SPONSORED BY: TAKEBISHI

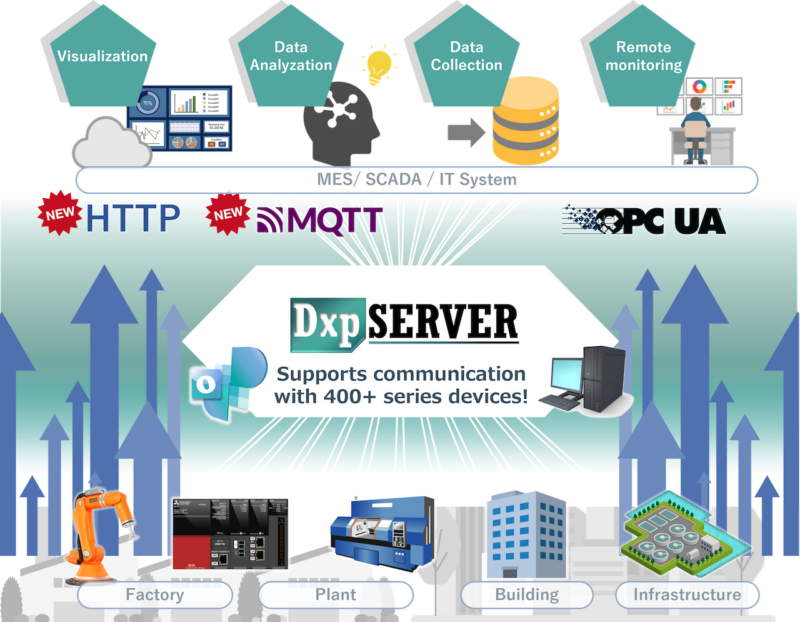

TAKEBISHI CORPORATION offers powerful DX (Digital Transformation) solutions for Smart Factory through OPC servers that provide connectivity with a wide range of devices and services. This article focuses primarily on its new and refined OPC server, DeviceXPlorer OPC Server Version 7.

DeviceXPlorer OPC Server Version 7

In this version, DeviceXPlorer OPC Server has transformed from a general protocol communication driver into a DX Platform for the manufacturing industry. It has extended connectivity to devices with faster communication and supports the latest OPC UA technology, which enables handling of historical data, alarm notifications and structured data. It has also supported direct communication interfaces to the cloud (MQTT and HTTP).

The new updated features of Version 7 are as follows:

- Extension of OPC UA server function

- Supports cloud interfaces

- Usability improvement

- Expansion of device connectivity and performance improvement

- Simplified new lineup

1. Extension of OPC UA Server function

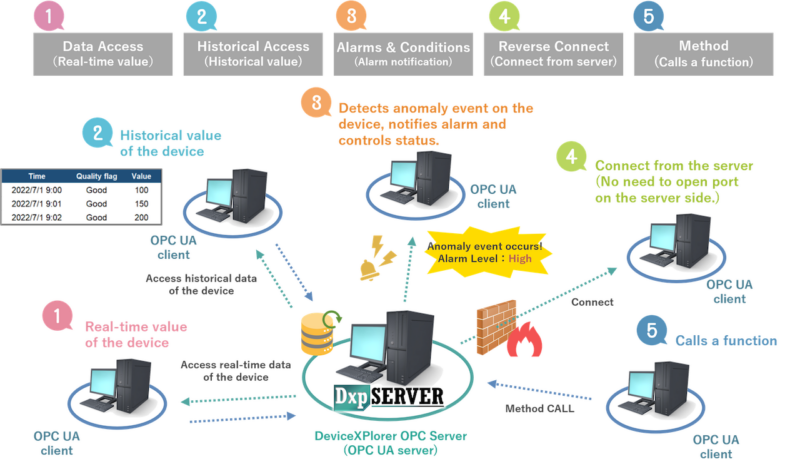

In Version 7, some new specifications are newly supported in the OPC UA server functionality.

Historical Access and Alarms and Conditions

In addition to Real-Time “Data Access” to production data in field devices, Version 7 now supports the function that accumulates historical data (Historical Access) and notify alarms (Alarms and Conditions), which are usually only managed centrally on the MES and SCADA side. This enables us to support primary processing and distributed control even closer to the field side now.

