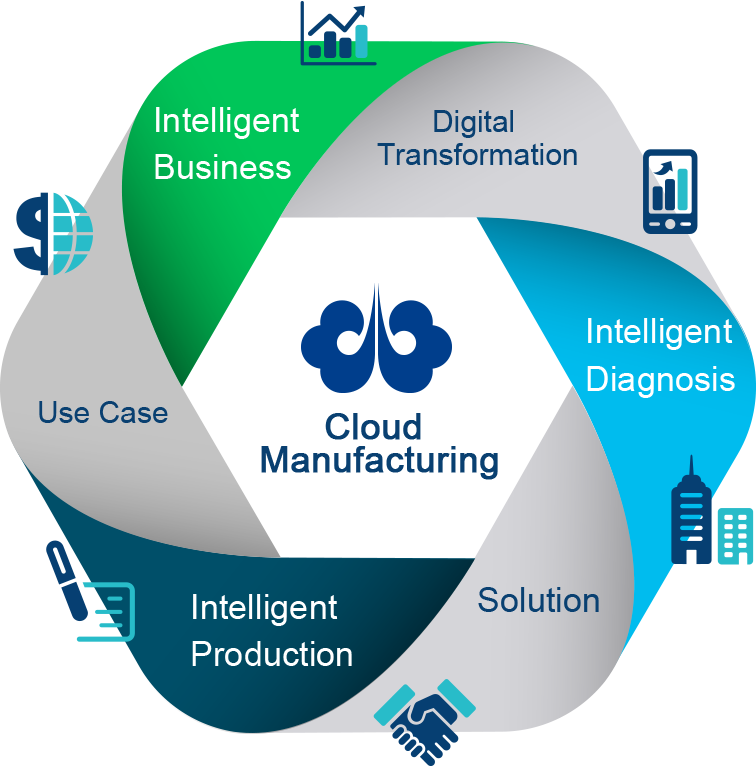

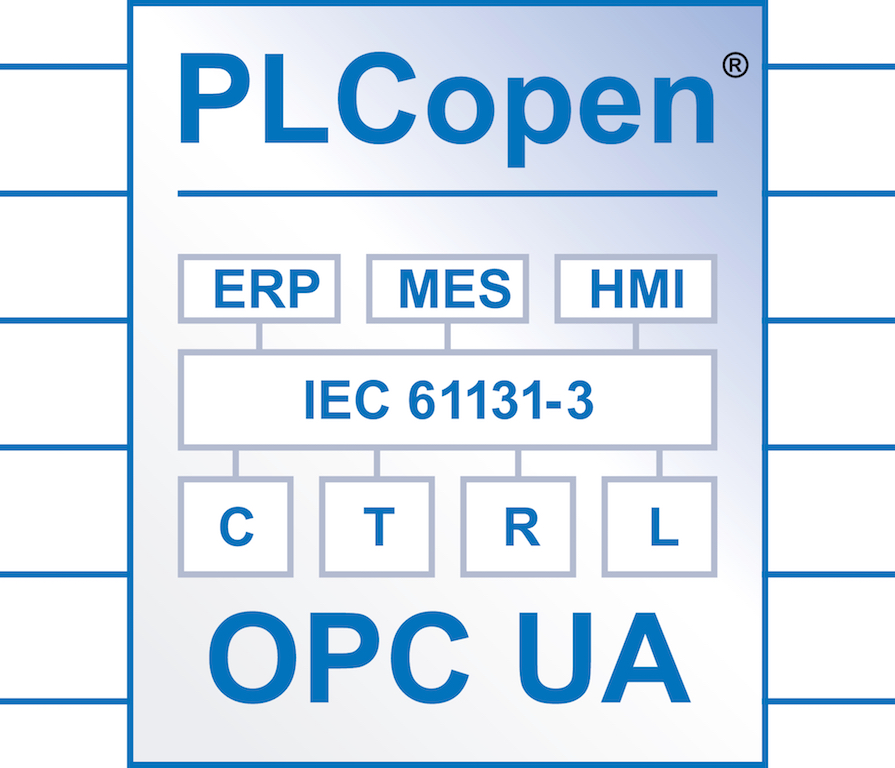

LG CNS has been providing factory operation consulting and services for various industries including electric / electronic, semiconductor, automobile, medical, pharmaceutical, shipbuilding / heavy industry, construction / machinery, health, clothing, and logistics for the past 20 years. With OPC UA, LG CNS can develop products that are ultimately going to be deployed to extend across facility control and the MES domain via a standardized and consistent approach for smart factories. It will be used in the integrated engineering business by providing device modeling and meta information exchange function on the server side, as well as basic data collection, monitoring, analysis and control functions on the client side.