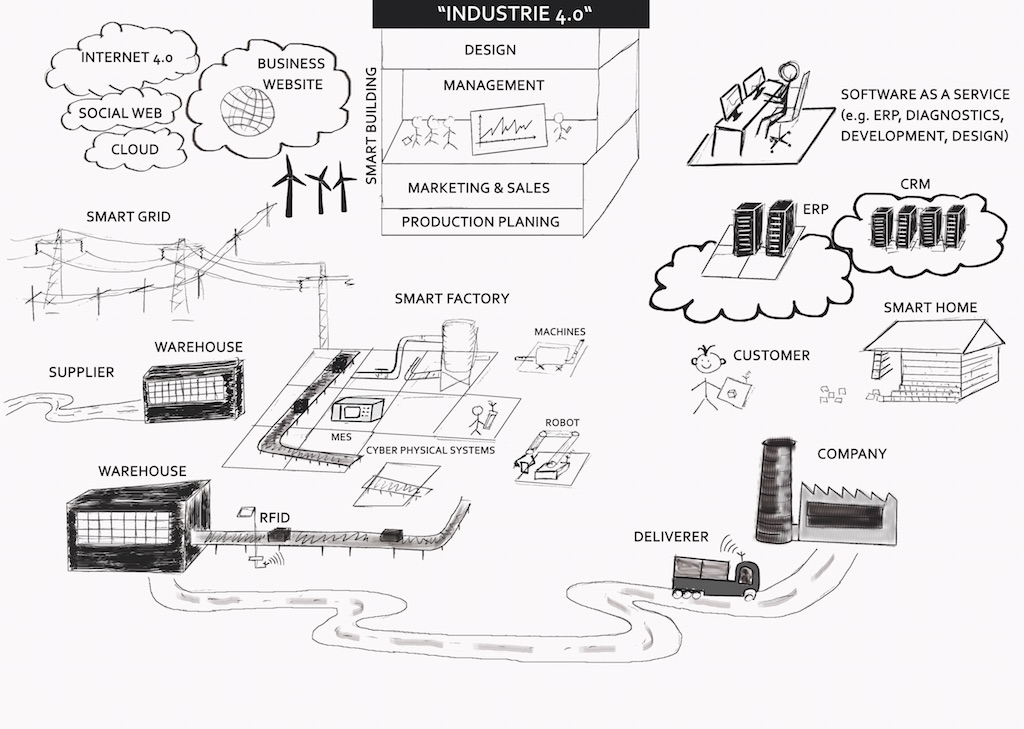

OPC UA in the Reference Architecture Model RAMI 4.0

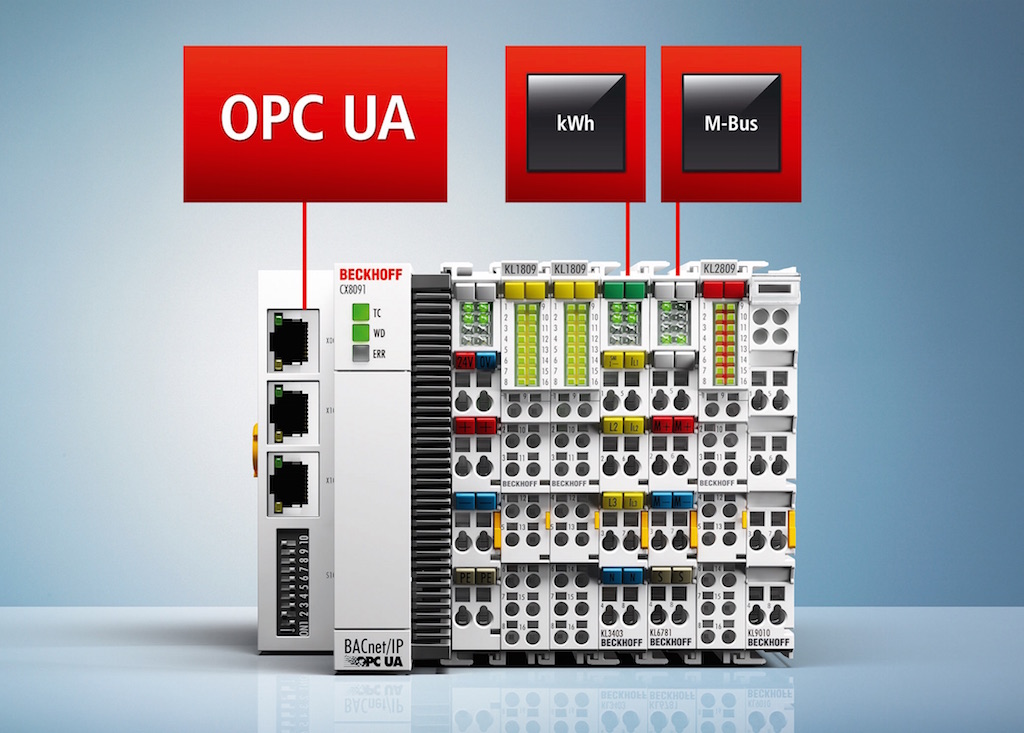

The German Industrie 4.0 platform, consisting of ZVEI, VDMA, and BITKOM, has jointly reached important milestones in the standardization of Industrie 4.0. The first version of a reference architecture model for Industrie 4.0 (RAMI 4.0) which precisely describes Industrie 4.0-compliant production equipment, has been developed. OPC UA is listed as the one and only recommendation for realizing the ‘communication’ layer.