SPONOSORED BY: SOFTWARE TOOLBOX

You have made significant investments in your industrial control systems to leverage the many benefits of OPC technology over the years. Rip and replace to evolve with technology is not a good or economical option for running systems, but over time you need to move to OPC UA for the benefits of security, resilience, single common infrastructure, expanded functionality and more. If you’ve been using DCOM with OPC Classic servers, surely you know about Microsoft’s DCOM hardening initiative, which further highlights the importance of OPC UA.

In this article, we’ll discuss the following areas where you can use OPC UA technology to get the most from your industrial systems:

- Renewing Your OPC Investments: How to Move to OPC UA

- ERP Integration using OPC UA Data Access, Methods, Pub/Sub & Companion Specifications

- Leveraging OPC UA Historical Access for Contextual Analytics and Decision Making

Renewing your OPC Investments: How to move to OPC UA

We believe most of you have system architectures that have grown over time and are a mix of standards. By now you probably have a system that is a mix of the original OPC Classic standards, such as Data Access or DA, and OPC Unified Architecture (UA) implementations. If you’re someone that implemented OPC starting with the UA standards, then congratulations!

Many major OPC Data Access (DA) server and client vendors long ago added support for OPC UA in their products and offer you a clean upgrade path that adds OPC UA side-by-side your OPC DA interfaces. If that is your situation, congratulations again! But what about the rest of the world?

What about systems that aren’t UA ready?

There are a few reasons why a system might not be UA ready:

- Vendors have not updated their products to offer a clear path to OPC UA or they have only done it for their OPC DA interfaces but not others.

- Field installed devices using OPC XML-DA cannot be upgraded to support OPC UA.

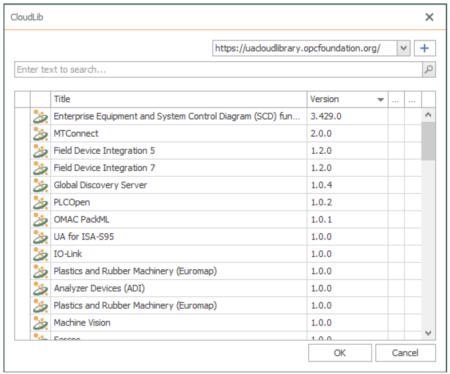

- You want to leverage functionality in OPC UA such as UA Methods, Pub/Sub, or Companion Specifications.

- You’ve received a new system that despite your specifying OPC UA, has delivered it without and without an upgrade path.

Solutions to Leverage Your Investment in OPC

We have worked with OPC since its inception, so we have seen many customer use cases, and can offer you off-the-shelf solutions to move to OPC UA. Here are some options but most importantly, our technically focused team is accessible and willing to discuss your specific requirements, just contact us!

DataHub OPC Gateway – Learn More – converts:

- OPC DA to OPC UA and back for clients & servers.

- OPC A&E to OPC UA Alarms & Conditions and back for clients and servers.

- OPC A&E to OPC UA (DA Profile) – Breaking the alarm structure elements into individual OPC UA items.

- Optional secure DMZ, proxy friendly tunneling.

OPC Router – Learn More –converts & integrates:

- OPC DA server to OPC UA data access client or server

- OPC DA servers and other data sources with OPC UA Methods, Pub/Sub, & Companion Specifications

- REST, SOAP Web service to OPC UA data access & other standards

TOP Server OPC Client Suite – Learn More – converts:

- OPC XML-DA server to OPC UA server

- OPC DA server to OPC UA server and reverse

- Support for passing dynamic tag addresses down from the HMI/SCADA client

- Great add-on for users already using TOP Server for AVEVA applications.

These options make it possible to bring your prior investment in OPC technology forward as part of your Industry 4.0 initiatives.

ERP integration using OPC UA Data Access, Methods, Pub/Sub & Companion Specifications

Now let’s move on to discuss another requirement for many organizations in the manufacturing industry. The manufacturing environment is a competitive space. Manufacturers aim to deliver the best quality products in the shortest time to maximize profits. Most manufacturers utilize Enterprise Resource Planning (ERP) systems to handle business functions such as financial management, purchasing, inventory, sales, analytics, and reporting.

For manufacturers to become more agile and responsive to change and achieve optimal results, it is imperative to integrate OT / shop floor data into the ERP system beyond non-real-time traditional file or database table exchanges. Rapid time to result solutions with real-time connections to OT, IoT, and widely implemented ERP systems that are suitable for OT practitioners to implement in collaboration with their ERP administrators are needed.