Bypass firewall in server-client configurations (Reverse Connect)

When the production site is connected both to an open network and a closed network, the connection from external OPC UA clients to an OPC server on the production site must be considered carefully. In this case, it is usually necessary to open ports to the outside on the OPC server side. However, open ports on the site should be limited as much as possible to prevent external attacks. Therefore, Version 7 supports OPC UA Reverse Connect specification, which allows DeviceXPlorer OPC Server to make a reverse connection to waiting OPC clients. This makes it possible to access data in the production site from external OPC clients while maintaining security on the production site.

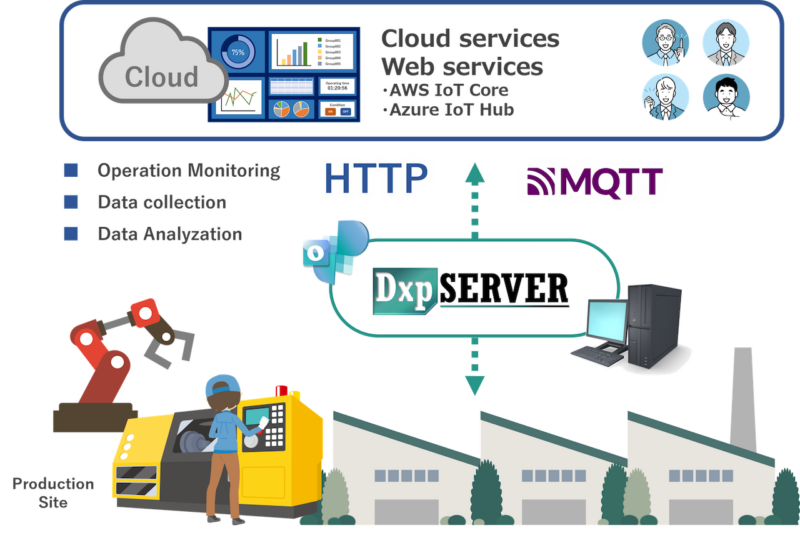

2. Supports cloud interfaces

To enhance further communication with various services, it supports general cloud protocols such as MQTT and HTTP in addition to OPC UA as a higher-level interface. HTTP is widely used as an interface to web services and can be easily integrated with existing web services. MQTT is supported by a variety of cloud services, and MQTT makes it very easy to upload data from the manufacturing site and remote site to the cloud.

As a result, this update will enable cloud services to act more directly on the manufacturing floor by utilizing advanced data analysis and AI technologies to improve production efficiency on the manufacturing site.

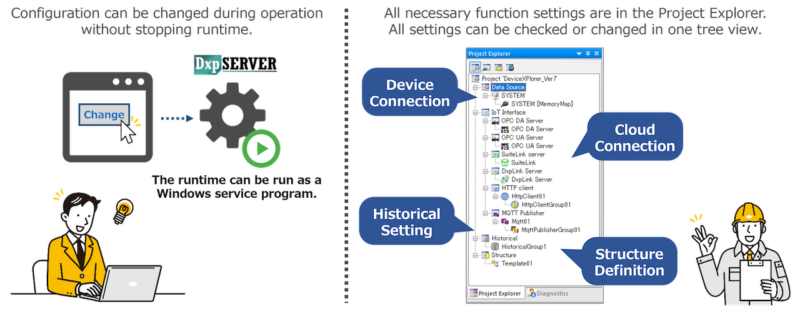

3. Usability improvement

Intuitive usability and user interface are very important factors for a DX platform. The previous versions had the runtime engine and configuration tool combined into a single application, but this makes it difficult to use when running as a Windows service application. Therefore, in Version 7, the communication runtime and the configuration application were separated to improve usability.

In addition, the project explorer, which was only responsible for the centralized management of data sources, has been extended to provide intuitive operability, including a single view of project settings, higher-level interfaces and structures.

