CONTENT SPONSORED BY: Software Toolbox

For many large global organizations, the sheer quantity of different distributed control systems (DCS) operating different aspects of the operation is an ongoing challenge. At Air Liquide, their air separation units (ASU) and associated equipment around the world are controlled by a diverse assortment of DCS systems. Fortunately, with many of the company’s plants operating in a similar fashion, it became possible for Air Liquide to take advantage of a common library of unit modules. This ability allowed them to standardize consistent, reproducible execution and implement a platform for advanced functionality including Modular Procedural Automation (MPA).

MPA helps automate start-up, shutdown and other data-driven procedures, increasing efficiency, optimizing production, and reducing wear and tear on equipment. And, additionally, MPA helps increase operator productivity and confidence. For example, at one location, MPA lowered startup time by over 60% and increased production to over 500 additional tons of liquid oxygen (LOX) resulting in increased profitability.

Revisiting the previously stated challenge of diverse legacy control system, it is necessary to use a supervisory controller that can be retrofitted onto existing systems and that seamlessly integrates with newer control systems as facilities are upgraded. Further, since the ASUs directly feed pipelines or the clients’ production units, unscheduled downtime for programming changes or code updates to the supervisory controller is extremely costly and, so, is not an option. A vendor-agnostic solution that factors in this diversity of systems and challenges was required.

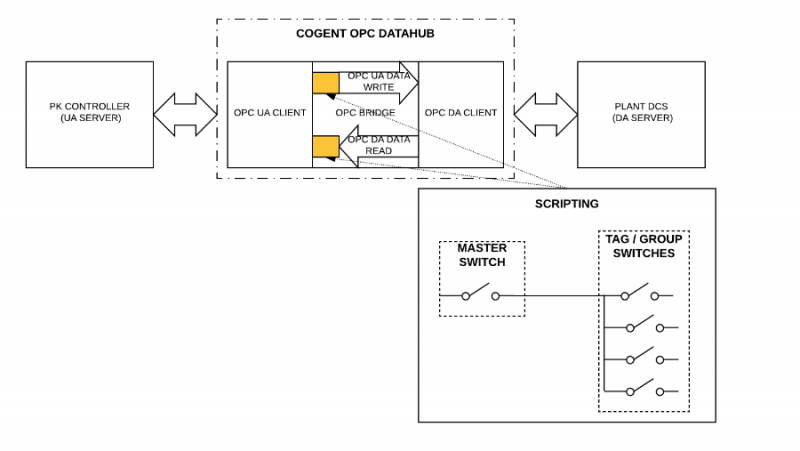

The first implementation of Air Liquide’s Process Unit Modular Automation (PUMA) initiative was deployed at the Ingleside, Texas ASU facility. An Emerson DeltaV PK controller acts as the supervisory platform for MPA with an open OPC UA interface and is connected to a legacy Foxboro DCS with an OPC DA interface through Cogent DataHub. Acting as an OPC gateway, DataHub effectively bridges the classic OPC DA communications from the DCS engineering station with the modern and secure OPC UA interface of the DeltaV PK controller.

How Does MPA Synchronize Process Systems Safely using OPC UA?

In this system, logic allowing writes to protected DCS tags requires that three conditions must be met:

- The OPC UA-enabled PK controller modular logic must be ready to write to the tag group containing the tag.

- Communication from the OPC UA to DA bridge to the DCS and the PK controller is verified to be in a working state.

- The OPC DA-enabled DCS is ready to receive writes.

If all these conditions are not met, the OPC UA to DA bridges to these protected tags will be disabled, and no writes to these tags will take place or even be possible. However, other non-protected tags will continue to be bridged as usual.

To facilitate this conditional bridging functionality, DataHub uses its integrated scripting language. The parameters required for bridging were built into a script that reads from a configuration (.csv) file including the specifications of all bridges, whether they’re protected, and of which PK group they’re a member. This script is designed to be reused on all similar projects in the future, lowering maintenance and maximizing scalability across locations and projects.

MPA Design Sequence

The conditional OPC UA to DA bridging architecture built in DataHub effectively safeguards against all potential situations that lead to inadvertent writes. This necessitates using a specific design sequence in the modular automation procedures. A typical sequence is:

- Disable all OPC UA writes from the PK controller side.

- Wait until the DCS is ready for OPC DA writes and any other logic conditions to be met.

- Synchronize PK OPC UA tags with DCS OPC DA tags.

- Enable OPC UA writes from the PK controller side.

- Run main sequence logic.

- After the sequence is complete, disable OPC UA writes from the PK controller side.

The order of aligning DCS OPC DA tags, enabling the OPC UA to DA bridge, and writing new values to tags is key to ensuring that everything works as required. Following this process precisely makes certain that the first new value written to the protected OPC UA tags in the PK controller gets written to the proper corresponding DCS OPC DA tags.

Successful OPC UA to DA Gateway MPA Proof of Concept

The successful ability to deploy this robust Modular Procedural Automation (MPA) has been demonstrated at Air Liquide’s Ingleside ASU. This is the very beginning of Air Liquide’s larger vision. They’ve demonstrated that if operators can start and stop equipment in more convenient and efficient fashion, those operators will take the steps necessary to operate in the most optimized method whenever possible.

The successful ability to deploy this robust Modular Procedural Automation (MPA) has been demonstrated at Air Liquide’s Ingleside ASU. This is the very beginning of Air Liquide’s larger vision. They’ve demonstrated that if operators can start and stop equipment in more convenient and efficient fashion, those operators will take the steps necessary to operate in the most optimized method whenever possible.

For now, MPA operates in an “operator advisory” mode at Air Liquide. For example, MPA alerts an operator when an argon column’s product tank is full and the column can be shut down, saving significant amounts of energy (as opposed to fully automating that shutdown without operator control).

Ultimately, as operations gains greater comfort and confidence in the MPA process and reliability, the PUMA controller will be able to shut down the column automatically—without operator intervention. And while the MPA’s actions are limited to start and stop for now, the team is considering other data-driven tasks that, as they gain confidence in the solution, can be initiated automatically in the future for further time and cost savings.

As mentioned previously, Air Liquide has seen substantial gains in plant performance after implementing this MPA methodology when comparing post-implementation production to historical production for the same period. For example, one ASU was expected to produce over 500 additional tons of liquid oxygen (LOX) when compared to the same period in the prior year.

And speaking to time-savings, the startup process of the ASU went from 2 hours to 45 minutes – an over 60% reduction – resulting in more time producing product (which translates into increased profits. Additionally, since market demand for argon gas isn’t consistent, it’s possible to more effectively shut down argon production during periods of low demand to switch to liquid oxygen production, increasing profitability in that fashion, as well.

Fore a more detailed version of this story, visit our blog. And for a full nuts-and-bolts deep-dive on this project, you can read the full write-up in Control Magazine by Abdulkadar Susnerwala (process controls engineer), Bruce Eng (advanced process engineer) and Marty Martin (director of process controls) who work together at the Center of Technical Expertise for Air Liquide USA. And our own Win Worrall, Air Liquide account manager at Software Toolbox, was heavily involved in creating the conditional OPC UA to DA bridging script described above.

If you’re not familiar with Cogent DataHub but the use case above is intriguing to you and you would like to try DataHub for your own OPC UA and other integration projects, you can get a free trial of Cogent DataHub. Click to Download Your Free Trial.

Cogent DataHub is a trademark of Cogent Real Time Systems. Software Toolbox is a trademark of Software Toolbox, Inc.