With umati, the machine tool industry, for the first time, has a vendor-neutral communication interface specification. In addition, because OPC UA is its underlying technology, umati will be capable of being deployed in future end-to-end solutions spanning entire process chains in the manufacturing industry.

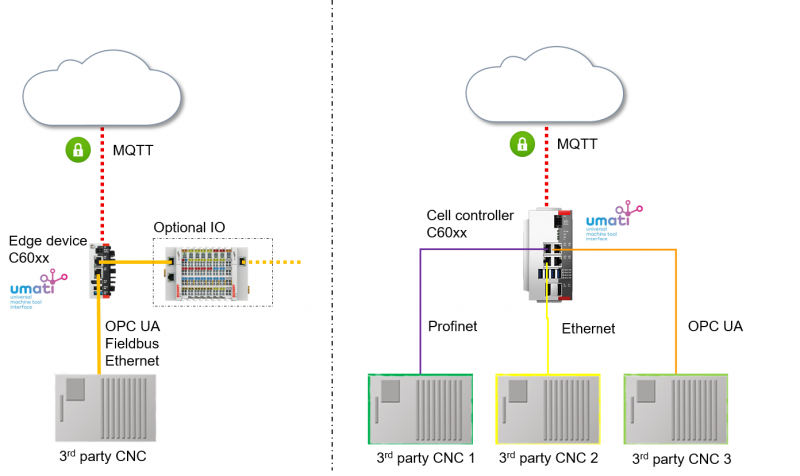

When combined with the ultra-compact C6015 Industrial PC and TwinCAT OPC UA from Beckhoff, umati offers an ideal solution, not just for networking new-build manufacturing plants but also, crucially, for retrofits to existing installations. This combination is capable of meeting the requirements of today’s Industrie 4.0 solutions with just minimal effort. Beckhoff is currently working on implementing PC-based umati solutions using OPC UA products that are already available. Its focus here is both on creating seamless connectivity between TwinCAT NC I/CNC and the umati information model and, in particular, on integrating third-party controllers in edge scenarios.

In light of these efforts, Beckhoff will be showing a presentation on umati at its own booth at EMO (D32 in Hall 9) as well as taking part in a live demo instigated by VDW, which will incorporate multiple customer machines connected over umati. The latter will be a showcase example of the advantages of the ultra-compact C6015 IPC as well as the overall openness of the Beckhoff technology: For the majority of the machine tools running in the live demo, the C6015 will serve as an easy-to-deploy, space-saving IoT gateway that adds IoT capabilities to the machines, regardless of the types of CNC they use. In addition to data provisioning with umati, Beckhoff will also be focusing at EMO on data processing by OPC UA clients as a foundation for PC-based aggregation solutions and cell controllers.