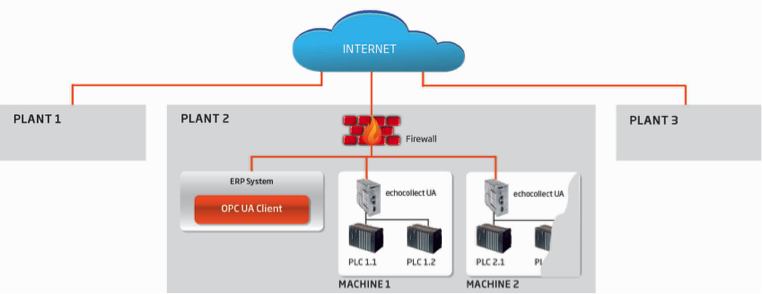

Thousands of Well Sites Collect Data via OPC

ABB was selected as the main automation contractor for the world’s first operation focused on converting gas from coal seams into liquefied natural gas. With several new wells being introduced every day, ABB needed to be able to bring them on and off line in a highly streamlined and efficient manner; furthermore, the method of configuring them needed to be simple, fast, and very reliable.