Beckhoff TwinCAT OPC UA Connects Research and Innovation Infrastructure on Empa Campus

The Swiss Federal Laboratories for Materials Testing and Research (Empa) conduct interdisciplinary energy research in the building and mobility sectors inside an actively used living and working environment on its own campus. Empa relies on the OPC UA communication standard to interconnect its research infrastructure – specifically, three large-scale projects named “NEST,” “ehub” and “move,” plus all the components involved in producing, storing, transporting and converting energy.

Empa, an interdisciplinary research organization and member of the ETH Domain – composed of university and research institutions – is working to bridge the gap between the lab and real-world applications. One primary focus of its work is on energy and sustainable building technologies based on research and technology transfer platforms called demonstrators.These include the Next Evolution in Sustainable Building Technologies (NEST, www.empa.ch/nest), the Energy Hub (ehub) and the demonstrator for future mobility (move).

Open, Clearly Defined Interfaces

Given that Empa’s demonstrators are available to a wide range of users, it was essential to create an open, manufacturer-independent platform with clearly defined interfaces, according to Philipp Heer, ehub Group Leader at Empa: “The individual research and innovation modules (units) have just a single physical link to the central NEST core (backbone) that connects them with the thermal and electrical systems. Each unit operates independently and incorporates its own automation solution, which communicates via Ethernet. The challenge here is to integrate new units into the demonstrator infrastructure with as few limitations.”

Enabling flexible access from outside the Empa campus was another challenge. To achieve this, the process control level was implemented in the cloud. In addition to other requirements, this called for a specialized control system software architecture that would ensure safe system operation yet allow actuator override where necessary for research purposes. For Philipp Heer, OPC UA was the ideal communication technology to meet the requirements for a highly complex and flexible system of this kind: “We use OPC UA across the board, for everything from device-to-device communication at the control level all the way up to data analysis in the cloud and research integration. We developed an OPC UA information model specifically for this purpose. This model lets us integrate new units and components based on standardized specifications. To keep the integration effort as low as possible and ensure consistency, we incorporated parts of the software architecture into the OPC UA information model itself.”

TwinCAT OPC UA Drive Data Communications

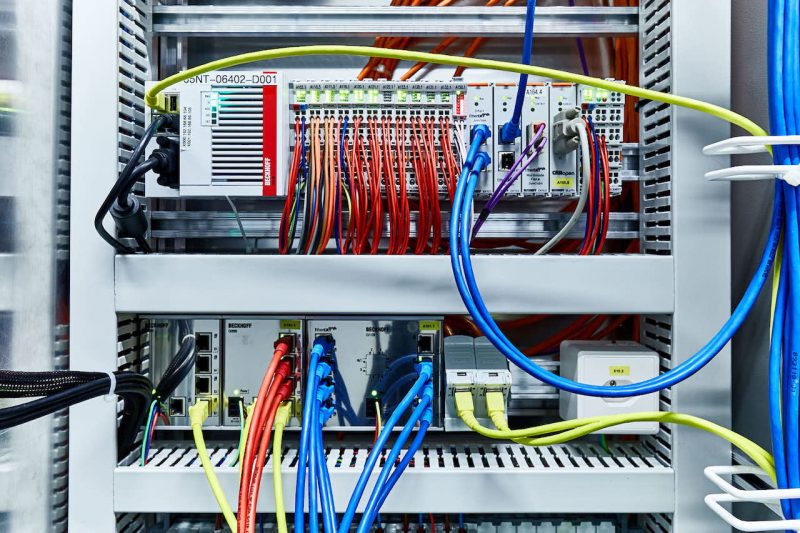

Ten CX5140 Embedded PCs (www.beckhoff.com/cx5140) running TwinCAT OPC UA software (www.beckhoff.com/tf6100) control the communication among Empa’s three demonstrators. Philipp Heer explains: “We have seven CX5140s operating on the NEST backbone as TwinCAT OPC UA servers and clients that we use to connect heating, ventilation and room automation systems. The other three Embedded PCs work as central management systems in NEST to hook up the micro grid and integrate the units. The system as a whole monitors some 60,000 OPC UA objects, including a number of data point instances needed for building automation or to provide researchers write access. Around 6,000 relevant sensor signals from these objects are logged straight to a database. Despite the scale and scope of the system, there have been no performance issues so far. The TwinCAT OPC UA Gateway offers a distinct advantage here: It provides a central point of access to the entire information model, where each sensor is mapped to a corresponding structure.”

Ten CX5140 Embedded PCs (www.beckhoff.com/cx5140) running TwinCAT OPC UA software (www.beckhoff.com/tf6100) control the communication among Empa’s three demonstrators. Philipp Heer explains: “We have seven CX5140s operating on the NEST backbone as TwinCAT OPC UA servers and clients that we use to connect heating, ventilation and room automation systems. The other three Embedded PCs work as central management systems in NEST to hook up the micro grid and integrate the units. The system as a whole monitors some 60,000 OPC UA objects, including a number of data point instances needed for building automation or to provide researchers write access. Around 6,000 relevant sensor signals from these objects are logged straight to a database. Despite the scale and scope of the system, there have been no performance issues so far. The TwinCAT OPC UA Gateway offers a distinct advantage here: It provides a central point of access to the entire information model, where each sensor is mapped to a corresponding structure.”

Another valuable feature from Philipp Heer’s perspective is that the classic building automation system, implemented using the TwinCAT Building Automation Library, can be manipulated directly over OPC UA: “We can override any individual actuator to suit the needs of specific research projects. TwinCAT OPC UA lets us create new instances elegantly and easily within the information model’s tree.”

Another valuable feature from Philipp Heer’s perspective is that the classic building automation system, implemented using the TwinCAT Building Automation Library, can be manipulated directly over OPC UA: “We can override any individual actuator to suit the needs of specific research projects. TwinCAT OPC UA lets us create new instances elegantly and easily within the information model’s tree.”