Digital Transformation at Groupe Renault

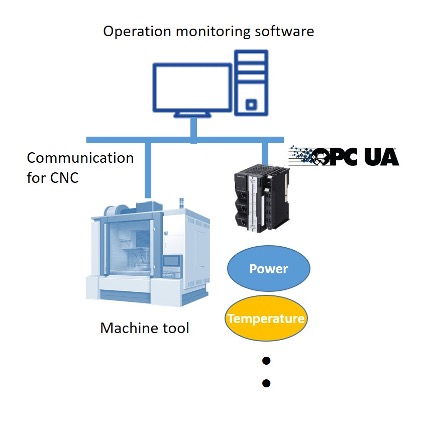

Groupe Renault’s plan is to implement the use of OPC UA-enabled devices and equipment at all production sites worldwide, and to implement end-to-end data communication from the sensor to the machines to the cloud and back again using the OPC UA communication standard.