Industry 4.0 is bridging the gap between two worlds: The physical world of machines and material flows – and the digital world with bits and bytes. Building and constantly maintaining a digital representation of physical assets is a big challenge.

The Process and Instrumentation Diagram (P&ID) is the most important document used for designing and building a plant and must legally be kept as an information base during operations. The definition of a common data exchange standard and an alignment of the industry’s terminology is a key factor for the transition from planning to building to operating.

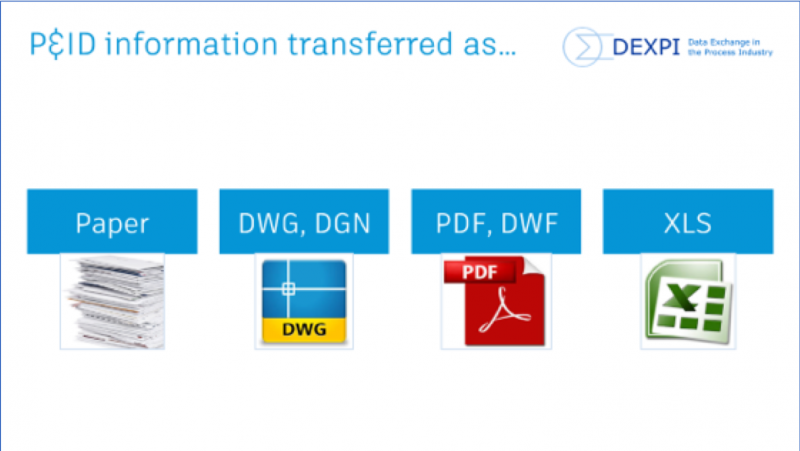

Over the past decades the industry has seen a transformation from paper-based P&ID diagrams and plastic 3D models to digital drawings and models to intelligent digital data. The next step is the horizontal (across P&ID applications) and vertical (e.g. between P&ID and 3D applications) integration of these intelligent digital data.

The new way of designing a chemical plant is that it is no longer necessary to be in the same room with the colleagues to redline and discuss a flow diagram. Digital drawings are not only graphical illustrations but also include meta-data and references coming from other engineering systems or enterprise tools like ERP.

However, unfortunately, it is still also common that digital P&IDs are not exchangeable across software systems. For example, an Engineering Partner (EP) could plan and design a plant in one software solution for P&IDs. The owner and operator (O/O) of that plant most probably uses different software tools and thus cannot simply re-use the P&IDs created by the EP.

Converting the information between different software system formats is usually not possible out-of-the-box and it might sometimes even be required to completely redraw it. This means that intelligent digital data has a limited lifespan and there is no guarantee that it will survive software changes and be available in future for later usage.

Therefore, it is imperative to apply the Industry 4.0 ideas of open data exchange also to P&IDs. In the industry, the DEXPI (Data Exchange for the Process Industry) initiative has developed a data format that supports the move from a document-centric to a data-centric approach, which is the current transition the industry is facing.

Therefore, it is imperative to apply the Industry 4.0 ideas of open data exchange also to P&IDs. In the industry, the DEXPI (Data Exchange for the Process Industry) initiative has developed a data format that supports the move from a document-centric to a data-centric approach, which is the current transition the industry is facing.

The DEXPI initiative was launched in 2011 by a group of owner and operators (BASF, Bayer, Evonik), software vendors (Autodesk, Aveva, Bentley, Intergraph, Siemens), research organizations (AIXCape, RWTH Aachen) and engineering companies (Air Liquide). As of 2018, the number of members has grown significantly, and it is currently being implemented as a PAAT working group of ProcessNet, a DECHEMA and VDI organization.

DEXPI – OPC UA Companion Specification

DEXPI and the OPC Foundation established a working group in Spring 2017 to develop an OPC UA companion specification for the DEXPI data model. The motivation was to provide access to P&ID information using a standard and open and secure communication technology in the context of Industry 4.0 and Industrial Internet of Things. Another advantage of such a companion specification is the easier communication of P&ID data between owner/operators and subcontractors and between design lifecycle phases (e.g. from process design to automation design).

More information: https://opcfoundation.org/markets-collaboration/dexpi/

DEXPI companion specification: https://github.com/DEXPI/Specification/tree/master/specification

For more information on collaborating with the OPC Foundation see:

https://opcfoundation.org/about/working-groups/joint-working-groups/