SPONSORED BY: ICONICS

ICONICS was one of the earliest adopters of OPC and to date, is one of the most significant users of OPC. In this interview, Raymond Van der Tas, ICONICS Solution Sales Supervisor, explains the many ways the company has leveraged OPC to deliver its substantial features and benefits to users for a competitive advantage.

Raymond Van der Tas, ICONICS Solution Sales Supervisor

- How did ICONICS take the route of OPC?

Back in the nineties when we were looking into component object modeling, our choice was between IBM or Microsoft methodologies. We anticipated that users would be riding the Microsoft wave for decades so we defined a foundation based on COM. We invested in creating new technologies and shared a rapid development toolkit with OEMs to quickly leverage our developments. Our efforts were backed by the OPC Foundation, and a solid set of interfaces allowed us to move R&D resources from the server-side, to creating value on the client side. We marketed ICONICS solutions as “OPC-to-the-Core.” ICONICS products use OPC for both inbound and outbound communications, and we use it for time-series data, alarm management, history data access and connectivity-to-field equipment.

- How extensive is the integration between OPC and ICONICS?

As we connected address spaces of many device vendors, the need arose to create a unified name space. In 2000, we originally created DataWorX to allow the creation of a name space and we added functions like redundant node pairs, aliasing techniques, and internet connectivity. Since DataWorX acted as an OPC source, we allowed competing vendors to enrich their OPC solutions by integrating with our products and use DataWorX as an information aggregation and normalization tool.

- You discuss the benefit of a Unified Namespace which is a very hot topic these days, especially with the focus on OPC UA companion specifications for Information Models. How does ICONICS fit into this?

Today, the ICONICS solution for the Unified Namespace is called AssetWorX. It is becoming more and more crucial to provide access to data with context, so the data becomes self-explanatory and does not need a domain expert to explain it when needs arise. The purpose of AssetWorX is to create context where there may be none and to offer organized and robust aliases for information to ease data selection – reducing selection errors, and speed overall configuration.

- What are some interesting applications that have incorporated OPC?

We need to be clear that 100% of the applications with ICONICS solutions are using OPC. It’s internal to our products and not an option, as you see in some other solutions. All ICONICS industrial automation applications use OPC: all pipelines, all data centers, all breweries, all water treatment plants, all pharmaceutical plants, all airports, all machine builders. Even many building automation projects are based on OPC because the controllers used typically have a lower cost than those suggested by traditional vendors using BacNet. While ICONICS has some very powerful vertical market applications, our solutions are designed to address the market as a whole: for discrete, hybrid, and process applications. We have over 375,000 installations around the world.

- Are there limitations in size and what is the greatest number of OPC Servers?

An ICONICS solution has virtually no limit to the number of servers one may connect. There’s no commercial implication, other than a commercial point count may have to go to a next level of tags. We have had many large applications but what comes to mind is the Russian Transneft Pipeline that has hundreds of distributed nodes. Another example is a German car manufacturer in China that connects 600+ OPC UA sources to an ICONICS solution.

- How does tag count impact performance?

OPC leverages a subscription based nature which makes our software highly performant. This coupled with our 64 bit modern design (and it is amazing how few products have leveraged 64 bit operation for performance), let our products tackle extremely large jobs. But we also offer a scalable pricing model that is cost effective for small applications as well. We are engaged in implementations for some quite large applications at this time such as airports (e.g., Schiphol and Heathrow) and also as I mentioned earlier, in pipelines.

- What is the greatest distribution of a network?

I would say that the Russian Transneft Pipeline is the greatest. When we shipped the product, we included physical books. In preparation for shipping, many pallets with ICONICS products were placed in our office hallway, and our CFO looked at the shipment being prepared and asked: ”Will it work?”. I responded, “Don’t worry; it has to and will!”

- And what about the highest performance application?

