Don’t Get Left Behind! OPC Accelerating Transformation!

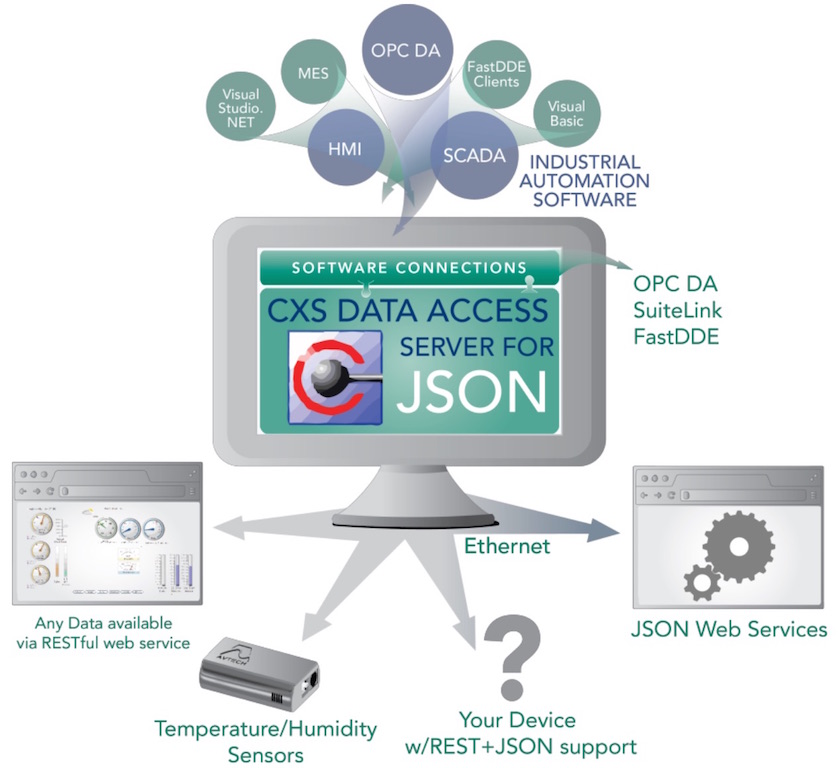

While IoT standards and interoperability are likely to be subjects of ongoing debate and discussion over the next few years, there are already well-established standards in industrial and manufacturing environments that can accelerate the shift to outcome-based models. In fact, OPC Unified Architecture is a platform independent service oriented architecture that provides standard models for secure and reliable information exchange in industrial automation across a range of manufacturing and resource industries.