In some cases, ERP systems may have their own native OPC UA connectors, but many still rely on web services using REST or SOAP implementations. With OPC UA being the standard for interoperability in industrial control, solutions to bridge the interfaces are required. In cases where an ERP system has an OPC UA connection, there could be cost constraints or functionality gaps in what parts of the OPC UA standard are supported, including OPC UA Methods, Pub/Sub, and Companion Specifications. Because no two user use cases are the same, and these features of OPC UA are growing in popularity, it is not optimal to have multiple integration points. Cost effective alternatives that consider the needs of OT practitioners are necessary.

The OPC Router is a standard software solution that supports many different protocols to network different machines and systems, including OPC, databases, automation hardware, IoT/Cloud systems, and ERP systems. The OPC Router functions like a universal translator or gateway with visual workflow configuration, edge deployment support, and can be integrated into existing automation and production environments easily, quickly and without expert knowledge or programming skills.

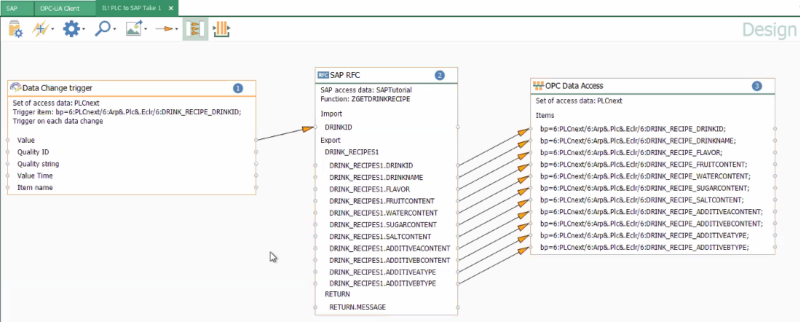

For SAP ERP systems, native, certified SAP connectors supporting RFC, BAPI, IDoc, NetWeaver, and HANA are provided by OPC Router that do not require additional software from SAP. They are suitable for OT practitioners to implement in collaboration with their SAP administrators for real-time two-way data exchange with OPC UA empowered systems. OPC DA (Classic) systems can also be integrated with ERP with OPC Router. OPC A&E and HDA Classic applications can be modernized using DataHub as described in the rest of this article. Below is an example integrating OPC UA with SAP.

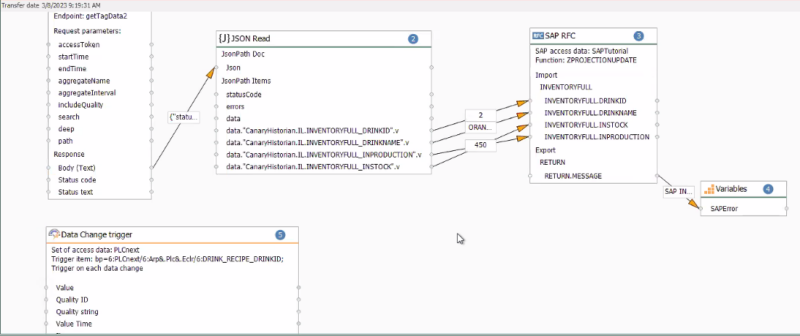

With other ERP systems, they usually support REST and SOAP web service connections. OPC Router includes support for REST and SOAP web services with visual tools for extracting data using XML (XPath), JSON (JPath) and then visually mapping the data to OPC connections, databases and more. In the example below a data change trigger from an OPC UA point in a PLC triggers a REST web service read and transfer of data.

On the OT side, OPC Router supports production specific protocols like OPC UA, OPC UA Methods and Companion Specifications, OPC UA Pub/Sub, OPC DA Classic, printers, RFID readers, and many others. Once connectivity is established by OPC Router, workflows are visually configured and then automated to be triggered from operating conditions, operator requests and more, and processes optimized to move data between plants, devices, and systems.

View an on-demand ERP to OT virtual workshop that integrates a PLC, Historian, and ERP system using OPC UA and OPC Router to learn more.

Leveraging OPC UA Historical Access for Contextual Analytics and Decision Making

And last, but certainly not least, we need discuss how historical data (if it isn’t already) can play a pivotal role towards actionable intelligence in your organization using data sources you almost certainly already have at your disposal and accessible with OPC UA Historical Access.

