SPONSORED BY: TAKEBISHI

Takebishi Corporation released a new version of its industrial communication software “DeviceXPlorer OPC Server (DxpSERVER) Ver.7” on November 30, 2022. In this latest version, DxpSERVER has transformed from a general protocol communication driver towards a DX Platform (data communication platform) for the manufacturing industry.

In the manufacturing industries, Manufacturing Execution Systems (MES) have been built in closed networks, focusing on a smooth manufacturing process based on a production plan (with control and visualization of the field devices) and traceability management.

DxpSERVER acts as a communication driver towards connecting between field devices and MES via OPC, the international communication standard protocol (IEC62541).

Today, in the remarkable developments of cloud, 5G/wireless and AI technology in IoT and DX trends, the effort to realize the Smart Factory using these technologies in the manufacturing process, are also accelerated.

A Smart Factory is a factory that not only implements a production plan, but also can flexibly cope with ever-changing order statuses or production data as well as changing external factors such as social conditions and consumer sentiment.

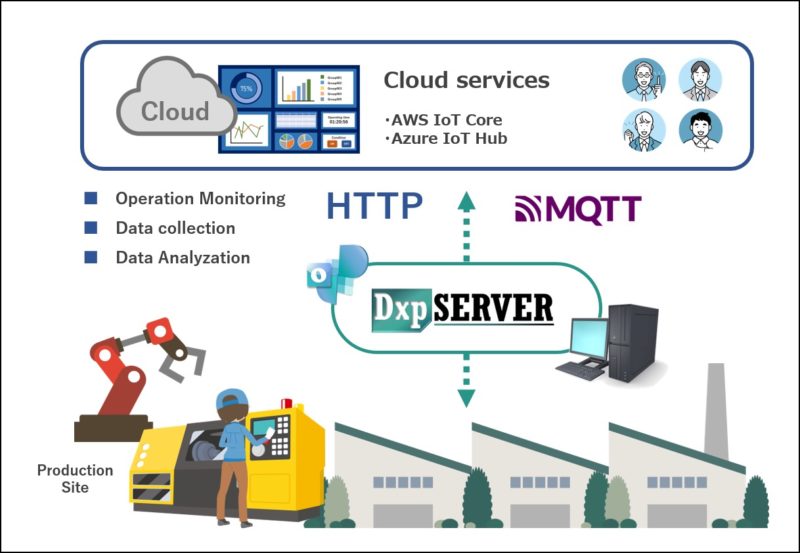

Thus, there is no doubt that it is most efficient to realize the Smart Factory that connects manufacturing sites and cloud services using inexpensive and easilyy installable state-of-the-art technologies.

