In today’s enterprise infrastructure, system and application integration is more and more frequently a mission-critical concern. Industrial organizations are seeking to tie edge devices into information technology (IT) systems that include manufacturing, enterprise and cloud-based applications. The objective is to take volumes of data and make it easily accessible and useful information for end-users to maximize their efficiency.

The following article describes how the latest collaborative developments of the FDT Group and OPC Foundation empower a single approach to enterprise integration and expand worker mobility in today’s complex industrial operations.

Download the White Paper or Read Further…

Register for Webinar – September 14, 2017 @ 9:00 am CET

Introduction

In order to compete and win in a global, competitive, fast-moving world with increasing customer demands, all kinds of technology must be harnessed and put to good use. But without an effective approach to enterprise integration, all these technologies remain in silos and won’t be useful to the business.

The Industrial Internet of Things (IIoT), along with the Industrie 4.0 initiative, is one of the most significant trends in automation technology. A melding of innovations in the fields of computing and communication, IIoT and intelligent devices are revolutionizing the way users and machines interact, as well as the way machines engage with each other.

Today’s Technology Convergence

It’s to every business’s advantage to think about how to integrate systems, applications, and data. The need for multi-vendor, multi-platform interoperability is prominent in the industrial environment. Current automation architecture requirements are all about security, reliability and data integration between typically disparate devices and applications that have never been connected before.

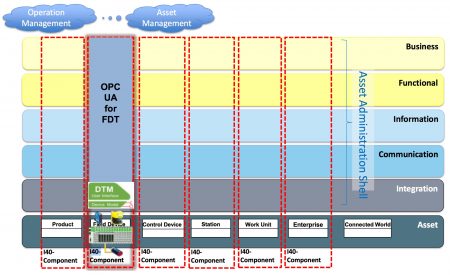

Figure 1: It’s to every business’s advantage to think about how to integrate systems, applications, and data.

Since 2014, the FDT Group and OPC Foundation have worked together to provide greater access to critical information throughout the industrial enterprise. FDT is a well-established integration standard, globally adopted with hundreds of thousands of FDT/FRAME™-enabled control and asset management systems and tens of millions of FDT/DTM™-enabled field devices, while the OPC Unified Architecture (UA) provides an infrastructure to make enterprise information available to thousands of other applications and platforms.

Designed to “Open the Enterprise to Innovation,” the FDT standard intersects the variety of networks attached to intelligent instrumentation and the higher-level systems that interact with these devices. FDT establishes an open, modular and holistic automation architecture that adapts to the changing requirements of suppliers and end-users. FDT incorporates a plant hierarchy based on a physical network topology coupled with a logical topology. The technology supports all the major networks employed in process, hybrid and factory automation, and will accommodate future networks as the industry demands. This approach makes it possible for FDT-based systems to transparently tunnel through disparate networks to gain access, and talk with any end device.

OPC UA, on the other hand, is focused on providing complete information modeling that allows industry stakeholders to take advantage of a service-oriented architecture enabling previously disconnected devices and applications to work together in a seamless manner. For example, OPC UA enables client applications to connect to server applications without understanding the syntax and semantics of the data compiled into the client application. This approach is all about simple discovery of the capabilities of the server, and efficiently leveraging its services and data.

Both the FDT and OPC standards are open, non-proprietary and independent. They provide adaptability as new protocols gain prevalence in the automation industry, and lay the groundwork for future requirements of the IIoT and Industrie 4.0. FDT’s ability to seamlessly nest or tunnel through a myriad of networks to transparently communicate with end devices demonstrates its pivotal position in an intelligent and connected enterprise.

Standard integration of information provided by FDT/DTMs into the OPC UA information model is essential for device diagnostics, configuration and remote asset management, as well for integration with manufacturing execution systems (MES). The FDT/OPC UA information model enhances the management of networks and devices, helping to optimize the enterprise by providing access to data without the need for protocol-specific handling and providing support for a wide range of devices.

OPC UA provides a uniform interface for many different client applications, whereas FDT provides network/device configuration and access to devices. The combined FDT/OPC UA approach enables unification of system engineering, configuration and diagnosis in Industrie 4.0.

Latest Specification Developments

The FDT & OPC collaboration presents a unique opportunity to take the best-of-breed data and information models for the applications and devices supported by the FDT architecture and leverage OPC UA information modeling and corresponding services for complete application-to-device integration. This exemplifies the device-to-cloud computing strategy that supports configuration, communication, run-time and historical data access, as well as alarming and event services for existing and upcoming devices supported through FDT technology.

