umati: universal machine tool interface

There‘s no better connection than that of a common language – which is also true for machine tools. The easier they exchange and share information, the more efficient they are.

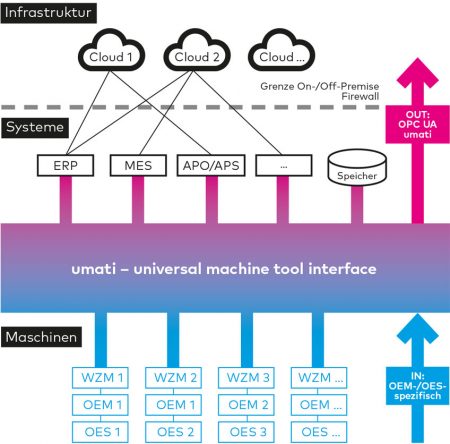

In a joint effort, 17 partners and VDW created umati (universal machine tool interface). It enables machine tools and peripherals to connect to customer-specific IT ecosystems – easy, secure, and seamless. umati is an open standard for machine tool users throughout the world. It serves to exploit new potentials for manufacturing of the future.

After launching the project in September 2017 at EMO Hannover, machine tool builders Chiron, DMG Mori, Emag, Grob Werke, Heller, Liebherr Verzahntechnik, Trumpf and United Grinding committed themselves to the working group. Application partners GF Machining Solutions, Pfiffner and control technology experts Beckhoff, Bosch Rexroth, Fanuc, Heidenhain, Siemens share their know-how as well as IGH Infotec AG and the ISW at Stuttgart University.

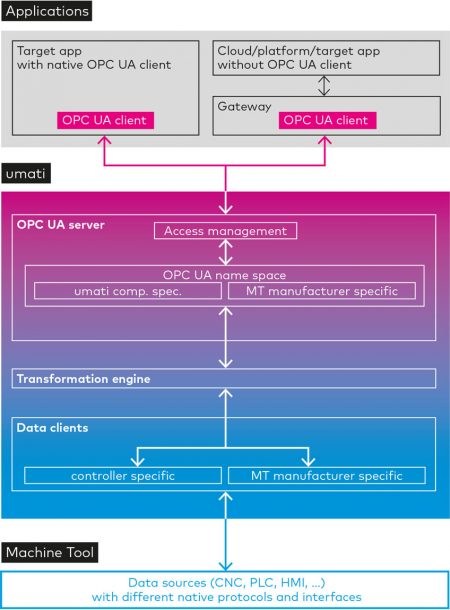

Individual mapping and transformation based on OPC UA

umati is based on an OPC UA companion specification. OPC UA is the ideal communication platform for different industrial devices due to its open data model. In addition, umati realizes customer or manufacturer specific mapping and transformation of parameters through standardized configuration.

Experience umati live at AMB 2018

AMB 2018 is the place where umati is entering the world. At the central information booth within the Digital Way

special exhibit (DW088), visitors can learn what the new brand is about and see how a centralized interpretation of standardized data can be done using for example X-NetMES by IGH Infotec AG. Implementations of the common interface can be experienced at the project partners’ booths throughout the show. They feature various machines and controllers which connect to a variety of communication partners.

The demo applications which are on display at the AMB Stuttgart were devel- oped by a core team of eight renowned machine tool suppliers together with the major German control manufacturers. Within one year they have established more than 100 parameters which serve as the basis for developing the common interface. The working group was also able to define 21 use cases for the new standard interface for machine tools based on the open OPC UA communication protocol.

The companies involved in the initiative integrated an appropriately configured OPC server into their respective machine control system and were “able to connect to the respective communication partner and exchange data in a very short time,” Prokop was pleased to report. Up to now it has been very time-consuming and costly to get machines from different manufacturers to communicate with each other on a single production line.

The first connections to various controls – for example for vertical lathes, rotary transfer machines, gear milling and grinding machines and for a complete turning/milling machining centre – will be on display in Stuttgart. “Our purpose with these applications is to demonstrate that our solution can be used to implement robust systems in which data can reliably be exchanged with machine tools,” explained the VDW Chairman. “We ourselves are also keen to gain practical experience as early as possible and learn from the challenges which emerge.”

Internationalization making good progress

Launched as a purely German working group, international cooperation has, however, always been the goal of the industry initiative. The initiative is attracting a great deal of attention worldwide. For example, talks are underway with the US sister association AMT, especially with regard to its open interface MTConnect. The extent to which parts of this can be used in umati or whether both standards can be aligned in the long term is currently being assessed. Japan, China and South Korea have also expressed interest in the new standard. “We regularly report on the project progress at meetings of the European Machine Tool Association Cecimo, and are keen to include other interested companies in the initiative,” said Prokop.

Significantly, the VDW joined the OPC Foundation (the OPC UA sponsor) in June. “At the turn of the year, we will set up a Joint Working Group with the OPC Foundation,” Prokop announced. “The international machine tool community will then be able to participate in revising and disseminating the standard. This feedback on customer needs from all over the world will bring us a further important step closer to our goal of creating a uniform, globally accepted connectivity standard.”

Learn more at http://umati.info