SPONSORED BY:ICONICS

Universal Connectivity

ICONICS designs its automation software solutions to “Make the Invisible Visible”; to discover the numerous data sources scattered throughout an organization and make the best use of that data through visualization, analysis, rapid archiving/retrieval, mobile access, and cloud connectivity. Multiple data sources can utilize a myriad of communications protocols, developed over time and usually with an understandably direct specific purpose. Over its nearly 35 years in business, ICONICS has strived to remain “protocol-agnostic”, with the goal to integrate with as many standards as possible for the benefit of its customers and partners.![]()

OPC UA … Also Platform Agnostic

One specific standard that has helped ICONICS to achieve that goal more than any other standard over the years is OPC UA. An excerpt from ICONICS’ whitepaper titled OPC UA Defined and How It Impacts Automation reads, “OPC UA meets Industrie 4.0 requirements thanks to the fact that it is not based on any one communications technology from any specific manufacturer, sector, operating system, or programming language. In addition to being platform-agnostic, OPC UA can also be widely scaled, from a 15kB device up to multi-core hardware, regardless of CPU. This means the ability to network between individual sensors, embedded devices, PLC controllers, PCs, smartphones, mainframes, cloud applications and more.”

Note: ICONICS provides OPC-to-the-Core™ solutions ranging from a suite of OPC servers and clients to a toolkit for developing OPC Servers. A charter member of the OPC Foundation, ICONICS has assisted over the years with creation of OPC standards, development of the OPC Foundation sample code, and participating and hosting OPC Interop testing. Currently, ICONICS serves on the board of directors for the Foundation. For more information on this working relationship, visit https://iconics.com/Products/OPC-Connectivity.

An additional benefit of adopting a widely integrated communications protocol (such as OPC UA) and a widely integrated automation software suite (such as ICONICS) is the ability to more easily adopt, and benefit from, cutting edge technologies, such as Digital Twins.

Digital Twins on Azure

ICONICS has created a Digital Twins on Azure solution, built on Microsoft’s Azure Digital Twins platform, which provides virtual modeling capabilities for physical environments. ICONICS Digital Twins on Azure delivers value in five key areas: continuous monitoring, conditional alarming, historical analysis, comparisons, and remote configuration.

For manufacturing customers, the solution integrates with ICONICS’ classic remote monitoring, SPC/SQC, OEE manufacturing, and universal connectivity (including with OPC UA) capabilities. Each asset is represented virtually within the twin object model to inform its digital equivalent of real-time updates from connected PLCs, IoT sensors, or the manufacturing equipment itself over the cloud. This powerful integration reduces engineering time, increases productivity, optimizes operations, and offers greater flexibility in customization. By focusing on these core areas of improvement, the manufacturing intelligence dashboard empowers operations managers, directors, and C-level executives to reduce wasted time and resources and increase productivity and quality.

The Digital Twins on Azure solution works in conjunction with ICONICS IoTWorX™ software to perform real-time visualization, collection, and analysis of data coming directly from industrial or building automation equipment or IoT sensors. It gives operators insight into the health of their asset portfolio, as well as allows them to compare equipment, facilities, or shifts to focus on best vs. worst performers using big data analytics to deliver significant savings. The analytics module applies artificial intelligence rules to predict when equipment might fail or use more energy than necessary. By integrating Azure Machine Learning, these predictions will grow more insightful over time, enabling operations managers to prioritize maintenance and remediation.

With Azure Digital Twins, ICONICS can bring even more advanced capabilities to its manufacturing process solutions. ICONICS has incorporated twin object models and a spatial intelligence graph to address powerful use cases in manufacturing scenarios.

IoTWorX™: Bridging the Gap from Edge to Cloud

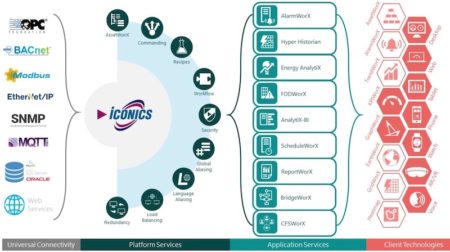

In the nearby images, you can see how ICONICS IoTWorX acts as the “edge layer”, tying in the “universal connectivity” of connected data sources (via protocols such as OPC UA) through its platform services (including asset management, commands, recipes, workflows, security, aliasing, load balancing, and redundancy) and application services (including alarming, historical data collection, energy management, fault detection/diagnostics, BI analysis, scheduling, reporting, data bridging, and connected field service management) abilities to its client-based technologies on any desktop, web browser, or smart device, including augmented/mixed reality hardware, wearables, and voice assistant devices. Another important application for ICONICS Digital Twins on Azure offering is for smart buildings and digital workspaces. Much in the same way that the manufacturing-focused solution makes use of OPC UA, these smart buildings applications typically integrate with devices using the BACnet protocol. The digital twin mapping process still provides virtual modeling capabilities for the physical environment and delivers value in four key areas: energy efficiency, fault detection, occupancy, and comfort. Insightful dashboards empower facility managers, property owners, sustainability directors, and C-level executives to reduce their energy consumption and improve employee productivity through optimized comfort.

Another important application for ICONICS Digital Twins on Azure offering is for smart buildings and digital workspaces. Much in the same way that the manufacturing-focused solution makes use of OPC UA, these smart buildings applications typically integrate with devices using the BACnet protocol. The digital twin mapping process still provides virtual modeling capabilities for the physical environment and delivers value in four key areas: energy efficiency, fault detection, occupancy, and comfort. Insightful dashboards empower facility managers, property owners, sustainability directors, and C-level executives to reduce their energy consumption and improve employee productivity through optimized comfort.

Combination and Expansion

The combination of open communications protocols, such as OPC UA, and software solutions, such as those from ICONICS, helps expand the adoption of some of the latest technology breakthroughs. While the examples described above focused on manufacturing intelligence and smart buildings applications, ICONICS Digital Twins on Azure technology is widely applicable to many other industries.

NEW ‘Edge to Cloud’ Video

ICONICS works in tandem with Microsoft to help companies meet crucial sustainability and emissions goals. Visit https://iconics.com/edgetocloud to watch Microsoft’s and ICONICS’ “Edge to Cloud” video to see how Azure IoT and ICONICS software enables improved operations and reduced environmental impact.