SPONSORED BY: UTTHUNGA

Cloud computing has become increasingly popular in various industries in recent years due to its scalability, cost-effectiveness, and flexibility. However, migrating legacy systems to the cloud can be challenging, especially when dealing with different service providers and their proprietary interfaces.

One solution to this problem is using OPC UA (Open Platform Communications-Unified Architecture) as a cloud-neutral communication protocol. In this article, we will explore how OPC UA can help various industries to implement a plug-and-play cloud-neutral solution.

OPC-UA is a widely adopted standard for industrial communication that enables interoperability between different devices and systems. It provides a secure and reliable communication mechanism that can be used across heterogeneous platforms, operating systems, and network infrastructures.

OPC UA is built on a service-oriented architecture (SOA), which uses standardized services that any client can access. This architecture allows OPC UA to be highly flexible and scalable, as it is helpful for both point-to-point communication and complex distributed systems.

The key steps to develop a plug-and-play cloud-neutral solution using OPC UA are :

Step 1: Defining the Data Model: We must define the data model before building the OPC UA infrastructure. It represents the data structure exchanged between different devices and systems. This step is critical to ensure that all devices and systems use the same data structure and format. This step is also vital from the interoperability point of view.

Step 2: Implementing the OPC-UA Server: The next step is to implement the OPC UA server. This server utilizes the data model (from step#1) and provides standardized services that any client can use. The OPC UA server can be implemented by programming languages like Python, C++, or Java. The server can also be hosted on any platform – whether on-premises or in the cloud environment.

Step 3: Connecting the Devices: Once the OPC UA server is implemented, the devices must be connected to the server. This can be achieved using various communication protocols such as Modbus, Profibus, or Ethernet/IP. OPC UA provides a standardized interface that connects to the server and facilitates seamless exchange of data exchange across the industrial infrastructure.

Step 4: Implementing the OPC-UA Client: The final step is to implement the OPC UA ‘client’. Such a ‘client’ is responsible for consuming services offered by OPC UA server. Like OPA UA Server, this ‘client’ can be implemented using popular programming languages like Python, C++, or Java. It can be hosted on any platform – on-premises or in the cloud. The OPC-UA client can connect to multiple OPC-UA servers, which allows it to access data from different devices and systems.

One of the benefits of using OPC-UA for creating a plug-and-play cloud-neutral solution is that it provides a standardized interface for communication between different devices and systems. This means that we can easily integrate new devices and systems into the existing infrastructure without worrying about compatibility issues. OPC-UA also provides a secure and reliable communication mechanism that ensures data integrity and confidentiality.

Another benefit of using OPC-UA is that it allows us to easily switch between cloud providers without changing the entire infrastructure. This is because OPC-UA provides a cloud-neutral communication mechanism that is not tied to any specific cloud provider. Thus, it is quite easy to move our infrastructure from one cloud provider to another without modifying the underlying architecture.

The most important advantages of OPC-UA-driven solutions for various industrial applications are:

Interoperability: OPC UA is a powerful and accepted standard that delivers delightful results covering a host of industrial communication options. Hence, plug-and-play cloud-neutral solutions using OPC UA can seamlessly integrate with a wide range of industrial systems and devices. This interoperability ensures that data can be shared and processed between different devices and systems, improving efficiency and productivity.

Scalability: Cloud-neutral solutions using OPC UA are highly scalable. They can quickly adapt to changing business needs and requirements. As new devices or systems are added to the network, they can seamlessly integrate into the existing infrastructure without requiring extensive reconfiguration.

Security: OPC UA has robust security features built into the protocol. This ensures that data transmitted between devices and systems are protected from unauthorized access and cyber-attacks. This level of security is crucial in industrial environments, where sensitive data and critical systems are at risk from cyber threats.

Cost-effectiveness: OPC UA-based cloud-neutral solutions are more cost-effective than traditional integration methods. Further, they require less time and resources to set up, implement and maintain. Additionally, since OPC UA is a vendor-neutral standard, users are not tied to specific hardware or software providers. This leads to a high degree of flexibility and savings.

Future-proofing: As a widely accepted and standardized protocol, OPC UA will likely remain relevant and supported for many years. This means that plug-and-play cloud-neutral solutions using OPC UA are future-proofed, providing a reliable and sustainable solution for industrial communication needs.

Conclusion

Creating a plug-and-play cloud-neutral solution using OPC-UA is an excellent way to ensure interoperability between different devices and systems in a cloud environment. It provides a standardized, vendor-neutral way to achieve seamless connectivity and interoperability across devices, systems, and applications. This ideal approach has several advantages: reduced development time and cost, increased flexibility and scalability, and improved security and portability.

As digital technologies evolve and transform industrial applications, OPC UA will enable seamless communication and interoperability across different domains and platforms.

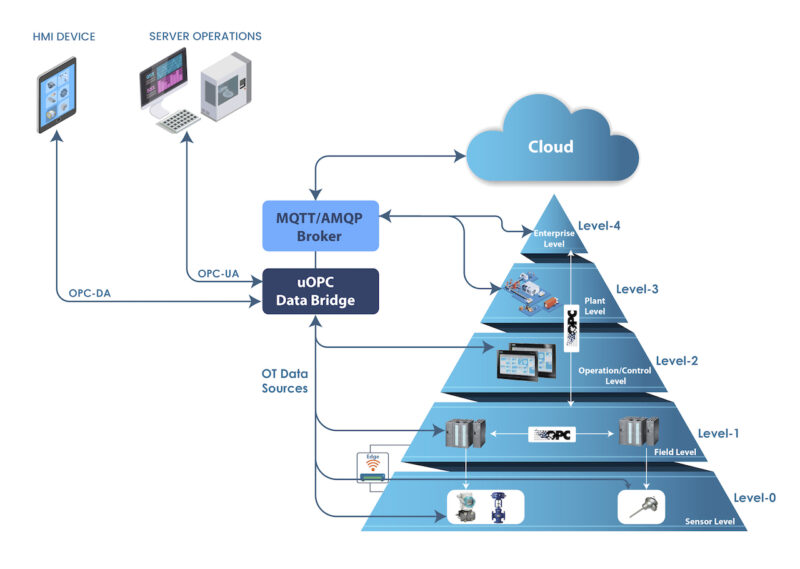

The success of OT-IT convergence in achieving complete and meaningful industrial communication depends on its intelligent integration with the cloud. Connecting field-device data with cloud applications helps enterprises make quick and informed decisions.

The uOPC Data Bridge, is a new product from Utthunga that delivers seamless OT-IT integration with enterprise solutions running on cloud platforms by subscribing to MQTT or AMQP brokers. The OT data is streamed to the cloud environment without configuring or decoding OT devices running on the vendor’s protocol.

About Utthunga

Utthunga is a corporate member of the OPC Foundation and has been a staunch proponent for the OPC standard and we continue to support 50+ industrial automation OEMs and organizations in their OPC implementation journey. Utthunga also actively contributes to OPC UA’s Field Level Communication (FLC) landscape and Field Exchange (FX) standards. To learn more about our OPC Products, visit https://utthunga.com/products/opc/