SPONSORED BY: OMRON

OPC UA has been adopted as a recommended standard for Industry 4.0, and the spread of OPC UA is progressing as a global interoperability standard that supports manufacturing and manufacturing DX (digital transformation) in the digital era. Thus, the spread of OPC UA is accelerating, and it is an important standard for both OMRON and OMRON’s customers. For this reason, OMRON began offering OPC UA server functionality in 2018, and is built-in as standard for their NX102 Series, NJ501 Series, and NX701 Series machine automation controllers. You can start using OPC UA with only a few settings without purchasing additional hardware modules or licenses. Because of this ability to use it easily, the introduction of OPC UA is expanding. We will introduce some of the use-cases.

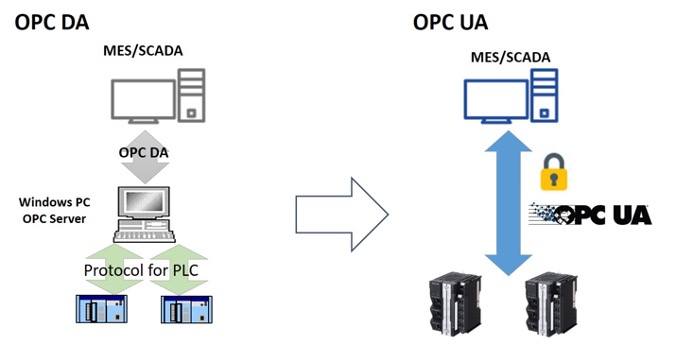

OPC UA Use-Case 1: DA to UA

Many of the first generation OPC technologies, OPC DA, have been widely deployed in supervisory control and operation monitoring of factories. As these systems get upgraded, the adoption of OPC UA increases. There are three key pieces:

- The direct connection with the control devices such as PLC is enabled, and the system configuration becomes simplified

- The ability to exchange not only simple numerical values and memory data, but also structured data and information with meaning

- Security can be improved

The increasing choice of SCADA, PLCs, and controllers that support OPC UA is also a driver for adoption.

OPC UA Use-Case 2: Securing Manufacturing Data

Taking advantage of the feature of OPC UA that it can handle security, it is effective as the method to avoid the falsification of manufacturing data to realize reliable manufacturing.

For pharmaceutical manufacturing lines and machines, it is beginning to be required to maintain the integrity of manufacturing data (Data Integrity: DI). Data integrity requires the assurance that all data is consistent and there are no inconsistencies.

In order to simplify the implementation of data integrity, OPC UA, which supports digital signatures, is being adopted for this purpose.

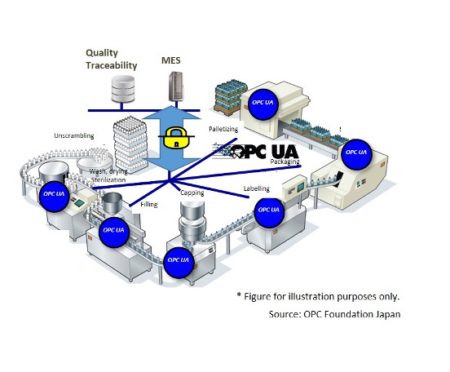

OPC UA Use-Case 3: Standardized MES Connection and Traceability

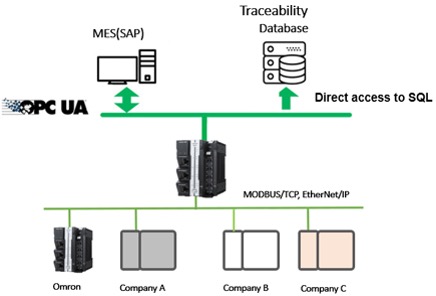

In a customer’s production line, many machines and devices of various manufacturers were installed, and the connection method between the upper system and the machines was not standardized. In order to standardize the method, the OMRON NX102 was retrofitted, and the connection with the MES (SAP) was standardized with OPC UA. The connection with the quality traceability database was standardized with the database direct connection feature. This system has been deployed in each plant as the global standard interface.

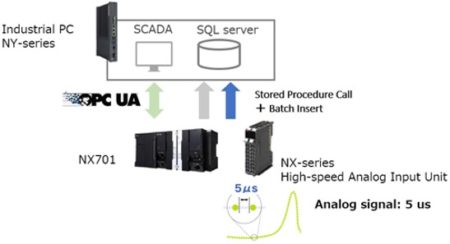

There is also an application where OPC UA is used in a machine. In the final inspection of automotive parts, the OMRON NX701 collects and analyzes the high-speed analog signals of tens of kHz required for judgment, stores all inspection results in a traceability database (SQL), displays the status and results using SCADA, and controls the transfer of the data. A direct connection to the database is used to collect and analyze the analog signals and store them in the database, and OPC UA is used to connect to SCADA to display the status and results.

OPC UA Use-Case 4: Machine Interface

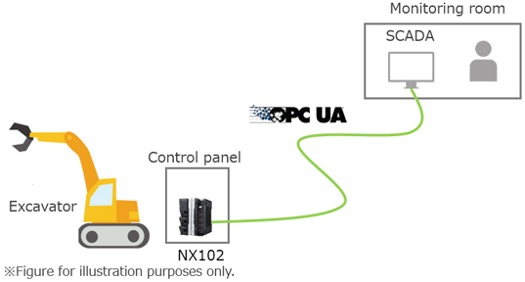

Remote Monitoring of Excavator

In order to remotely monitor an excavator used in an underground mine, the excavator and the SCADA in the monitoring room are connected by OPC UA. OPC UA is appreciated here because it is easy to connect and can be used without any complicated knowledge.

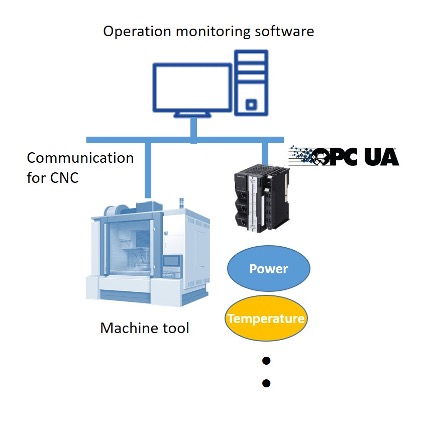

Operation Monitoring of Metal Machinery.

Here, OPC UA is adopted to gather and visualize the operation information of the machine tool, including a CNC. They are installed in a large number of metal parts processing lines, together with the information of the peripheral devices controlled by a PLC and the information of the operation environment such as power and temperature. The key point is that the information of both the CNC and the PLC can be collected and managed by one mechanism (OPC UA).

To contribute to the wide spread of OPC UA, OMRON is providing a web article that explains OPC UA in an easy-to-understand manner, along with the disclosure of such use-cases. It is available in English, Chinese (simplified), and Japanese.

English version

http://www.omron-cxone.com/dl/melma/?oc210412

Chinese version

https://www.fa.omron.com.cn/opcuasite

Japanese version

http://www.omron-cxone.com/dl/melma/?oc210411

Minoru OKA

Minoru OKA