support creation of native structures and present them through the built in OPC UA interface in the PLC as complex data structures, such as the Siemens S7-1500 shown below.

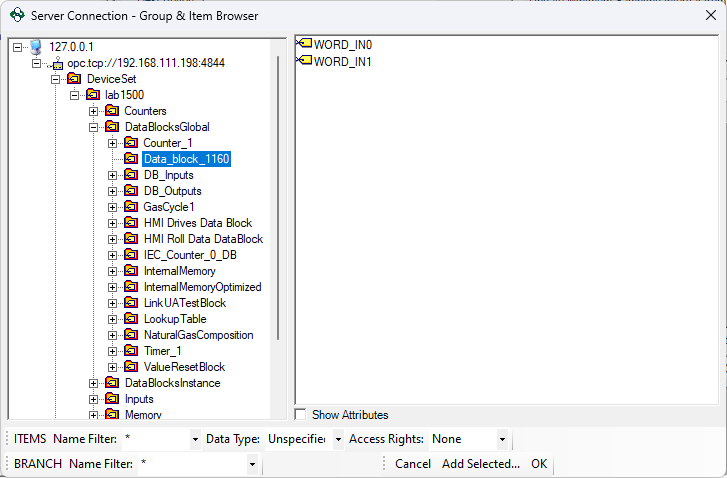

Just because a data logging solution supports OPC UA does not mean that the configuration supports browsing and choosing elements from complex data structures and logging the data elements like shown below.

Solutions

Software Toolbox has focused on providing visually configured, off-the-shelf software applications to industry since 1996, with a strong focus on rapid time-to-value solutions for all budgets.

We offer a variety of solutions for logging data. The OPC Data Logger, was originally created solely based on user demand and over the years has evolved based on their feedback, to support all of the functionality discussed in this article and log to text files, SQL, even cloud databases such as Azure SQL, at prices that won’t break the budget.

Use the links below to learn more about how OPC Data Logger meets these key requirements and other logging solutions from Software Toolbox.

Resources:

- Logging Solutions with Store & Forward

- Guide: Connecting to S7-1500 PLC via OPC UA & Logging Data

- Virtual Training: Conditional Logging

- Virtual Training: Confirmed Logging

- Video Guide: Logging OPC UA data to SQL Server in under 10 minutes

- OPC Data Logger Free Trial

- OPC Data Logger Training Videos

About Software Toolbox

Software Toolbox, founded in 1996 and a Charter Member of the OPC Foundation, was the world’s first industrial automation software company focused on software that leverages open standards for OT, IT, business and now cloud systems. Through our early leveraging the internet for global support reach we’ve built an installed base on every continent (yes even the South Pole Station!), they are known for their technical expertise across their variety of solutions that empowers success and reduces the risk of multi-vendor applications. Our raving fan users that trust our brand are a clear testament to the value we provide through the Software Toolbox way.