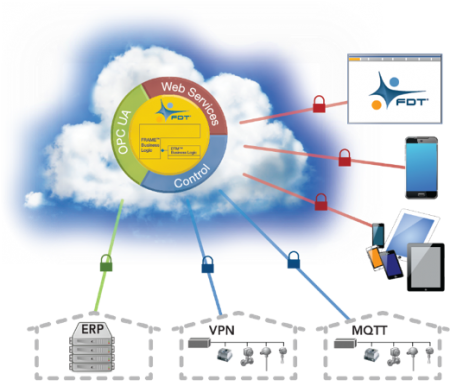

Figure 2: The FDT for OPC UA companion specification provides sensor-to-cloud, enterprise-wide data communication.

In November 2016, the FDT and OPC organizations announced the release of an FDT for OPC UA companion specification for information modeling. It’s an important milestone for standard integration of information provided by FDT/DTMs into the OPC UA information model – a key capability for device diagnostics, configuration and remote asset management, as well for integration with manufacturing execution systems (MES).

Intended for implementation by automation system manufacturers in FDT FRAME applications (FDT/FRAMEs™) embedded in engineering systems, distributed control systems (DCSs), asset management systems and other applications, the FDT for OPC UA companion specification enables true interoperability between applications and devices for configuration, diagnostics and runtime operation. It allows devices and host applications to easily integrate support with IT applications, including information put into the Microsoft Azure cloud. End-users can implement complete log tracking and tracing of information for all aspects of information management, ranging from configuration to runtime operation.

When viewed from an architectural perspective, the FDT/FRAME has access to all control networks in the facility as well as all supported devices attached to the networks. It also has knowledge of the complete control system topology. As a result, the OPC UA server in the FDT/FRAME allows any client application to browse the topology of the control architecture, select an individual device on any network in the topology, and obtain critical operational data about that device – such as its health, its current output value, its tag information, and a wealth of other information. The FDT/FRAME transparently and automatically handles the routing of traffic across all necessary networks so to the OPC UA client, it appears that the device is directly connected.

Any off-the-shelf OPC UA client with the right security privileges can access the OPC UA server embedded in the FDT/FRAME. An example would be an Android tablet application that acts like an OPC UA client but allows a maintenance technician to ascertain the operational status and health of an asset by interrogating the remote FDT/FRAME as he or she roams the facility. To the operator, it will appear as if the wireless tablet is connected directly to the asset in question.

Simplifying the Ecosystem Exchange

Process, hybrid and discrete manufacturing industries achieve significant advantages from IIoT-driven integration of data from development, production and suppliers. This permits manufacturing companies to respond more selectively to individual customer wishes, to react more quickly to market requirements, and also to more easily develop whole new business models.

To advance its support for the IIoT and Industrie 4.0, and to simplify the automation ecosystem exchange, FDT Group has developed an FDT IIoT Server (FITS™). It enables mobility, cloud, and fog enterprise applications, as well as sensor-to-cloud and enterprise-wide connectivity. FITS takes advantage of the FDT for OPC UA companion specification enabling sensor-to-cloud, enterprise-wide connectivity for industrial control systems. It simplifies the move to IIoT, combining OPC UA integration, web services and rich control network interoperability to optimize connectivity and information exchange for the next generation of automation. It features robust layered security addressing all components of the server architecture.

Applicable to both Greenfield and Brownfield applications, FITS protects legacy investments in FDT through advanced business logic and well-defined interfaces. It provides for operating system agnostic implementations of the technology and supports the existing integrated architecture.

The FITS solution (essentially an FDT/FRAME deployed with FDT/OPC information modeling) employs FRAME and DTM business logic at the heart of its client-server architecture. The FRAME interface seamlessly enables operational lifecycle access to asset, commissioning, diagnostic, prognostic, and other higher-level data. To make these data sources available to the open OPC UA architecture, the data is mapped to the OPC UA information model to present it in a standardized fashion. The FDT/FRAME-enabled system can be configured like any other FRAME. OPC UA-based applications requiring access to information from an FDT/OPC UA server take on the characteristics of an OPC UA client. The client requests a secure connection with the FDT/OPC UA server and begins to access topology, device health and other data.

Figure 3: The FITS solution simplifies the move to IIoT, combining OPC UA integration, web services and control network interoperability to optimize connectivity and information exchange.

