SPONSORED BY: OMRON

OMRON’s Commitment to a Decarbonized Society

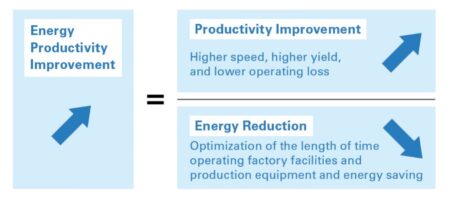

Amid the growing trend toward a decarbonized society to halt climate change, OMRON is taking on new challenges to achieve carbon neutrality by becoming the first manufacturer to declare its membership in EP100*¹, an international initiative to improve energy productivity. Omron is working to improve energy productivity throughout the value chain, including customers and partners, by providing technologies and solutions with the goal of doubling energy productivity*² at all locations in its mainstay control equipment and healthcare businesses by 2040.

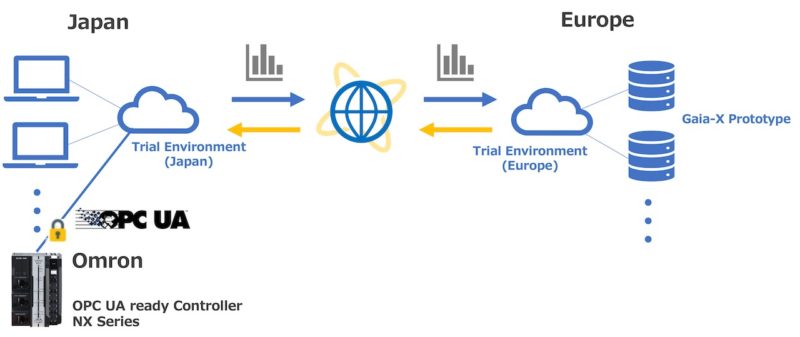

“GAIA-X” Interconnection Trial

One of these activities is participation in the interoperability verification experiment of GAIA-X, a European integrated data infrastructure project launched by NTT Communications Corporation (NTT Com) in October 2021, using controllers with OPC UA as standard equipment.

(Contributing to Secure Data Utilization in Supply Chains with OPC UA)

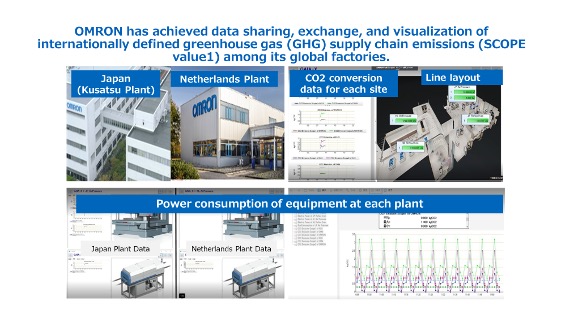

As a result of this activity, data sharing, exchange, and visualization of internationally defined greenhouse gas (GHG*3) supply chain emissions (SCOPE value1) between OMRON’s plants in Japan and the Netherlands was achieved.

“GAIA-X” Interconnection trial result

Future Initiatives

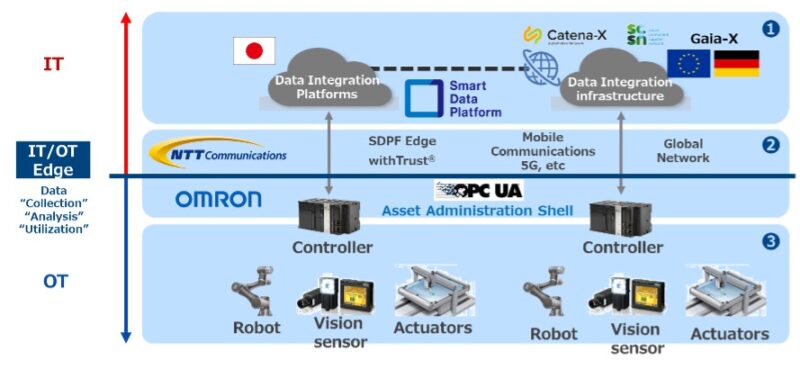

This initiative will now be expanded. Specifically, the two companies will jointly build an experimental environment that links OMRON’s manufacturing site automation technology, experience, and broad lineup of control equipment with NTT Com’s ICT infrastructure to develop and provide a solution that enables the sharing of OT data throughout the supply chain while protecting data sovereignty. The main activities are as follows