4. Expansion of device connectivity and performance improvement

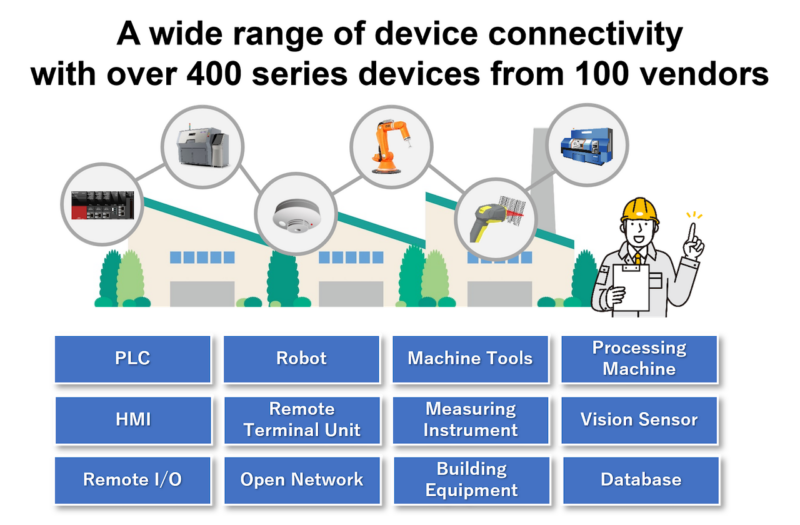

The function as communication driver, connectivity to a wide range of devices and fast communication performance, are also important values as a DX platform. Version 7 supports a wide range of devices and provides connectivity to over 400 device series from 100 manufacturers by supporting vendor-specific protocols from around the world as well as standard protocols such as EtherNet/IP, MT Connect, IEC61850 and IEC60870-5-104.

In addition, the communication performance has been improved by more than 10% compared to the previous version by renewing the application configuration, including separation of runtime and configuration tool, and optimization of communication logs.

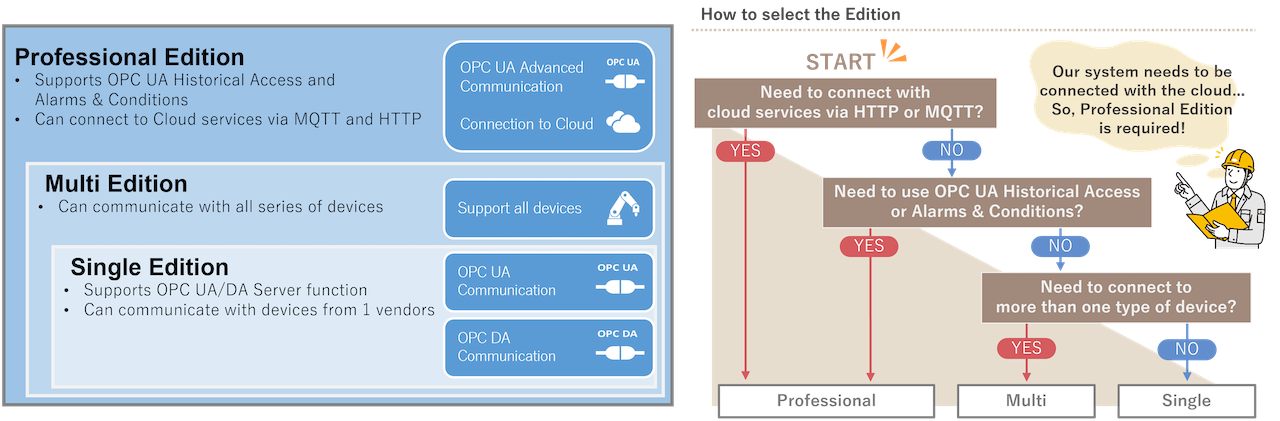

5. Simplified new lineup

Version 7 offers 3 simplified lineups: Professional, Multi, and Single editions. It frees customers from the hassle of selecting the appropriate edition or purchasing the wrong edition. All you need to do is follow the flowchart below.

With all these improvements, DeviceXPlorer OPC Server has evolved significantly as a DX platform.

