There’s little doubt about it now, the Industrial IoT (IIoT) is here to stay. Access to process data from outside the plant is not longer a luxury, it is rapidly becoming a necessity. Since it has been approved for Industrie 4.0, OPC UA has emerged as the protocol of choice for on-premise industrial data, and it seems a logical choice for many IIoT applications as well. It is a secure industrial protocol with an interoperable data format that provides real-time performance. At the same time, the Internet is a different environment from an industrial LAN, which makes secure industrial data communication over the IIoT more challenging.

The Internet is open and everyone uses it. Alongside fun-loving teenagers and serious executives you find hackers and malicious actors―pervasive and invasive. Opening a plant firewall will attract these pests like ants to honey. So, all inbound firewall ports must stay closed. This would seem to rule out OPC UA from participating in IIoT, since an OPC UA client must connect to an OPC UA server through an open, inbound firewall port. But not so. All that’s needed right now to integrate OPC UA with the IIoT is a gateway and a good IIoT protocol.

The Best IIoT Protocol

The best IIoT protocol should provide, of course, real-time performance, scalability, and support for low bandwidth and low latency connections. But it also needs capabilities that we either take for granted in the OPC world, or that we find newly thrust upon us by the IIoT. These would include an interoperable data format, intelligent overload handling, and the ability to extend quality of service and failure notifications along a chain of connections. Ideally you should be able to exchange data between OPC UA servers and clients through the gateways, DMZs, and cloud servers of the IIoT as seamlessly as if they were connected on the shop floor.

The DHTP Protocol

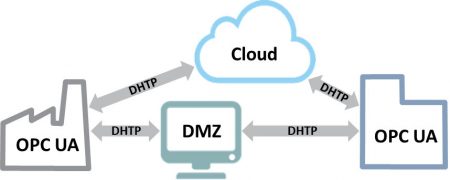

There is one IIoT protocol that meets all of these requirements: DHTP (DataHub Transfer Protocol). Used in industrial applications worldwide and undergoing continual development for more than 20 years, DHTP was created specifically to send and receive industrial data in real time over TCP across a LAN, WAN, or the Internet. The DHTP message syntax is simple enough to implement on even the most resource-constrained devices, and yet sophisticated enough to connect OPC UA clients and servers over the IIoT.

Unlike other protocols like REST, MQTT, and AMQP that were not designed for the IIoT, DHTP supports essential capabilities like an interoperable data format and intelligent overload handling. It also has the ability to daisy chain servers, so that a secure, robust connection can be maintained through gateways, proxies, DMZs, and cloud servers. Using DHTP, if there is a network break at any point along the communication chain, each subsequent link receives this information in turn, and passes it along. This way the client always knows the quality of its data.

Imagine this scenario. A pump goes on, and the OPC UA server informs the client via the IIoT. Then the network breaks, and a little while later the pump stops. The client’s data still shows the pump as running, but can that be trusted? With every change to the connection, DHTP propagates a quality status message along the whole connectivity chain, link by link. MQTT or AMQP may send a Quality of Service message to the first link in the chain, but that information isn’t passed along. The protocol doesn’t support it. If the OPC UA client is not connected to that first link, it will never find out that the connection has broken.

This is just one example of how the special requirements of industrial applications on the IoT call for an appropriate protocol. For over 20 years, DHTP has proven itself to be such a protocol, and is being used in IIoT implementations worldwide. OPC UA provides versatile interoperability, secure within a plant. DHTP allows OPC UA servers and clients to send and receive data securely, in real time, on the Internet. Making connections with DHTP is an easy way to integrate OPC UA with the IIoT.