- Practical application of a data collaboration platform that enables interoperability with various data collaboration platforms in Europe

By utilizing NTT Com’s data utilization platform “Smart Data Platform*4” (hereinafter referred to as “SDPF”) and the data collaboration platform*5 developed by NTT Com and NTT DATA Corporation (hereinafter referred to as “this platform”), interoperability with various European data collaboration platforms such as “Catena-X*6” and “SCSN*7” will be realized. Furthermore, we will make practical use of this platform, which enables international data linkage, such as CO2 emissions, while protecting data sovereignty, and provide solutions in the IT domain that utilize this platform.

- Interconnection verification to securely link IT and OT domains

The two companies will securely interconnect the platform, located in the IT domain, and the controller, located in the OT domain, to share OT domain data related to products and production between companies in the manufacturing industry. We will jointly verify a mechanism that connects OMRON’s controllers with mobile-based networks such as 5G, global networks, the edge computing service “SDPF Edge*8” and “withTrust*9” to precisely collect, analyze and utilize data on raw material types, energy consumption, quality and other factors identified during the production process.

- Realization of manufacturing sites with both high productivity and energy efficiency

By providing automation solutions in the OT domain that embody OMRON’s unique manufacturing site innovation concept, “i-Automation!. The carbon footprint minimized by optimizing the operation rate and control methods of equipment at production sites will be elaborately databased to enable the reduction and visualization of CO2 emissions. In addition, we will begin joint technical verification to visualize the usage and disposal status of each resource for resource recycling and to realize the promotion of reuse.

Takuya Ueki

Takuya Ueki

Global product manager, Controller

Omron

*1: EP100 is an international corporate initiative organized by The Climate Group, an international environmental non-profit organization headquartered in the U.K., in which companies that aim to double their energy productivity (e.g., improve energy efficiency by 50%) in their business activities participate. EP100 stands for “100% Energy Productivity,” which means doubling the energy efficiency (Energy Productivity) of a business.

*2: Ratio of economic productivity to energy consumption. An indicator that places the absolute amount of energy consumption in the denominator and sales or value added in the numerator, aiming for both reduction of energy consumption and economic business growth.

*3: GHG = Greenhouse Gas. GHGs emitted directly and indirectly from the company’s own territory (Scope 1 and 2)

*4: “Smart Data Platform” is NTT Com’s next-generation platform that provides all functions necessary for enterprise DX in a one-stop shop.

*5: The Data Federation Platform is a new data federation platform that can be interconnected with European data federation infrastructures and is being developed by NTT Com and NTT DATA Corporation based on technology provided by Nippon Telegraph and Telephone Corporation. NTT Com and NTT DATA are working together with industry associations and companies that are facing challenges in data collaboration to promote data collaboration, which is necessary to achieve carbon neutrality, a resource-recycling society, and a stable supply of electric power. https://www.ntt.com/about-us/press-releases/news/article/2022/0427.html

*6: “Catena-X” is a data collaboration platform operated by German automobile manufacturers and others. It enables secure data linkage among various companies, groups, and organizations, and aims to realize the calculation of CO2 emissions during EV battery parts manufacturing and digital transactions among companies across countries and regions. Please refer to the following web page: https://catena-x.net/de.

*7: SCSN (Smart Connected Supplier Network) is a Dutch data integration platform that enables secure data integration of data used in the manufacturing supply chain. Please refer to the following web page: https://smart-connected.nl.

*8: “SDPF Edge” is an edge computing service that realizes a distributed computing model that ensures real-time performance and reduces communication volume by placing servers close to terminals in SDPF to process data. It provides a managed edge computing infrastructure, a server virtualization function that can be equipped with edge applications, for a fixed monthly fee that integrates operation. https://sdpf.ntt.com/services/sdpf-edge.

*9: “withTrust®” is a mechanism for securely distributing and linking highly confidential data.