SPONSORED BY: BECKHOFF

Universal human-machine interface enables custom controls for flexible expansion

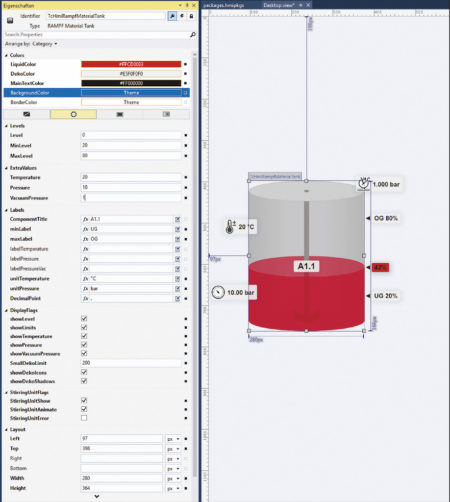

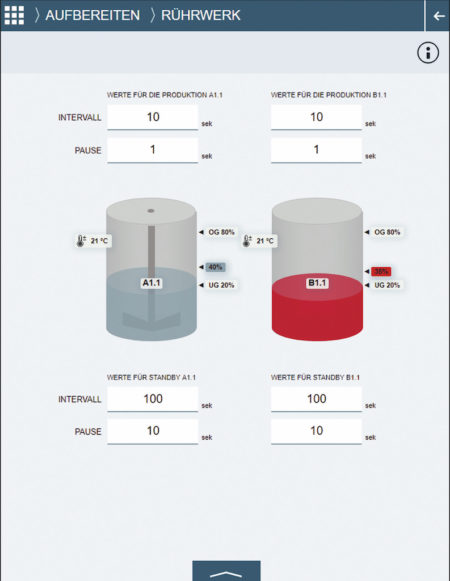

RAMPF Production Systems GmbH & Co. KG, based in Zimmern ob Rottweil, Germany, relies extensively on hardware and software from Beckhoff in its high-performance dispensing applications. These systems have a particular focus on TwinCAT HMI, which served as the basis for developing a new, universal operator interface: It allowed the necessary customization work to be completed with relatively little effort using a combination of standard graphical controls and specially created design elements produced with the support of a multimedia company, Feldmann media group AG, in Nuremberg.

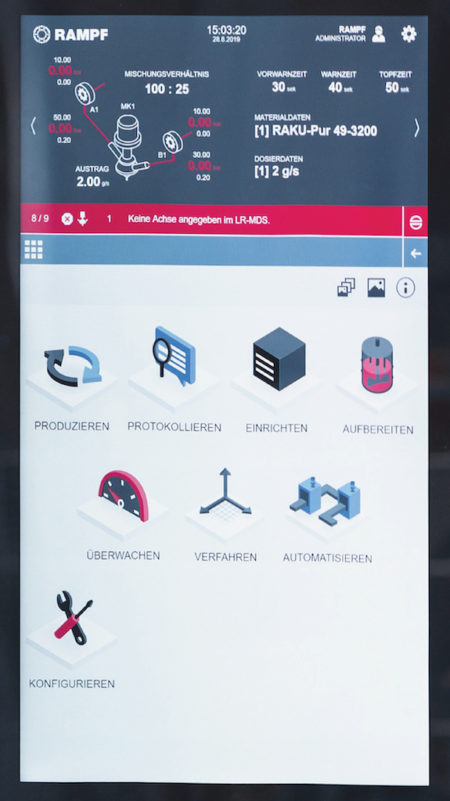

Development of the new HMI was initiated in connection with the DR-CNC dispensing robot, which is optionally available with a comprehensive control technology package from Beckhoff. The automation functionality, CNC chassis motion and precision dispensing technology are all implemented using PC-based control. The system incorporates Beckhoff drive technology, a C6930 control cabinet IPC, a CP2918 multi-touch Control Panel, TwinCAT PLC, NC I, OPC UA and, of course, TwinCAT HMI software. Says Hartmut Storz, Managing Director at RAMPF Production Systems: “The new operator interface built on TwinCAT HMI provides us with a universal platform that will become our new standard. The open communication via OPC UA ensures that not just Beckhoff controllers but third-party systems can be used with it as well.” The fundamental goals behind the project, he explains, were to create a unified operator interface capable of integrating with control systems from different vendors and to implement state-of-the-art technology in anticipation of increasing digitalization. Other important factors were the ability to scale to different display formats, to support smart devices through HTML5 and to enable full touch-based operation.

RAMPF had high requirements when it came to the new HMI’s design – including that it could be used completely intuitively without prior training, and that it had to have a modern look and feel. There were other considerations, too, tied to machine functionality. For instance, it had to specifically support CNC operation, which Beckhoff helped simplify. Scalability was also important – to allow the HMI to switch from the standard display size of 18.5 inches to 22 inches, for instance, for use at industry shows. From a technical standpoint, key priorities were to make the HMI quick and easy to set up, yet sufficiently flexible to permit changes and adjustments where necessary; it also had to be fast enough to enable smooth transitions between pages.

Advanced, Unified HMI Projects with an Eye to the Future

The new operator interface is forward-looking in that it will also work with mobile devices like smartphones and tablets if required. At the same time, it paves the way to greater digitalization in production, which is still in its infancy. For Storz, the potential of digital technologies to deliver greater efficiency, speed and reliability in manufacturing processes is still far from fully understood, let alone exhausted: “It’s with this in mind that RAMPF Production Systems developed the new operator interface for its dispensing equipment and robots. This easy-to-use tool is central to manufacturing companies’ digital strategies.” RAMPF’s human-machine interface, he continues, can also serve as a basis for developing customer-specific HMI elements, because its modular design significantly reduces the time and effort for programmers at end-user companies.

Unifying its various HMI projects creates valuable advantages for RAMPF, as Storz explains: “Given our range of equipment types and customer requirements, we often use different controllers, for instance, or hardware components such as operating panels. Until now, that sometimes involved having to adapt entire HMI projects, or even start completely from scratch. As a result, we have a number of separate basic HMI projects that would need to be adapted or modified as systems evolve, which in turn would require a lot of maintenance. The HTML5-based TwinCAT HMI and OPC UA eliminate this problem: They allow any HMI computer to be used, provided it can run a browser.”