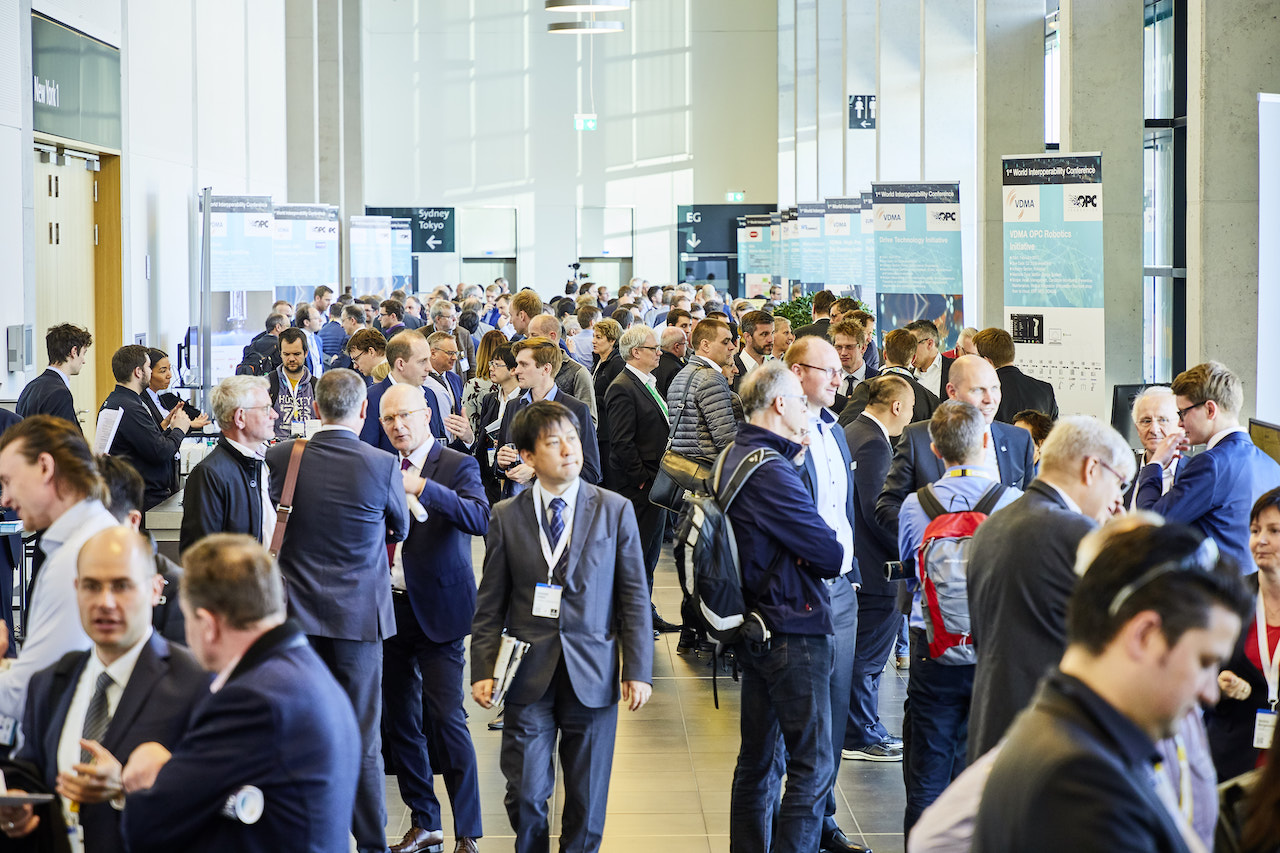

President’s Welcome

No matter in which part of the world you are, as a representative of the OPC Foundation you are always welcomed, since the challenge of industrial interoperability exists worldwide and can only be solved together. Global cooperation and harmonization are key tasks for the OPC Foundation going forward -not just across borders but inside vertical industries as well.