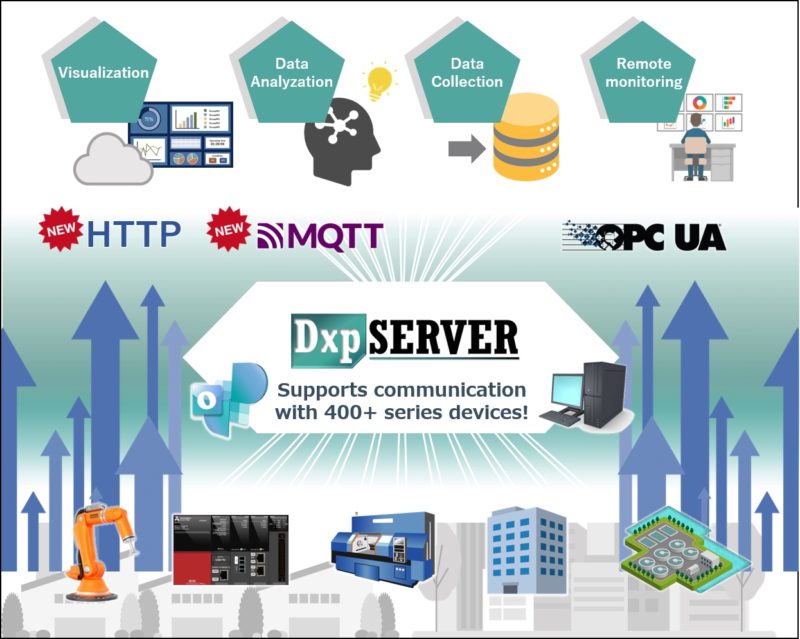

Now DxpSERVER has evolved into a data communication platform (DX platform) in order to realize Smart Factory. DxpSERVER Ver.7 has extended connectivity with field devices and higher-speed communication and supports the latest OPC UA technology which enables handling of historical data, alarm notifications, structured data and support cloud communication interfaces (MQTT and HTTP).

The main features of DxpSERVER Ver.7 are as follows:

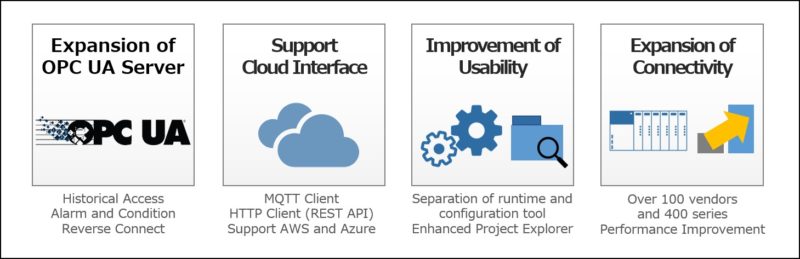

- Extension of OPC UA Server function

- Support Cloud interface

- Improvement of usability

- Expansion of Connectivity and Performance

Extension of OPC UA Server Function

In ver.7, DxpSERVER supports various new features as OPC UA Server.

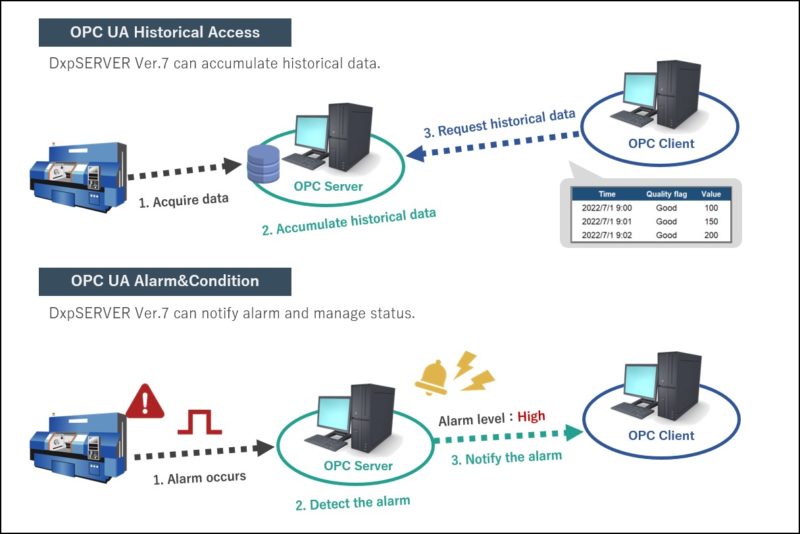

Historical Access and Alarms&Conditions

In addition to Real-Time “Data Access” to production data in field devices, DxpSERVER Ver.7 now supports the function that accumulates historical data (Historical Access) and notify alarms (Alarms&Conditions). Until now it is often only managed centrally by the MES. DxpSERVER Ver.7 can support primary processing and distributed control even closer to the field side.

Information Model

In a manufacturing site, various devices are mixed together, their roles and data structure also vary. When building these systems, a person who understands the devices must intervene to connect the device and the systems. However, the OPC UA specification has a framework called an “information model” that structures the device information, and it enables communication between devices such as M2M or C2C, without intervention of a person. OPC Foundation and various industry standard organizations have been working together to formulate a standard information model for each industry (OPC UA Companion Specifications), with some already being used in Europe.

