Open Shared Source Code and Specifications Program

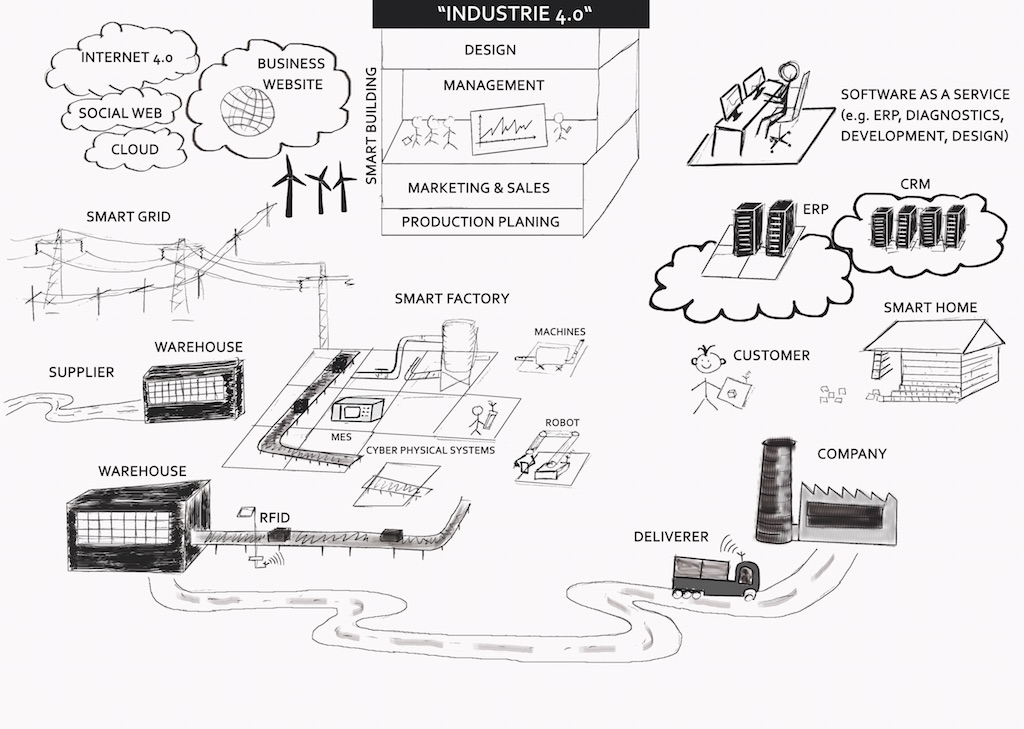

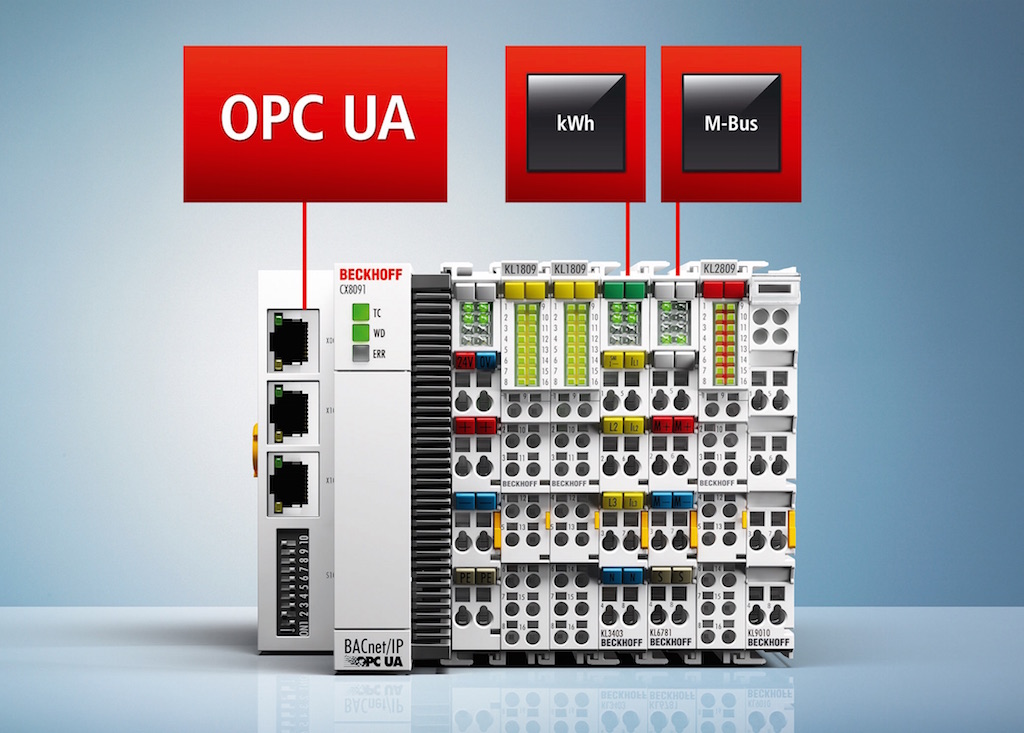

The OPC Foundation opens the doors to facilitate increased adoption of OPC Unified Architecture technology beyond industrial automation! The OPC Foundation is implementing an “open shared source” strategy…