OPC in the production of hydrogen and electricity at zero emissions thanks to aluminum combustion

PROGEA is one of the companies that participated in the technology innovation project called Enerclean, coordinated by the Department of Science and Engineering, University of Modena and Reggio.

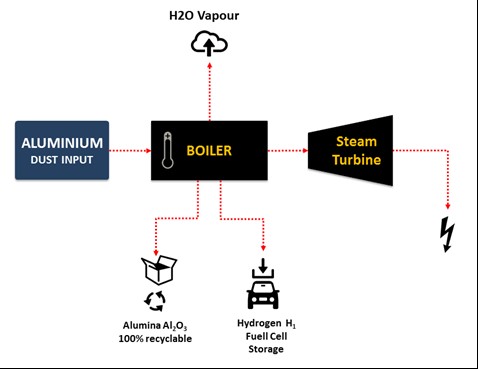

The project involves the production of clean energy and hydrogen through the natural process of combustion of aluminum powder on contact with water. The goal is to get a high efficiency energy system with near zero environmental impact.

According to this project, using raw aluminum and water to produce steam which drives a turbine, the waste products are hydrogen and alumina. The former is stored for stations of vehicles powered by hydrogen (fuel cells), and the latter is fully recyclable to produce new aluminum.

The project involves the construction of an energy system based on the use of the products and by-products of the combustion of a solid fuel in water-saturated environment that is able to achieve integrated and simultaneous generation of four secondary energy sources, giving rise to an application classified as Hydrogen and Steam Combined Heat Power (CHHSP) completely.

The project, while still experimental, gave the desired results, and the system prototype was successfully completed. The group of participating companies, coordinated by Prof. Milani, received a specific development objective, skills, know-how and market technologies. The main components of the system are:

The project, while still experimental, gave the desired results, and the system prototype was successfully completed. The group of participating companies, coordinated by Prof. Milani, received a specific development objective, skills, know-how and market technologies. The main components of the system are:

- a milling machine that provides continuous power cycle, producing Aluminum powder

- special cutters that produce the fine dust needed to fuel the combustion chamber

- pressure injection into the water

- the combustion

- the steam needed to power a 4 MW turbine

The whole system of boiler management process is automated by a PLC. Finally, there is the waste recovery system, consisting of a hydrogen storage system for fuel cells, and Alumina powder, recovered for aluminum producers.

Atmospheric emissions are zero because the process produces only steam.

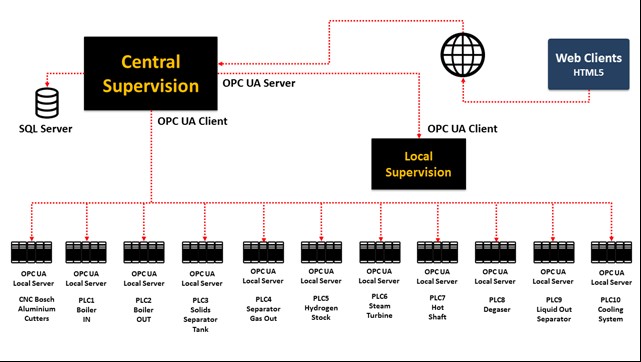

All subsystems are connected to each other through standard OPC UA communication. Only OPC UA was able to guarantee the necessary technology in a new system like the one created, and able to be the “standard” in different systems as part of a single process.

All subsystems are connected to each other through standard OPC UA communication. Only OPC UA was able to guarantee the necessary technology in a new system like the one created, and able to be the “standard” in different systems as part of a single process.

In fact, it was necessary that the various partners used components that could communicate at all levels with maximum transparency, with maximum performance and maximum safety. For this reason, the choice fell to OPC UA technology.

The Department needed a modern supervisory system, OPC UA based, and able to satisfy any specific requirement, each time adapting to the changes that an experimental project.

They directly involved Progea and NExT, a next-generation platform based on OPC UA.

The management system allows local and remote control of the production process of aluminum powder, storage, combustion, turbine and alternator, hydrogen storage and alumina products.

The supervisor then provides a redundant server for data acquisition from three different subsystems:

- Powder feed system

- Boiler and turbine

- Hydrogen Storage and Alumina Recovery

All systems were made by their respective companies and project partners who used their know-how to achieve the goal. Control systems were adopted from BOSCH Rexroth for the powders and power cutters and Beckhoff for the boiler, turbine, and storage and retrieval systems, for a total of 10 connected PLCs.

All systems were made by their respective companies and project partners who used their know-how to achieve the goal. Control systems were adopted from BOSCH Rexroth for the powders and power cutters and Beckhoff for the boiler, turbine, and storage and retrieval systems, for a total of 10 connected PLCs.

All subsystems are communicating through the centralized supervision system, and all are connected via OPC UA.

CNC Milling Dust Control

- PLC1 = boiler inputs

- PLC2 = boiler outputs

- PLC3 = cistern and solids separator

- PLC4 = exit gas separator

- PLC 5 = hydrogen storage

- PLC6 = turbine contour

- PLC7 = hot pit contour

- PLC8 = outline getter

- PLC9 = separator, liquid outlet

- PLC10 = cooling system

The Central attendant is based on a client/server architecture. NExT allows connectivity between supervision and local OPC servers, integrated directly into the PLCs.

The supervisor then acquires, as a central server in real time, all functional parameters, representing the subsystems through the numerous pages that represent the synoptic system. The central attendant acquires more than 8,000 analog variables (tags), distributed in various systems of local control. In addition, there are about 2,000 digital alarms that provide detailed system diagnostics.

Locally there is a client station supervisor, then as OPC UA client connected to the central server. All communication in the field takes place solely via OPC UA supported by NExT.

Essential for the development of the experimental system was the monitoring, recording and analysis of all sensitive data, such as pressure, flow rates, temperatures, humidity levels, etc. They are recorded in a SQL Server database system allowing accurate analysis of the functional parameters necessary for the engineers of the Department of Science and Engineering.

In addition, the central supervision system is web-based, thereby connecting remote stations via HTML5, to the system with full safety.

“We needed a system that could connect the owner’s data at any level,” says prof. Milani. “That’s why we focused on the OPC UA standard, able to be managed either by control devices or telemetry systems, and in the future for any higher level integrated systems, such as SAP systems used by the operators. ”

The prototype system was put into operation, and the first results were very positive.  Obviously the system must be perfected to be industrialized, but the conceptual idea should offer good prospects for development. Producing thermoelectric energy and hydrogen, so cleanly might be the way of the future.

Obviously the system must be perfected to be industrialized, but the conceptual idea should offer good prospects for development. Producing thermoelectric energy and hydrogen, so cleanly might be the way of the future.

The combustion system is based on aluminum and water, renewable fuels and products with no risk (for example, compared to traditional systems  based on gas, petroleum, or uranium). The process is also nonpolluting because it does not produces CO2 (zero emission) and the waste products are: hydrogen and alumina, both totally recovered for industrial uses. The hydrogen stored is expected to supply fuel cells for cars, while alumina is a mineral often used in industry, and currently produced for the market using the so-called “Bayer method”.

based on gas, petroleum, or uranium). The process is also nonpolluting because it does not produces CO2 (zero emission) and the waste products are: hydrogen and alumina, both totally recovered for industrial uses. The hydrogen stored is expected to supply fuel cells for cars, while alumina is a mineral often used in industry, and currently produced for the market using the so-called “Bayer method”.

Currently the project is still in the experimental stage, but the conditions for its industrialization are very good.

–Ing. Daniele Suffritti, Consultant