Benninger Automation forms part of the Swiss Benninger Group which has been the textile industry‘s leading partner across the globe for more than one hundred and fifty years. Benninger develops and manufactures textile finishing and cord production ranges as well as providing complete system solutions. The vast knowledge of Benninger in the field of controls and automation is based on many years of experience with machines and ranges, also in other industries. The German subsidiary uses the company’s long-standing experience in automation and develops complex designs for both control systems and mechatronic applications. These are implemented as wide-ranging projects that include consulting and training, hardware and software development, switchgear construction, commissioning worldwide and after sales services.

Benninger Automation forms part of the Swiss Benninger Group which has been the textile industry‘s leading partner across the globe for more than one hundred and fifty years. Benninger develops and manufactures textile finishing and cord production ranges as well as providing complete system solutions. The vast knowledge of Benninger in the field of controls and automation is based on many years of experience with machines and ranges, also in other industries. The German subsidiary uses the company’s long-standing experience in automation and develops complex designs for both control systems and mechatronic applications. These are implemented as wide-ranging projects that include consulting and training, hardware and software development, switchgear construction, commissioning worldwide and after sales services.

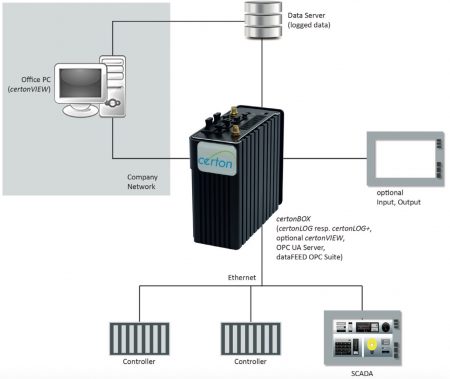

Supplementing its customer-specific development work, Benninger Automation also deploys prefabricated components in its projects. These components cover frequently required functions and are also offered as products. Benninger Automation offers the modular certon product for the collection, logging, display, and forwarding of data from control systems or SCADA systems. The product can be used to record incoming data such as actual values and setpoints for temperature and pressure, flow rates and meters, messages, recipe values, and user input for a specific period of time (e.g. a day or a shift) or for a production unit (such as a batch or a lot, for example). All of these data items are stored together with the date, time of day, a comparison of new and previous values, and a code representing the currently logged-in user.

Supplementing its customer-specific development work, Benninger Automation also deploys prefabricated components in its projects. These components cover frequently required functions and are also offered as products. Benninger Automation offers the modular certon product for the collection, logging, display, and forwarding of data from control systems or SCADA systems. The product can be used to record incoming data such as actual values and setpoints for temperature and pressure, flow rates and meters, messages, recipe values, and user input for a specific period of time (e.g. a day or a shift) or for a production unit (such as a batch or a lot, for example). All of these data items are stored together with the date, time of day, a comparison of new and previous values, and a code representing the currently logged-in user.

While developing “certon”, Benninger Automation has focused closely on usability features. As one example, no programming knowledge is required to configure certon for the local data logging environment.

The data logging itself is handled by the certonLOG module. This software is installed on a host PC and collects data from the connected sources via an OPC UA client. The mechanisms used in the OPC UA communication standard not only safeguard the actual exchange of data but also ensure that it is transferred securely.