FITS is specifically developed to broadly extend information exchange in the industrial enterprise. It natively implements OPC UA to enable complete, enterprise-wide connectivity – automatically establishing an OPC UA interface for any client requiring access to the IIoT server, including mobile devices; and making it possible to share information between higher-level applications and the server architecture.

Together, FDT and OPC UA employ a publish-subscribe methodology allowing sensor, network and topology information to permeate the enterprise, including mobile devices, Distributed Control Systems (DCSs), Programmable Logic Controllers (PLCs), Manufacturing Execution Systems (MESs), Enterprise Resource Planning (ERP) systems, the cloud, IIoT and Industry 4.0.

FDT’s network tunneling capability further provides access to meaningful, real-time plant information and asset health data with NAMUR NE107 diagnostics available throughout the plant topology. Along with robust alarming features, this provides support for robust predictive maintenance strategies.

The FITS solution was recently updated with new features aimed at optimizing asset management, preventive maintenance and other critical functions at modern industrial facilities. They include:

- FITS prototyping with a focus on Web Services and mobile device use cases. This includes Web browser and app-based access to the IIoT server. Whereas FDT maintains its core communication and diagnostic capabilities, it now offers remote access to data through mobile devices and web sockets so that other applications can take part in the seamless exchange of information. FITS opens up the automation architecture to allow for more points of access from a data and user interface perspective.

- Mobility apps delivering enhanced business value and empowering the new generation of industrial workforce. Placing information and control in workers’ hands increases visibility so plant processes and productivity can be transformed to achieve new production and maintenance levels. FITS allows for mobility implementations through either OPC UA or the Web Services portal, and underpins two important use cases for the solution – a web browser client and an app connecting to the server via secure web sockets. Future apps will function similar to a plug-in to an FDT/FRAME, but will be easier to standardize via a Web application programming interface (API).

- Augmented reality with FITS using a holographic human-machine Interface (HMI) made possible by Microsoft’s HoloLens computing device. Augmented reality is aimed at achieving context-sensitive increases in human perception so as to relocate information transfer, as well as the traditional, screen-based operation of machines, into space itself. With this approach, users can view real-time and analytic data in a hands-free operation. This includes visualizing sensor status, viewing displays of live data and obtaining support for sensor location. They can maintain their normal field of view with transparent data glasses; virtual content is superimposed over real/physical content.

Role in Global Industry Standards

Deployed in countless automation installations worldwide, FDT technology is incorporated in the international standard IEC 62453, as well as the North American standard ISA103 and China GB/T 29618. Most major system manufacturers today integrate the FDT/FRAME Interface in their solution offerings and more than 8,000 devices are supported by FDT-certified DTMs, making it the most widely adopted standard for integration of devices in industrial control systems.

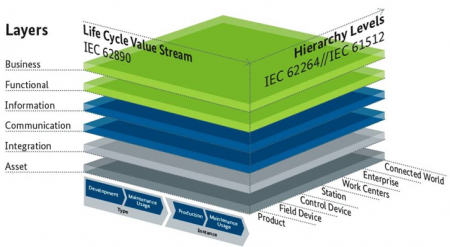

The FDT standard was accepted as the device integration solution regarding the German Reference Architecture Model Industrie 4.0 (RAMI 4.0). With the availability of the FDT/OPC UA companion specification, sensor-to-cloud, enterprise-wide connectivity is granted with seamless integration and data communications. Remote access to connected machines, production units and devices drives key performance improvements.

Figure 4: The FDT standard was accepted as the device integration solution in regard to the German Reference Architecture Model Industrie 4.0 (RAMI 4.0).

At the same time, OPC UA is the one and only recommendation for realizing the communication layer of the common RAMI 4.0 model. OPC UA offers an essential contribution to the standard, starting from vertical integration via consistency of engineering across the entire lifecycle to horizontal integration. The OPC UA modeling tool will also play an important role for the area of semantics where machines, components and products need to be interpreted and understood.

Conclusion

A growing number of industrial organizations are looking for ways to bring systems, applications and devices together to get information throughout the enterprise. With integration of the FDT and OPC standards, they have an optimal approach for multi-network intelligent device configuration and data interchange.

FDT has always provided the highest degree of usability of device, diagnostics and runtime capabilities for simple and complex devices, and leveraging OPC UA now provides the complete solution for exchanging this data and information into other applications areas for a single approach to enterprise integration.