SPONSORED BY: Takebishi

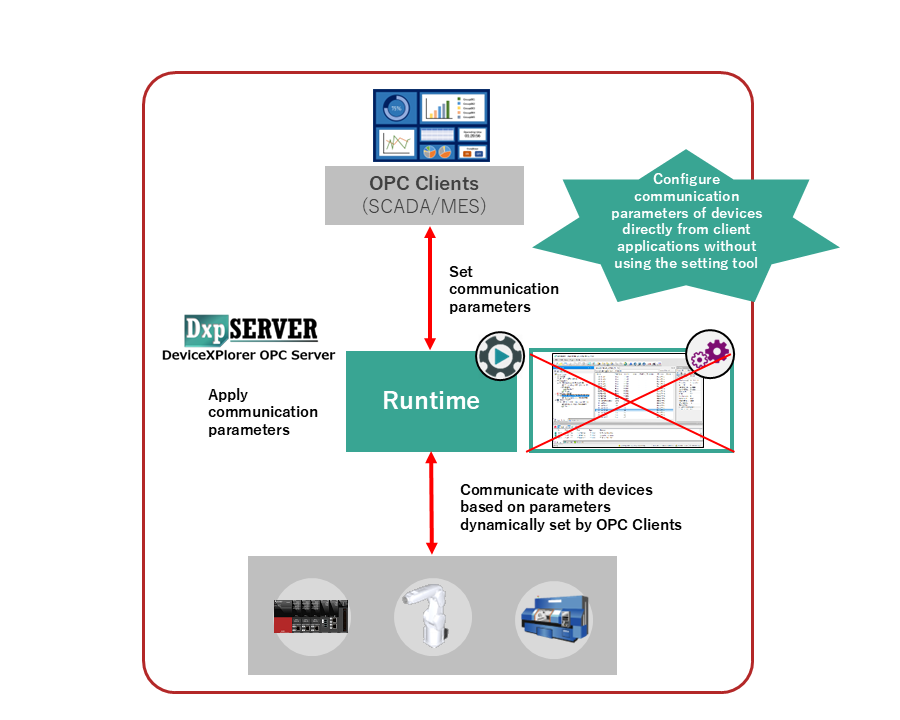

In the age of smart manufacturing and digital transformation, industrial systems must be more agile, integrated, and responsive than ever before. Takebishi’s latest release of DeviceXPlorer OPC Server v7.4.2 introduces a powerful new capability that meets these demands head-on: external configuration capability. This feature allows external applications to dynamically create, delete, and modify communication parameters and tag configurations for devices – ushering in a new era of Dynamic automation.

Engineering Efficiency with External Configuration

DeviceXPlorer OPC Server has introduced new system tags that expose internal device communication settings to external applications. Previously, configuring DeviceXPlorer OPC Server required manual input through the dedicated setting tool. With this update, external systems – such as SCADA (Supervisory Control and Data Acquisition) platforms, MES (Manufacturing Execution System) software, or custom applications – can now handle the configuration of DeviceXPlorer OPC Server such as:

- Create, update, and delete tags

- Create, update, and delete communication parameters with devices

- Backup and update the configuration file

This shift from manual to dynamic configuration, dramatically improves operational efficiency. Engineers can now automate setup processes, synchronize configurations across multiple systems, and respond to changes in real time – all without using the dedicated setting tool.

To illustrate, imagine a production line where new devices are added regularly. Instead of manually configuring each device’s tags with the dedicated setting tool, the configuration for the new devices can be quickly integrated from external applications. Configuration of multiple devices, using various external automation technologies, ensures consistency across devices, a must for scalable systems.

Read the full article on the Takebishi FAWEB site to learn more about dynamic configuration for complex data systems.