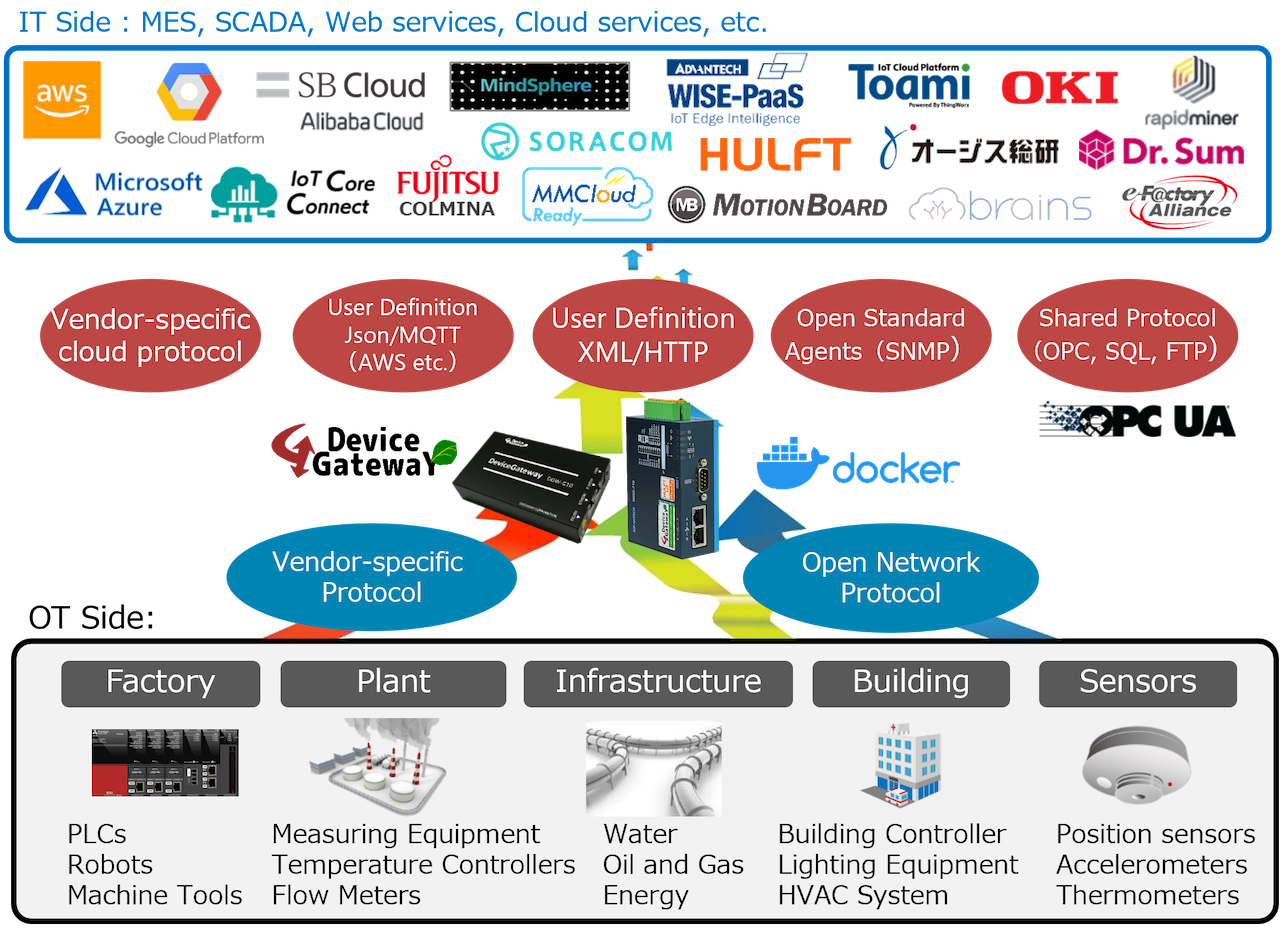

DeviceGateway

Furthermore, TAKEBISHI also offers DeviceGateway, an IoT gateway that provides gateway functionality between a wide range of devices and IoT services. It is available in two product types: as a hardware unit and Docker container software. Docker container software allows users to embed the gateway functionality of DeviceGateway into the hardware of their choice.

ICONICS Powerful HMI/SCADA solution

However, to realize smart manufacturing and digital transformation, it is also essential to have excellent upper-level solutions that utilize data from the production site accessible through DeviceXPlorer OPC Server and DeviceGateway. The right solution for this is provided by our strategic partner, ICONICS Inc., a global software developer of visualization, HMI, SCADA, and energy solutions. They offer the most advanced HMI/SCADA solutions, which are automation software solutions that visualize, historize, analyze, and mobilize real-time information for any application on any device.

For details on each product and solution, including “DeviceXPlorer OPC Server” and “DeviceGateway”, please refer to the following pages on the ICONICS web site.

https://iconics.com/Products/DeviceXPlorer-OPC-Server

https://iconics.com/Products/DeviceGateway-OPC-Server

With our slogan “Connecting the world with TAKEBISHI technology”, we, together with ICONICS and other partners, will continue to provide high value-added products and solutions that meet market and customer needs and contribute to improving customer productivity.