SPONSORED BY: UTTHUNGA

To achieve the objectives of Industry 4.0, embracing digital transformation has become imperative for companies to follow processes, enhance efficiency, and drive innovation. This article covers case studies on how companies from two industries, steel and oil & gas, started their digital journey from the ground up. Utthunga’s solutions helped its client achieve streamlined data management, device communication, and sensor-to-cloud process automation by addressing the challenges arising from the outdated setup.

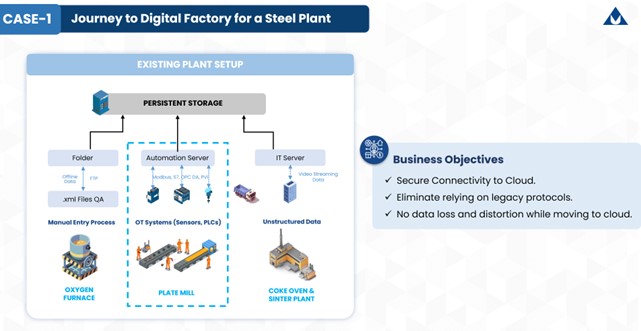

Case 1: Journey to Digital Factory for a Reputed Steel Plant

The Challenges

The steel plant’s existing setup posed several hurdles that affected its operational efficiency and agility. The first challenge revolved around multiple manual data updates that were time-consuming and labor-intensive.

Manual entries of enormous XML and video clips from various sources, such as the oxygen furnaces, coke ovens, and sinter plants, were prone to errors – causing cascading effects. Moreover, it also resulted in weak data analysis and delayed decision-making that were critical to the business.

The second challenge was consolidating real-time data from various sensors and programmable logic controllers (PLCs). Clusters of devices operating on different communications like Modbus, S7, and PVI (Process Visualization Interface) lead to inefficient data integration, interoperability, data management, and optimization. Consequently, the plant needed help to harness its infrastructure’s full potential to improve operations and drive data-driven decision-making.

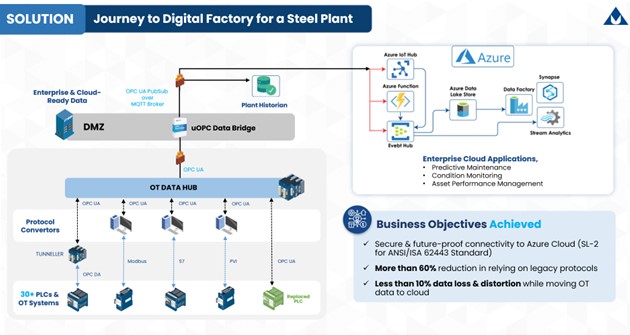

Utthunga’s Solution

To integrate the data from 30+ PLCs seamlessly with Azure Cloud, Utthunga suggested suitable Protocol Converters and Aggregators that would convert the protocol supported by the PLC to OPC-UA. In some cases, the legacy PLCs were replaced with new ones that supported OPC-UA natively. All the Protocol Converters were aggregated to a single OT Data Hub and then connected to the uOPC DataBridge to secure data passage across the DMZ. The Azure IoT Hub could access the data via an MQTT Broker in OPC PubSub format.

Utthunga’s well-researched solutions had an immediate impact on the Steel Plant,

- Secure & Future-Proof connectivity to Azure Cloud (SL-2 for ANSI/ISA 62444 Standard)

- More than 60% reduction in relying on legacy protocols for OT data

- Minimal data loss and distortion while moving OT data to the cloud

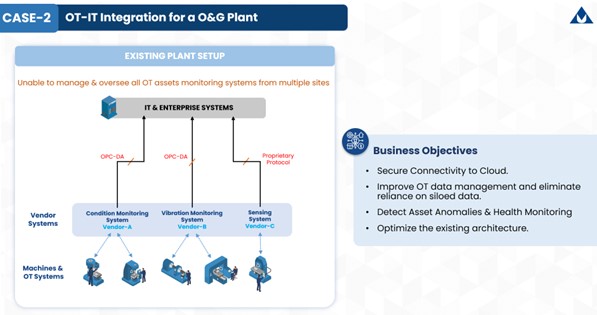

Case 2: OT-IT Integration for an Oil & Gas (O&G) Plant

The Challenges

The client’s (O&G) site was a complex infrastructure of various devices, sensors, and programmable logic controllers (PLCs). With a wide range of equipment across hazardous locations operating on different communication protocols, efficient operations, and maintenance, they posed practical day-to-day challenges.

Moreover, devices from different vendors amplified the complexity. With each vendor supporting specific technologies and communication protocols, the lack of unified device integration and data analysis created nightmares for achieving the much-needed IT-OT synergy.

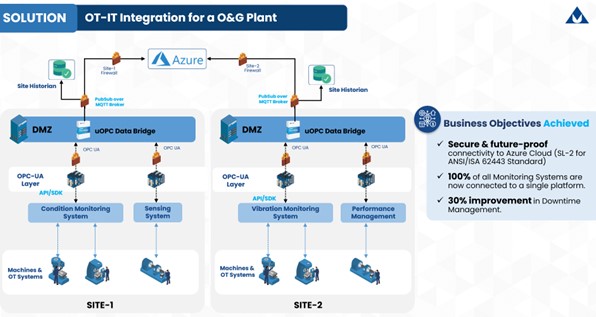

Utthunga’s Solution

Utthunga created an OPC-UA layer to collect the data from different vendors’ machines. The primary idea was to connect with the APIs/SDKs of the respective vendors’ Systems and expose the data to the North-Side via OPC-UA. The uOPC DataBridge was then used to securely pass the data across the DMZ. Utthunga deployed suitable site-based Firewalls in each site to ensure the secure passage of data via the MQTT Broker to the Azure IoT Hub for further analysis. This solution resulted in the following:

- 100% connectivity to all Machine Monitoring Systems

- 30% improvement in Downtime Management

The success of OT-IT convergence in achieving complete and meaningful industrial communication depends on its intelligent integration with the cloud. Connecting field-device data with cloud applications helps enterprises make quick and informed decisions.

The uOPC Data Bridge is a new product from Utthunga that delivers seamless OT-IT integration with enterprise solutions running on cloud platforms by subscribing to MQTT or AMQP brokers. The OT data is streamed to the cloud environment without configuring or decoding OT devices running on the vendor’s protocol.

About Utthunga

Utthunga is a corporate member of the OPC Foundation and has been a staunch proponent of the OPC standard. We continue to support 50+ industrial automation OEMs and organizations in their OPC implementation journey. Utthunga also actively contributes to OPC UA’s Field Level Communication (FLC) landscape and Field Exchange (FX) standards. To learn more about our OPC Products, visit https://utthunga.com/products/opc/