As I’m sure you’re probably aware, OPC has been around as an industry standard since 1996. If you’ve been working in the space very long, you have probably heard all the different acronyms thrown around. If you’re new, well there are different specifications in the OPC software interoperability standards that are used to meet different information integration needs (i.e. OPC DA, OPC A&E, OPC HDA, and the latest, OPC UA).

In industrial operations, it’s generally impossible to just change things haphazardly. There’s too much risk, downtime cost, and planning involved to change the whole operations and plant control system at one time. The natural state of things is that we find a range of ages and levels of software, standards and systems that need to work together harmoniously. The challenge becomes how to insure those systems can interoperate with newer systems to allow continuous improvement, while not breaking anything.

In the past when someone said they were using OPC with their HMI, they typically meant OPC DA and the use case was gathering data from a device such as a PLC, or other controller with the HMI talking to an OPC Server. OPC DA is still more widely used than the other OPC specifications. That won’t be true for too much longer, thanks to OPC UA. OPC UA was first released about 10 years ago. As with anything in industrial operations, users were slow to adopt the new technology.

While OPC DA still has a large installed base, many companies are making the change to OPC UA for increased security and improved ease of use. Many companies find themselves adding new software with OPC UA capabilities while still having to support legacy systems that only support OPC DA.

Converting between OPC DA and OPC UA

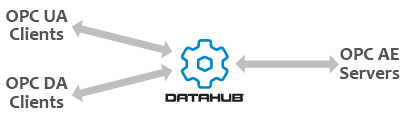

There are two use cases you should be aware of if you have a mix of OPC DA and UA clients and servers in your company. If you’re asking yourself “What is an OPC Client and Server?” click here.

- OPC UA Server to OPC DA Client

- Example: You have a newer device or system that has an OPC UA server to provide data, but your HMI/SCADA/MES doesn’t yet support or implement OPC UA client capability to obtain the data, and only implements OPC DA client.

- OPC DA Server to OPC UA Client

- Example: You have an HMI/SCADA/MES that supports OPC UA client and it needs to get data from an older system with an OPC server available to provide the data, but the OPC server doesn’t support OPC UA or you aren’t able to upgrade it to a newer version that does support OPC UA.

Many of our users have chosen the DataHub OPC Gateway software to solve this conversion challenge since it supports both OPC DA and OPC UA in a single software package. The DataHub can connect any OPC DA server or client to any OPC UA server or client in just a few steps and typically doesn’t require much more than 10-15 minutes at the most for the majority of client or server connections.

Using the DataHub OPC Gateway you can:

- Add OPC UA to existing plant systems that currently use OPC DA, which can be especially useful for making secure remote connections easily between machines and networks.

- Enable an incremental transition from DA to UA by allowing existing OPC DA only solutions to continue functioning seamlessly with new OPC UA solutions.

- Interconnect OPC products from different vendors supporting either OPC DA or UA, thus making your overall solution vendor-agnostic and allowing you to choose the best components available regardless of vendor.

- Aggregate multiple OPC DA Server sources for access as one OPC UA server by your OPC UA clients (or vice versa), whether for technical reasons such as a particular client application only supporting a single connection or simply because it’s just easier to have one place to go for your data.

Converting OPC A&E to OPC DA or OPC UA

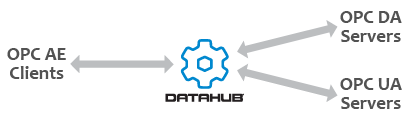

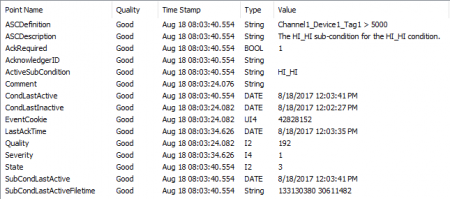

The 3rd OPC specification that the DataHub supports is OPC A&E. Typically, OPC A&E data can only be served to other OPC A&E Clients. That’s because OPC A&E data points are more complex, having a single OPC A&E data point that contains information about the alarm limits, if the alarm is in condition, when it was last in condition, when it was acknowledged, etc. What if you want to get this A&E information into your HMI/SCADA applications, but they don’t support OPC A&E? That’s where the DataHub can help.

DataHub has the ability to convert the multiple properties of an OPC A&E data point into individual data points. Since each of those alarm properties is now an individual data point, the DataHub can serve up this data to any OPC DA or OPC UA Client.

While it’s also possible to access OPC DA and OPC UA servers from OPC A&E clients using DataHub, most OPC A&E clients will also support either OPC DA, OPC UA or both for accessing non-A&E data sources, so that use case is less common. However, it is certainly possible if you happen to have a client application that only supports OPC A&E.

In short, the DataHub supports more than just OPC Data Access to enable flexibility and interoperability between your disparate OPC systems. Because of that, it can act as an OPC protocol converter to convert:

- OPC DA Server to OPC UA Client

- OPC UA Server to OPC DA Client

- OPC A&E Server to OPC DA Client

- OPC A&E Server to OPC UA Client

The DataHub enables you to take advantage of the latest OPC technology without the cost and effort of retrofitting your entire control system, allowing you to continue leveraging your previous investments in OPC Classic solutions.

Additionally, the DataHub offers a wide range of functionality for accomplishing an extremely diverse set of challenges many users, like you, may experience on different integration projects. Functionality including bridging data between different sources, sending email or SMS text reports or notifications, acting as a gateway solution between different types of OPC and other data sources and more.

As always, you can email us at support@softwaretoolbox.com with your questions and subscribe to our blog for more OPC and automation related topics and how-tos. If you’re not familiar with Cogent DataHub but have similar needs to the use cases presented in this article, you can try DataHub for free. Click to Download Your Free Trial. And if you’d like to test DataHub with your system for more than one hour at a time, click here to request your free extended trial license.