With automation solutions from Siemens and the OPC UA communication standard, Rosendahl Nextrom flexibly connects all production steps. Orders for cable or battery machine production can be implemented more efficiently and complex operating data can be collected simultaneously.

Data Communication with OPC UA in Mechanical Engineering

Rosendahl Nextrom

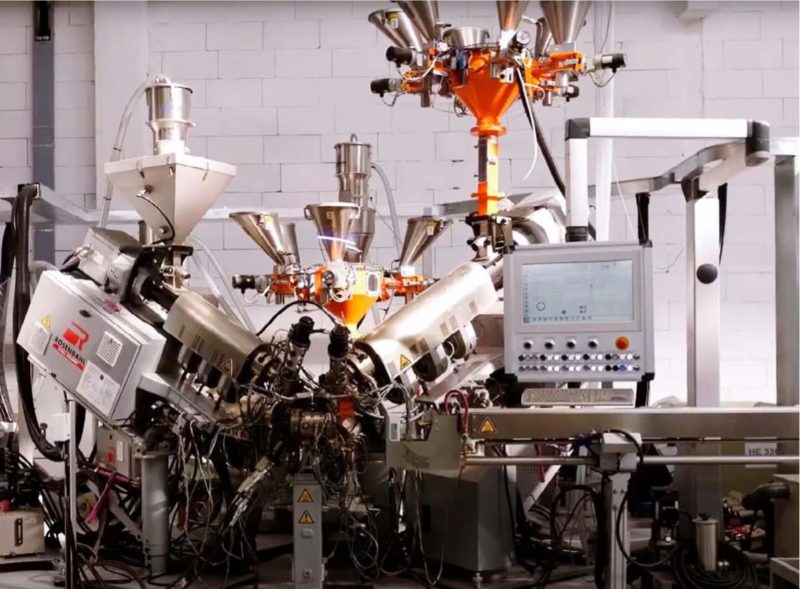

Rosendahl Nextrom develops and manufactures equipment for the global cable, fiber optics and battery industry. The company is part of the KNILL GROUP, an Austrian group focused on industrial manufacturing. It supplies production technologies for battery machines (BM-Rosendahl), machines for the production of cable, wire and shocktubes (Rosendahl), as well as fiber optics and fiber optic cables (Nextrom). Numerous products in the brands’ portfolio demonstrate global market leadership. Depending on the area, the company covers between 25 and 60 percent of the market. At just under 60 percent, the Rosendahl brand generates the largest share of total earnings.

Complex Manufacturing Processes in Cable Production

Cables are produced in numerous manufacturing steps on different machines. The basis for each cable is a single wire or optical fiber. This single wire or fibre is stranded with other elements and coated with a plastic insulation in an extrusion process. In further production steps, several insulated wires are combined to form complex cables and sheathed with a protective jacket. Rosendahl Nextrom’s core competencies include solutions and equipment for drawing glass fibers, extruding, stranding, welding and corrugating for producing cable types for a wide range of applications. This essentially includes cables in the fields of low, medium and high voltage, fiber optics, automotive, communications and special applications.

Manufacturing Solutions for Battery Production

In principle, two technologies can be distinguished: leadacid and lithium-ion batteries, which are used as starter, traction and stationary batteries. The production is divided into three main processes, these are the production of electrodes/cells, the assembly of the battery and the charging and testing of the finished battery. For each step several industrial machines are needed to obtain a battery at the end of the manufacturing process. BMRosendahl develops and produces customized manufacturing solutions in the field of assembly of both technologies. The portfolio includes equipment for the processing of lead electrodes (sleeving, stacking, cast on strap and the assembly to automotive, motorcycle, industrial batteries) and the assembly of lithium-ion modules and battery packs (stacking and compressing, gluing, laser welding, screwing, etc.).

Support via OPC UA

Rosendahl Nextrom has also made a trend-setting decision in favor of the OPC UA communication standard with the objective of problem-free connection of the products to higher-level master computers, machines, customer and cloud systems among other standards. “OPC UA has now become one of the Industry 4.0 standards,” explains Benedikt Wagner, Head of Commissioning and Programming. “Thanks to this solution, we can guarantee high security standards through integrated certificates and user management. On the other hand, the free standard can be adapted dynamically, which perfectly supports our customized approach.”

Areas of Application

At Rosendahl Cable & Wire, OPC UA is used for dual operation between individual machines and the orchestration of the entire plant (M2M communication), as well as for further data collection. BM-Rosendahl additionally uses the communication standard for a vertical data transfer in the direction of MES/ERP systems, which are provided by the respective end customer. The integration of the plants into the data interface provided by the end customer in the direction of management systems is possible without any problems.

Predictive Maintenance Thanks to Semantic Information

Based on historical data and empirical values, analyses that enable predictive maintenance are carried out for each plant. In the extruder section of the plant, for example, tensile stress, temperature and object data are transmitted using OPC UA. Condition data is also collected to optimize the service life of the screws installed there. Unlike other protocols, semantic information is transmitted so that conversions from Celsius to Fahrenheit, for example, are no longer necessary.

Interaction with Automation

In a long-standing partnership with Siemens, Rosendahl Nextrom first develops new plants in a virtual environment. Tests and optimizations take place on the basis of digital twins in the form of simulations. The construction and use of prototypes has therefore become unnecessary. Siemens enables these processes with TeamCenter, TIA Portal, Mechatronic Concept Designer and other tools. One of the benefits of using these automation protocols is the construction of a new machine for the production of lithium-ion batteries. It is not a linked plant, as is usually the case, but consists of individual production cells, which in turn are automated individually. This al- lows the production capacities of the machine to be flexibly increased or slowed down and adjusted to market requirements. Since OPC UA is an open communication standard, all existing automation systems can be connected via plug-and-play without any loss of functionality, regardless of the operating system or manufacturer.

Expansion Possibilities

In the next step, Rosendahl Nextrom wants to incorporate artificial intelligence into data analysis to make farther-reaching predictions. With semantic information, AI can directly relate objects and elements during data analysis, providing a faster and more reliable analysis. OPC UA Alarms & Conditions will also be integrated to provide additional improvements to the process.

Fast Integration into Existing Systems

The changeover to OPC UA took place in the course of a one-month pilot project. Extensive tests were carried out at the pilot plant in the technology center in Pischelsdorf am Kulm. Among other things, it had to be ensured that all required plant components from a wide range of manufacturers could be connected with OPC UA and communicate according to the plant parameters required by Rosendahl Nextrom. The implementation was fast and smooth. The rollout to the operating sites took place promptly.

Reduction of Downtime

“The biggest advantage is, of course, the easier connection of machines to existing systems,” says Benedikt Wagner. “By eliminating hardware adapters, we become more independent and flexible. Conversely, the standard also enables the availability of new process values and comprehensive data access in real time.” According to Benedikt Wagner, these improvements lead to a reduction in downtime of the entire plant as well as to higher quality of the end product.

Uniform Representation of Process Values

The main task of OPC UA in the manufacturing industry is to facilitate communication independent of platform and manufacturer and to overcome the traditional barriers in industrial communication. All separate protocols are combined into a single secure technology. Unstructured data is contextualized to become easily understandable information. Diverse and distributed plant environments and Big Data scenarios in the area of operational technology (OT) benefit significantly from this.