SPONSORED BY: OMRON

The shift to electric vehicles (EVs) is progressing toward the realization of a decarbonized society. In addition, the needs for cars are diversifying along with technological evolution, such as automated driving technology and the sharing economy. The world is changing rapidly, and automakers are required to balance quality with product diversification. In response, manufacturing sites need to deploy production lines more frequently and earlier with quality traceability whilst maintaining conventional productivity.

Challenges for Automobile Manufacturers

- High frequency and early deployment of production lines for a wide variety of products

- Quality improvement

As a result, manufacturers of automotive rechargeable battery equipment are required to support compatibility with the data structure of higher-level data utilization systems and large-volume data communication for quality traceability, while maintaining conventional production tact time on equipment that requires extremely high-speed and multi-axis control.

Challenges for Manufacturers of Automotive Secondary Battery Equipment

- Compatibility with data structures of IT systems

- High-capacity traceability data communication

OMRON’s NX102 Series, NJ501 Series, and NX701 Series machine automation controllers with OPC UA as standard can provide both high-speed, high-precision control and communication with IT systems.

And now we have improved the OPC UA server function to meet the needs of these customers.

Improvements in OMRON’s OPC UA Server Functionality

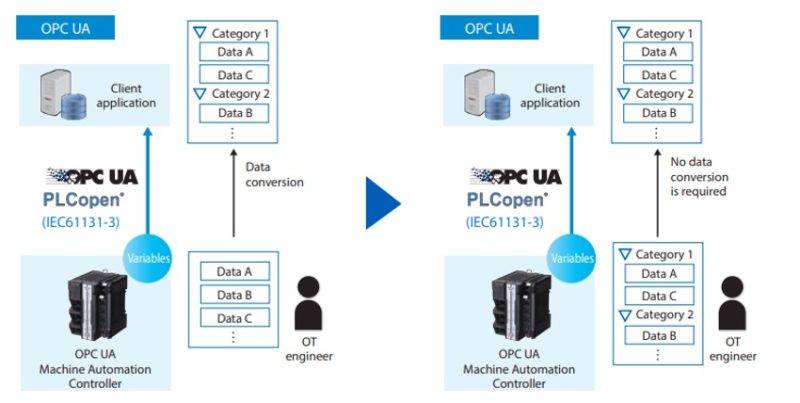

- Support for variable structuring

This improvement increases compatibility with the data structure of IT systems. It enables the construction of the optimal data structure for the purpose of the production site and reduces the additional work of complicated data conversion in the IT system.

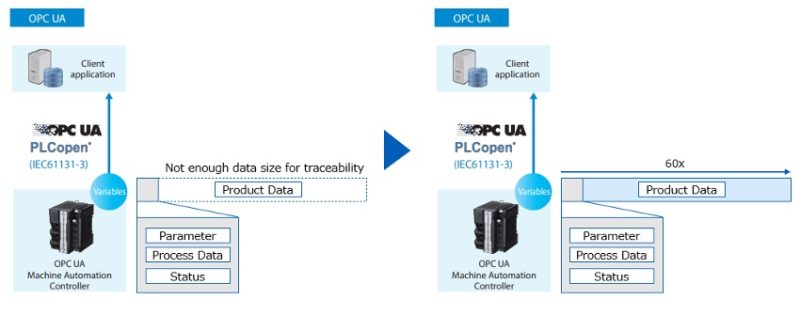

- 60x expansion of the size of data that can be communicated with IT systems

This improvement enables communication of production instructions and other information with the conventional MES and communication of quality traceability at the same time, contributing to quality improvement.

A manufacturer of automotive secondary battery equipment that has adopted the flagship NX701 Series with these improvements has achieved equipment that is compatible with the data structure of IT systems and supports large-volume traceability data communication while synchronizing control of machines that require control of more than 100 axes with EtherCAT. The equipment is now compatible with the data structure of the IT system and large-volume traceability data communication.

OMRON will continue to evolve OPC UA as an important project. We will continue to help solve our customers’ challenges by incorporating the latest technologies.

Takuya Ueki

Takuya Ueki

Global product manager, Controller

Omron