SPONSORED BY: TAKEBISHI

Optimize Production at the Cutting-Edge: Kita Alps Shinano-no-Mori Water Plant!

~No-Code linkage between production facilities and AI fault detection system~

With a rapidly changing market environment, including market needs, labor conditions, demands for a sustainable society, and regulations, manufacturers are trying to utilize existing data to optimize production in order to improve production efficiency. However, in modern factories, it is challenging to safely and easily access production data at the facility before utilizing them, due to new and existing equipment from various vendors, utilizing a wide array of vendor-specific protocols. The key to leveraging data, is OPC UA, the global, standard, and secure communication interface for the manufacturing industry.

| The next-generation factory model for Suntory Products began operations in 2021 at the Kita Alps Shinano-no-Mori Water Plant. With its advanced construction, it aims to be “a factory that never stops.” More specifically, in the Suntory Tennensui Kita Alps production line, operating data from various machines are collected in real time, and operation and trends are monitored by the Impulse* AI fault detection system.

*Impulse is a fault detection solution provided by Brains Technology, Inc. |

Before this operation was achieved, the maintenance solution, based on threshold monitoring, was in place but other preventive maintenance work was handled manually. This led to human error and required a high level of specialization from workers. So, by utilizing Impulse AI, Suntory Products hoped to detect faults quicker and enact proactive maintenance to reduce downtime.

But they were facing challenges in accessing data from 80 PLCs – from both local Japanese and international vendors, deployed within the facility.

In addition, Suntory wanted a solution that could be configured by field workers without requiring specialized knowledge of communication protocols or AI.

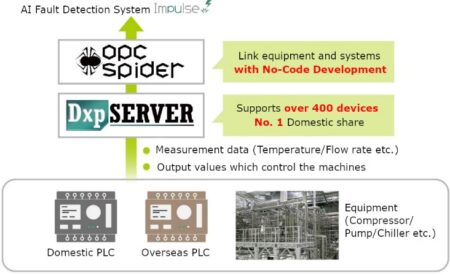

After searching for various solutions, Suntory Products eventually decided to deploy DeviceXPlorer OPC Server (DxpSERVER) and OPC Spider, by Takebishi, for this system.

Roughly 80 PLCs are operating within the factory, from various domestic and international vendors. Data from the PLCs is collected and transferred to the AI fault detection system via OPC UA communication, using DeviceXPlorer OPC Server (DxpSERVER) and No-Code linkage tool OPC Spider, by Takebishi.

By implementing DxpSERVER and OPC Spider, Suntory Products was able to achieve the following benefits:

- Eliminate manual predictive fault detection tasks.

- Realize faster fault detection.

- Improve the operation rate of the facility.

- Enabling the on-site workers to change data collection setting and the system operation, in response to real-time situational assessment.

Read the full success story to find out how Takebishi OPC products were able to facilitate a “factory that never stops” for Suntory Products.

Keywords:

Improved production efficiency, Data analysis, Predictive fault detection

Products Used: DeviceXPlorer OPC Server, OPC Spider

[Hyperlink destination: https://www.faweb.net/en/solution/successstory/suntoryproducts?utm_source=opcconnect&utm_medium=referral&utm_campaign=opcconnect202406 ]