We’ve all heard the management mantra, “You can only manage what you measure”. We see this in our personal lives all the time. If we decide to lose some weight, the first thing we do is jump on a scale. As we start losing weight, we’re encouraged to do even better. A wearable fitness device takes our weight loss program to a whole new level by adding additional health related measurements, encouraging us even further. The result of this measurement drives our behavior. In fact, in many cases, the mere act of measuring has a positive effect on behavioral outcome. This is known as the Hawthorne effect.

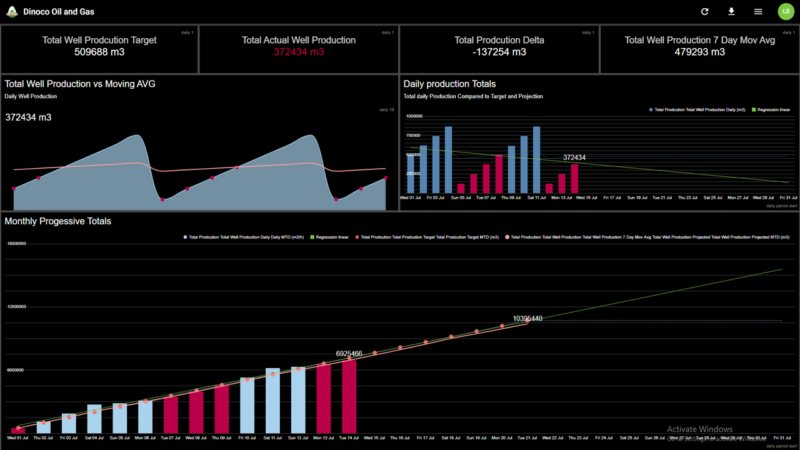

In our professional lives in Industrial and Manufacturing management roles, this measurement effect is no different. In order to manage a process, we need to measure the results of that process. If we start measuring the production output of a machine or the performance of a process, for example, the people responsible for running and maintaining that machine or process are more likely to pay attention and take the necessary decisions to improve its performance.

If we logged these measurements over time, we could look back at the effect of certain decisions made. Together with analysis and the resulting understanding of these effects, the historical data could be used to make more calculated fact-based decisions going forward, ultimately leading towards predictive analytics.

To that end, Flow Software, a highly flexible and scalable analytics and industrial data ops platform, has the ability to connect to OPC UA Historical Access (HA) historian data sources (amongst others). The most significant difference between classical OPC and OPC UA is that it doesn’t rely on OLE or DCOM technology from Microsoft for security. In contrast to OPC Classic, OPC UA was designed with the goal of being “firewall-friendly”, i.e. it can be operated across standard network technology. Coupled with robust encryption and authentication options, this results in very secure communications. This also enables platform independence and interoperability, making it possible to implement it on any platform including Windows, Linux (JAVA), UNIX or even Apple (Mac).

The other very important part of OPC UA is the ability to use structures or models. This means that Flow Software can group the data tags or points and give them context, which makes governance and maintenance much easier. These models can be identified at runtime, which makes it possible for a client to browse possible connections without needing to preconfigure these.

And, using the OPC UA HA specification, it is possible not only to read data with the current value, but also to query historical values in the OPC UA server, provided that server is storying history on items. An OPC UA client (such as Flow) that reads historical data points via OPC UA HA also transfers the desired time span to the server in addition to the data point information, providing the client access to the specific data and history for that data that is required.

When a data point is not currently being historized, Flow Software can even subscribe to real-time data in an OPC UA Data Access server and internally buffer that real-time information for the purpose of aggregation, contextualization, and calculation of that data for further analysis in similar fashion to the data coming from historical sources. This is useful in situations where additional tags are required to complete analytical operations where those aren’t readily available in already established process historian data sources.

So whether you’re working with OPC UA real-time or historical data sources, it is an open standard that facilitates interoperability of various systems, making OPC UA an important component of any Industry 4.0 initiative.

Conclusion

As you can see, there are many way to either take advantage of OPC UA technology you already have access to or enable your non-UA solutions to take advantage of the myriad benefits of OPC UA to bring your systems in line with Industry 4.0. With 27 years of experience with OPC in all of its specifications and use cases, Software Toolbox can help you get the most out of investments in OPC technology and keep those investments returning dividends for many years to come.

It’s important all OPC users consider how to migrate to OPC UA for the benefits of security, robustness, and multi-platform support, but also because of security changes Microsoft has made to DCOM, an underlying technology used in OPC Classic. All Software Toolbox OPC products (including the ones discussed in this article) already support OPC UA and have for many years, so contact us if you need to upgrade or want to discuss how we can help you in your journey to benefitting from OPC UA.