by Nathan Pocock, Director of Technology and Compliance, OPC Foundation

It seems as though everyone has now heard of the Internet of Things (IoT) and Industry 4.0 and the opportunities ahead. But are you prepared to benefit from this next technological leap while maximizing your opportunity with minimal risk and cost?

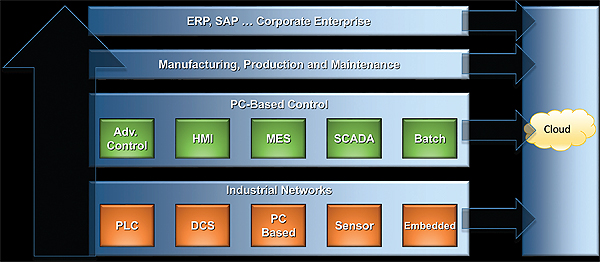

Since the 1990s, technology development has generally focused on the PC platform. The past few years, the focus was on mobile platforms. Today’s focus is two-fold: small-scale devices and large-scale cloud infrastructures and getting them, and everything in-between, to work seamlessly together.

What is driving this change? Data. Successful businesses are focused on maximizing their efficiency and reducing costs. This means that important business decisions need to be made much faster than ever before, with minimum investment, and maximum effect. Is this possible? It’s always been “possible,” it just wasn’t cost effective or easy. With the IoT, the claim is that now it will be both.

New products are available that are intelligent and provide contextual information to enable rapid decision making (human or automated), and to scale to the needs of the enterprise.

OPC Unified Architecture harmonizes many existing OPC standards (Data Access, Historical Data, Alarms and Conditions, Programs, Security and more) into one cohesive standard.

The OPC Unified Architecture (UA)

One key to success is adopting open standards such as OPC UA, a platform-independent technology that assures interoperability.

Initially targeting the Industrial Automation industry, OPC technology emerged in the mid 90s and was based on Microsoft technologies, but was revamped in the early 2000s to be a future facing, platform independent technology. This standard harmonizes many existing OPC standards (Data Access, Historical Data, Alarms and Conditions, Programs, Security) into one cohesive standard.

The number of OPC products available in the marketplace easily exceeds 10,000. The exact number is unknown, and the number of installations is estimated to be in the tens of millions. OPC is used in commercial products and countless internal-only systems. An abundance of applications, such as visualization, data-logging, alert notifications, or other business-intelligence applications, can immediately integrate with your products, making a strong case for adopting this standard.

OPC technology is platform independent and already implemented on Windows, Linux/*nix, Apple and Android. It is also embedded in controllers, such as PLCs and Raspberry PI, and a multitude of other small-scale circuitry.

The number of PC-based applications is massive, but we’re also seeing OPC enabled at the controller level, from the DCS and PLC, down to the microchip. Companies such as Beckhoff, GE, Honeywell, Rockwell, Siemens and others, all have OPC UA enabled hardware.

This standard has spread beyond the industrial automation industry that it has served so well for the last two decades, and is now deeply rooted in oil and gas, building automation, and energy, with more industry horizontals and verticals following.

What does OPC do?

Why choose OPC technology to share data? Because that’s what it is designed to do. There are five core features of this standard:

- Browsing: the ability to locate OPC systems on a network and connect to them and visually browse the availability of data using a file/folder methodology

- Reading: data-points or objects and so on

- Writing: to one or more data-points, or entire objects

- Subscriptions: receiving update notifications for when data/information changes

- Eventing: to give meaningful alert notifications

These capabilities provide the entire infrastructure necessary for OPC products to share data/information of any kind with one another.

The majority of products implement three key parts of the OPC standard:

- Data access, for real-time data sharing

- Historical data/events, for analytics and reporting of data and events stored in a database/historian

- Alarms and conditions, for alarm events that notify when alarm-triggers are hit, such as a temperature reaching a Low or High-High set-point, and so on.

Each of these Profiles serves a purpose; you pick and choose the feature or function you need within your product(s).

This standard is successful because of its plug-n-play design. An OPC Client interacts with an OPC Server.

The OPC Foundation Compliance Working Group provides members with Compliance Test Tools (CTTs) for automated compliance testing, test-case specifications and interoperability workshops for face-to-face testing between different vendors and their products. The OPC Certification Test Lab conducts vigorous testing to validate a product is interoperable, compliant, robust and efficient with resources. End-users are increasingly demanding certified products because it reduces their risk and increases the overall reliability of their infrastructure.

Reprinted with permission from November 10, 2014 issue of Design World.