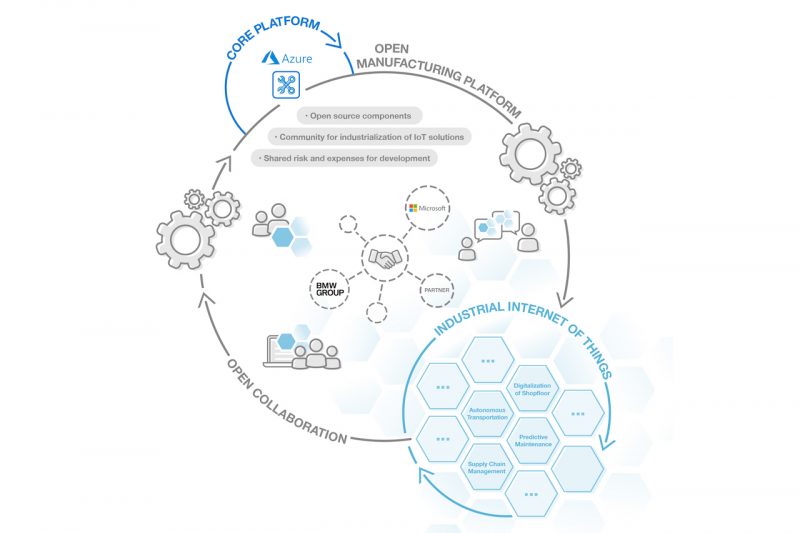

Microsoft Corp. and the BMW Group announced a new community initiative to enable faster, more cost-effective innovation in the manufacturing sector. In manufacturing today, production and profitability can be hindered by complex, proprietary systems that create data silos and slow productivity. The Open Manufacturing Platform (OMP) is designed to break down these barriers through the creation of an open technology framework and cross-industry community. The initiative is expected to support the development of smart factory solutions that will be shared by OMP participants across the automotive and broader manufacturing sectors. The goal is to significantly accelerate future industrial IoT developments, shorten time to value and drive production efficiencies while addressing common industrial challenges.

The OMP will be designed to address common industrial challenges such as machine connectivity and on-premises systems integration. This will facilitate the reuse of software solutions among OEMs, suppliers and other partners, significantly reducing implementation costs. For example, an ROS-based robotics standard for autonomous transport systems for production and logistics will be contributed to the OMP for everyone to use. The OMP will be compatible with the existing Industry 4.0 reference architecture, leveraging the industrial interoperability standard OPC UA.

The OMP will be designed to address common industrial challenges such as machine connectivity and on-premises systems integration. This will facilitate the reuse of software solutions among OEMs, suppliers and other partners, significantly reducing implementation costs. For example, an ROS-based robotics standard for autonomous transport systems for production and logistics will be contributed to the OMP for everyone to use. The OMP will be compatible with the existing Industry 4.0 reference architecture, leveraging the industrial interoperability standard OPC UA.

“This is very good news for the manufacturing industry,” said Stefan Hoppe, President and Executive Director of the OPC Foundation.

“The use of open international industry standards such as OPC UA in the OMP community enables manufacturers, machine builders and suppliers to integrate their existing equipment and systems efficiently and securely. For a long time, companies have promoted proprietary, closed ecosystems — the OMP commitment to open development will shape tomorrow’s manufacturing.” -Stefan Hoppe

Manufacturing is an industry where IoT is having a transformational impact, yet which also requires many companies to come together for IoT to be effective. Microsoft sees several challenges that slow down innovation in manufacturing, such as proprietary data structures from legacy industrial assets and closed industrial solutions. These closed structures foster data silos and limit productivity, hindering production and profitability. It takes more than new software to drive transformation—it takes a new approach to open standards, an ecosystem mindset, the ability to break out of the “walled garden” for data as well as new technology.

Manufacturing is an industry where IoT is having a transformational impact, yet which also requires many companies to come together for IoT to be effective. Microsoft sees several challenges that slow down innovation in manufacturing, such as proprietary data structures from legacy industrial assets and closed industrial solutions. These closed structures foster data silos and limit productivity, hindering production and profitability. It takes more than new software to drive transformation—it takes a new approach to open standards, an ecosystem mindset, the ability to break out of the “walled garden” for data as well as new technology.

This is why Microsoft has invested heavily in making Azure work seamlessly with OPC UA.

“In fact, we are the leading contributor of open source software to the OPC Foundation”, says Sam George, Director, Microsoft Azure Internet of Things.

To further this open platform approach, Microsoft has collaborated with world-leading manufacturers to accelerate innovation in industrial IoT to shorten time to value. “But we feel we need to do more, not just directly between Microsoft and our partners but across the industry and between the partners themselves . It’s not about what any one company can deliver within their operations – it’s about what they can share with others across the sector to help everyone achieve at new levels”, says George.

The broader OMP community is being formed now, with recruitment of additional partners underway. The OMP Advisory Board is expected to be in operation with an initial set of four to six partners in place and a minimum of 15 use cases rolled out into select production environments by the end of 2019. The two initial partners, Microsoft and the BMW Group, encourage other manufacturers and suppliers, including companies from outside the automotive industry, to join the community.

Learn More: https://www.microsoft.com/en-us/enterprise/open-manufacturing-platform