Sponsored by: Software Toolbox

The largest independent manufacturer of actuators in the world designs, develops, and manufactures electric mirror adjusting actuators and electric power-folding mirror actuators. Their main plant supplies most major European automotive companies. This facility recently upgraded their automation system by implementing the Cogent DataHub.

The largest independent manufacturer of actuators in the world designs, develops, and manufactures electric mirror adjusting actuators and electric power-folding mirror actuators. Their main plant supplies most major European automotive companies. This facility recently upgraded their automation system by implementing the Cogent DataHub.

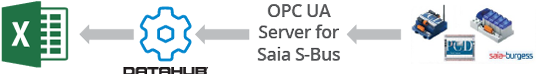

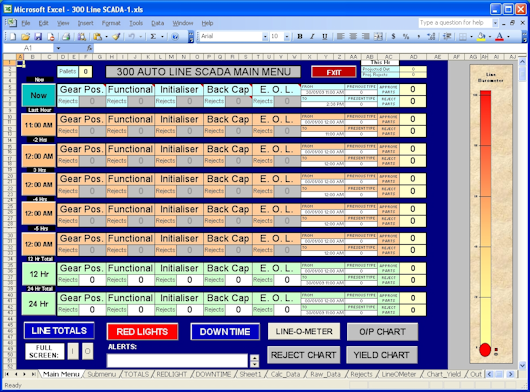

The company takes pride in developing its own ideas and solving its own problems. One example is the facility engineering team’s approach to collecting and viewing production data. On each of two production lines, the team has developed a system that collects production data and feeds it to some sophisticated Excel spreadsheets. The data flows from their Saia PLC to an OPC UA server for Saia S-Bus, and then to Excel, which compiles the data and charts hourly production totals, downtime, and product quality.

Useful as it is, the system has had a nagging problem for a while. “We’ve been developing our data monitoring system for several years,” said one of the engineering team members. “It works very well, but there was one downside -there were bugs in the Excel component that forced us to restart the PCs every so often.”

After much effort to work with, or work around, the faulty Excel component, the team finally turned to the web for a solution. When they found the Cogent DataHub, due to it’s OPC UA interfaces and Excel connectivity, they figured it might be possible to just drop it into their system and configure the reliable link to Excel that they needed. They soon realized that the Cogent DataHub could not only solve their problem, as intended, but was able to enhance their system in other ways as well.

“Setting this up was as simple as attaching the Cogent DataHub’s OPC UA Client interface to the OPC UA server for Saia S-Bus and making the connection to DataHub in Excel,” said the engineer. “And by replacing the troublesome Excel component with the Cogent DataHub, we were able to simplify the SCADA system into a single workbook. What’s more, since the DataHub can be run as a service, our operator now only needs to open a workbook to have the entire system up and running.”

“Here’s how it works,” continued the engineer. “The Cogent DataHub feeds raw data into a column of cells in the ‘RAW_DATA’ sheet of the workbook via the Skkynet Vine plug-in for Excel. Then an Excel macro triggers every hour, causing the cell values to shift one column to the right. After 24 hours, the data begins to roll over on an hourly basis. Since the PLC counters do not reset, a separate ‘CALC_DATA’ sheet calculates the difference between each hour column and thus determines the actual count value to display. All other worksheets are a manipulation of this data for display purposes—graphs, tables etc.”

And because the Skkynet Vine plug-in for Excel doesn’t rely on legacy DDE technology, coupled with the robust security of OPC UA, the system is now extremely secure and reliable going into the future.

“We are very happy with the software,” said the engineer. “It’s stable and secure. A big plus for us is a high degree of confidence that prompt technical support is available from Software Toolbox and Cogent when we need it. That was not the case with our buggy Excel plug-in. Now the system is up and running with the Cogent DataHub, and we haven’t had to restart the PCs at all.”

If you’re not familiar with Cogent DataHub but the use case above is intriguing to you and you would like to try DataHub for your own OPC UA and other integration projects, you can get a free trial of Cogent DataHub. Click to Download Your Free Trial.

Cogent DataHub is a trademark of Cogent Real Time Systems. Software Toolbox is a trademark of Software Toolbox, Inc.