DxpSERVER Ver.7 defines arbitrary OPC UA information models using a function named ‘structural template’ and also provides a function that enables allocation of each data source of a device, using ‘structure tags’. These tags can be created based on the defined information model, which allows DxpSERVER to communicate with devices using information models.

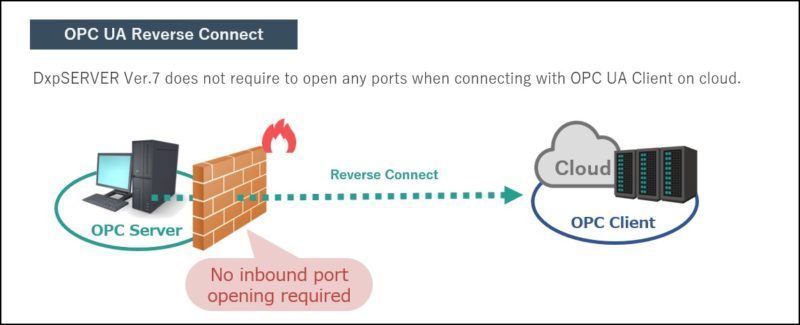

Bypass Firewall in Server-Client Configurations (Reverse Connect)

When the production site is connected both to an open network and a closed network, the configuration of connection from an external OPC UA client to the OPC server at the production site must be considered carefully. When external OPC Client access to OPC Server in the production site is needed, the OPC Server must open network ports to the outside. This does not meet the requirement to reduce the number of open ports to prevent external attacks.

Therefore, Ver.7 supports the OPC UA Reverse Connect specification, which allows the OPC Server to make a reverse connection to the waiting OPC Client. This makes it possible to access data in the production site from external OPC Clients while maintaining security.

Support Cloud interface

To enhance further communication with various services, DxpSERVER Ver.7 supports general cloud protocols such as MQTT and HTTP in addition to OPC UA as a higher-level interface. This will enable cloud services to act more directly on the manufacturing floor by utilizing advanced data analysis and AI technologies to improve production efficiency on the manufacturing site.

Improvement of Usability

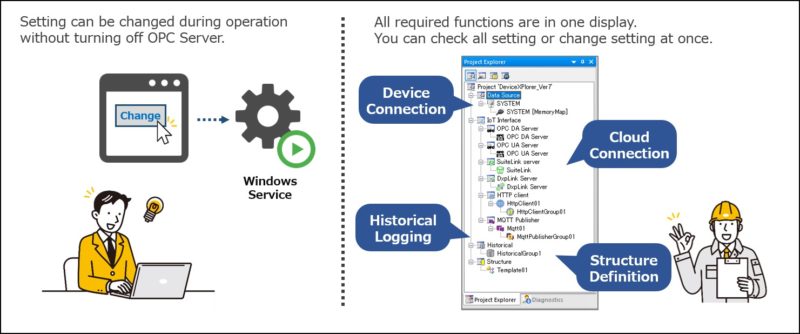

Intuitive Usability and User interface is a very important factor for a DX platform.

DxpSERVER, in the previous versions, had the runtime engine and configuration tool combined into a single application, but this makes it difficult to use when running as a Windows service application. Therefore, in Version V7, the communication runtime and the configuration application were separated to improve usability.

In addition to changing the application configuration, the project explorer, which was only responsible for the centralized management of data sources, has been extended to provide intuitive operability, such as the settings in the project in a single view, including higher-level interfaces and structures.