Due to the change driven nature of OPC, performance is automatically optimized. However, if there’s anything to say about performance, it should be said by the OPC server vendor. Back in 2002, we believed we created the world fastest OPC server based on the ICONICS toolkit, and we donated the source code to another member of the OPC Foundation for incorporation into their products. OPC has proven to be extremely well performing, and our products are evidence of that.

- The use of OPC AE as both a client and server in ICONICS software is exceptionally powerful and differentiating. Can you comment on this?

If the 3rd party system is OPC UA or Classic A&E, ICONICS can subscribe and ingest. Obviously, our integrators prefer to use the ICONICS alarm generators since these are generally more feature-rich than 3rd party alarm sources. But the beauty of a standard remains that whatever the customer prefers, we simply subscribe. And of course, ICONICS also implemented ISA 18.2 in its alarm generator for use in managing large sets of alarms and documenting shift transitions in regulated industries such as Oil and Gas.

- What other tools are available for OPC performance monitoring or troubleshooting?

ICONICS products include TraceWorX to allow trouble shooting components at a detailed engineering level. To commission OPC solutions, the integrator or consultant may use the Data Explorer, a neat little tool to visualize any of the data sources (OPC alarms, OPC time series, etc.).

To get a feel for this, here’s a short 2-minute video the ICONICS team created:

- What are some differentiations for ICONICS implementations?

OPC is a natural fit for ICONICS solutions. One may connect 3rd party alarm servers and historians and leverage ICONICS functions like redirecting notifications to connected field workers through our solution called CFSWorX. You can visualize time-series data in ICONICS Trend Viewers, merge data into the Hyper Historian, or create a nice-looking app for a smart device to interact with the OPC sources. ICONICS IoT Edge devices connect OPC data sources and publish tag collections to a broker in the cloud for any 3rd party data subscribers. Our product in this area is called IoTWorX.

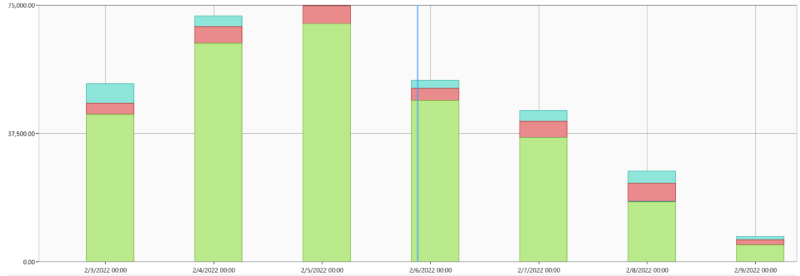

Hyper Historian is a very high performance Historian and is designed to reflect aggregates as defined in OPC Part 13, and allows users to quickly create dashboards to present hourly, daily, or monthly aggregates. The Hyper Historian can also act as a data source to 3rd party OPC UA clients. This is a highly significant area of differentiation with many other solutions on the market. ( Learn more about Data Aggregates). For example, while your historian may have high fidelity data for a variable, a weekly plot with daily aggregated values from the server is easy to create using our Hyper Historian and provides much better performance than transferring all the raw data to the requester for client-side processing. (See Figure 1.)

- It seems that many other vendors leverage OPC for third-party communications drivers. Does ICONICS do that as well?

Absolutely. We started life with a significant focus on communications. The development of OPC enabled some vendors to specialize in communications and have a standard interface for client applications. Names like Kepware and Takebishi come to mind. However, while we leverage third-party connectivity, we have also continued to deliver some of our own protocols, differentiating ourselves in some vertical markets. Moreover, connectivity is included natively without extra charge, in the standard value proposition for BACnet, SNMP, Modbus, Web Services, MQTT, AMQP, and JSON connectivity.

Wrap Up: What future do you see for OPC and ICONICS?

We see “OPC to the Core” as the DNA of ICONICS products and which is a technology that makes ICONICS HMI/SCADA and its associated products superior to those of other solutions with proprietary underpinnings. But it is important that customers realize that OPC is an invisible technology that makes products work. They don’t need to know how it works, but they do need to know that they will surely benefit from the consistent, full, and robust technology that the globally proven standard delivers.