PLCopen OPC-UA Function Blocks modelling MDIS Information

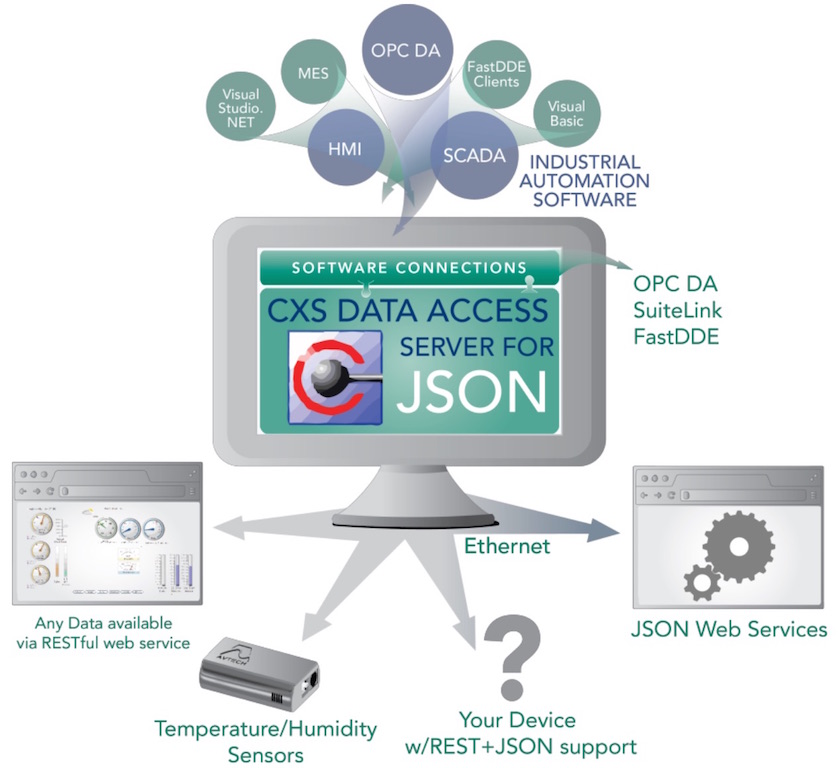

At its core, OPC UA combines a robust, secure communication protocol with a flexible information modeling framework. A challenge for the PLC vendor deploying OPC UA in embedded devices is how to represent different customers’ information modeling requirements in a common way.