Expansion of Connectivity

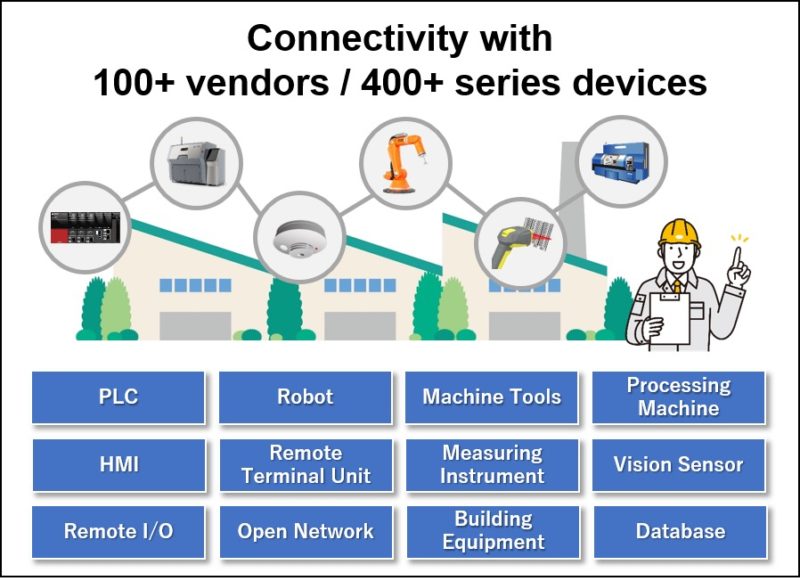

The function as communication driver, connectivity to a wide range of devices and fast communication performance, is still an important value in the new version as a DX platform. The new version supports PLCs from all over the world and standard protocols such as Robot, machine tool (NC), remote terminal unit (RTU), MT Connect, and IEC61850, providing connectivity for 400 products from 100 different vendors.

In addition, the modified application configuration – separation of Runtime and UI- and optimized communication logs have improved communication performance by more than 10% compared to previous versions.

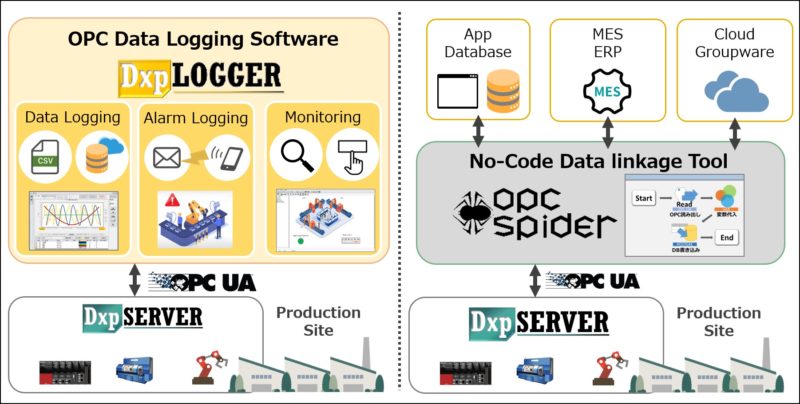

Thus, DxpSERVER has evolved significantly as a DX platform. However, to realize the Smart Factory, it is also essential to have excellent upper-level solutions to control the devices and data obtained through such communication. Takebishi also offers these solutions such as:

- DeviceXPlorer Data Logger: it centrally manages OPC Servers and provides data collection, alarm monitoring and visualization.

- OPCSpider: it provides easy, no-code data linkage between manufacturing data and mission-critical systems such as Enterprise Resource Planning (ERP)

For more information, please visit our website: https://www.faweb.net/en/.

Other useful solutions are provided by ICONICS, a US based company and partner of Takebishi. Their SCADA software solutions are used worldwide in the automotive, building automation, food & beverage, public infrastructure, manufacturing, petrochemical, pharmaceutical, renewable energy, utilities, and water/wastewater industries.

For more solutions including SCADA “GENESIS64”, please visit https://iconics.com/.

With our slogan “Connecting the world with TAKEBISHI technology”, Takebishi will continue to expand its functions to meet the market and customer needs along with partners such as ICONCIS and provide high value-added products and solutions which contribute to the improvement of customer productivity.